General

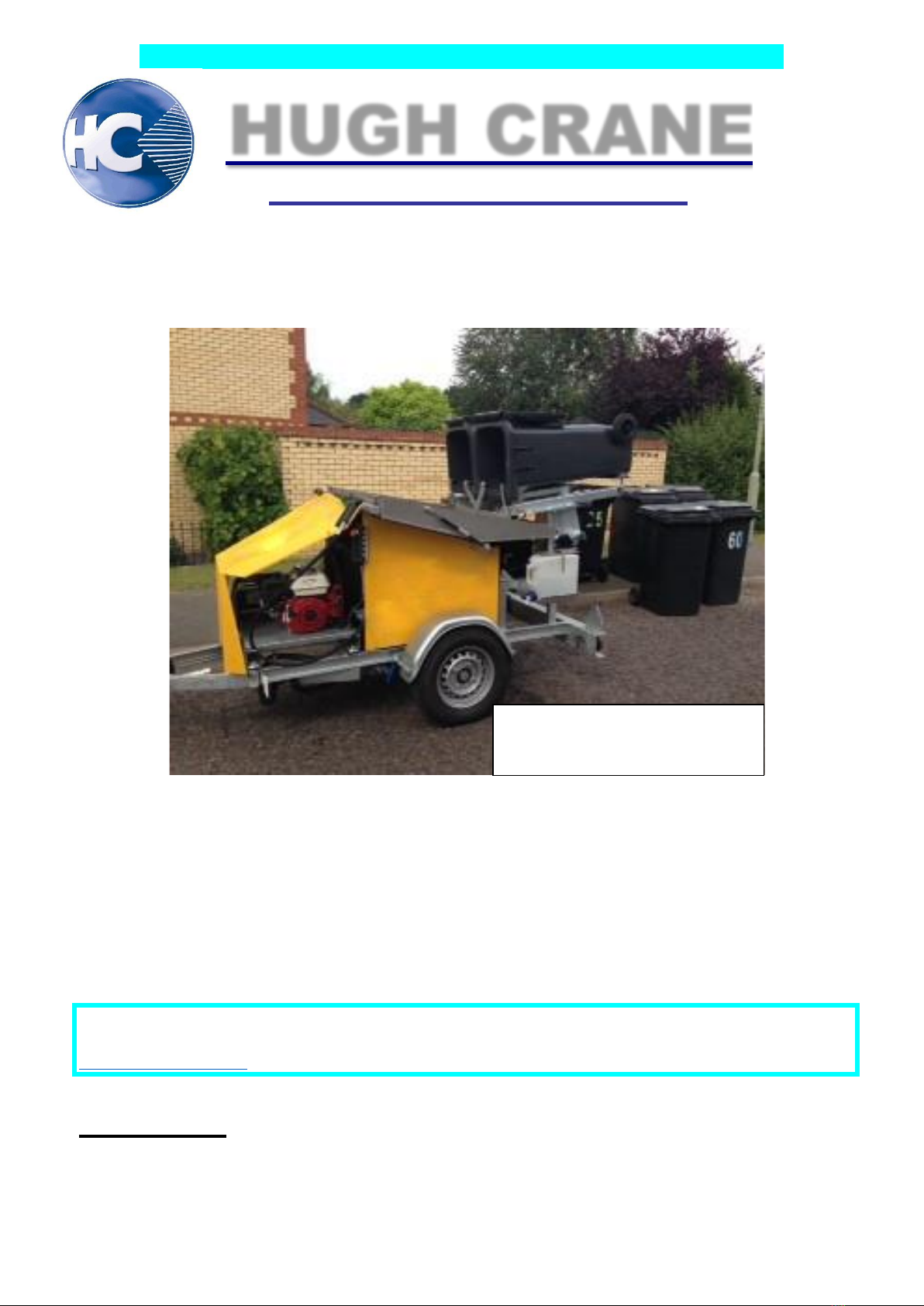

This equipment/machinery is designed and constructed for the general cleaning of plastic

waste bins, designed and constructed to EN840, of sizes 140/240/360/600/1100 litres only

that have not contained hazardous wastes. For any other bin types, Hugh Crane Cleaning

Equipment should be contacted for approval before proceeding.

It is not intended to, nor does it, clean to a standard that would either be considered as

hygienically clean or “food safe”.

It should only be used by persons trained and competent in its operation in accordance with

the instructions within this manual, and should only be maintained / repaired by persons

trained and competent to do so, following the isolation and making safe of the equipment as

detailed within this manual.

The machine must not be misused in any way, nor any hazardous areas accessed, for

example beneath elevated bins, during operation.

The machine should only be used in a safe location away from other persons not involved in

the bin cleaning operation and a safe working area should be established with other persons

kept away.

The machine should not be left unattended where there is the possibility of operation by

unauthorised persons without stopping the engine and removing the ignition key, which will

prevent use of the machine.

Safety in Operation

This equipment/machinery is designed and constructed for the general cleaning of plastic

waste bins, designed and constructed to EN840, of sizes 140/240/360/600/1100 litres only

that have not contained hazardous wastes. For any other bin types, Hugh Crane Cleaning

Equipment should be contacted for approval before proceeding.

•It should only be used by persons trained and competent in its operation in accordance

with the instructions within this manual with all guards in place and other safety features

working effectively.

•Only disconnect from the tow vehicle and operate on firm level surfaces.

•The handbrake must be applied when uncoupled from the tow vehicle and rear support

legs lowered/deployed before use is commenced.

•When refuelling remember that petrol and petrol vapour is extremely flammable/explosive.

Allow engine to cool before adding fuel, only do so in well ventilated areas (outside), avoid

other potential ignition sources, use funnel to minimise spillage.

•Only operate/use outside or in other well ventilated locations where exhaust fumes cannot

accumulate to hazardous levels.

•Bins should be checked and emptied before attaching to the unit.

•Bins should only be attached, elevated and returned to their upright position with the

operator having full view of the operating area, ensuring that he and all others are clear of

the area while these activities take place, notably away from:

oThe bin clamping and elevating mechanisms

oThe space below the bin when elevated

oFrom between the bin and the frame when the bin is being lowered.

•Do not release the bin clamp with the bin in its elevated position.

•The high pressure cleaning jet should only be used for bin and associated cleaning tasks

with other persons well clear of the water jet and any aerosol produced. The jet should