Summarizing the operating instructions:

1. Inspect the system for damage. Check oil/fuel levels.

2. Attach the garden hose to the unit.

3. Start pressurized water supply and ensure that the system is primed.

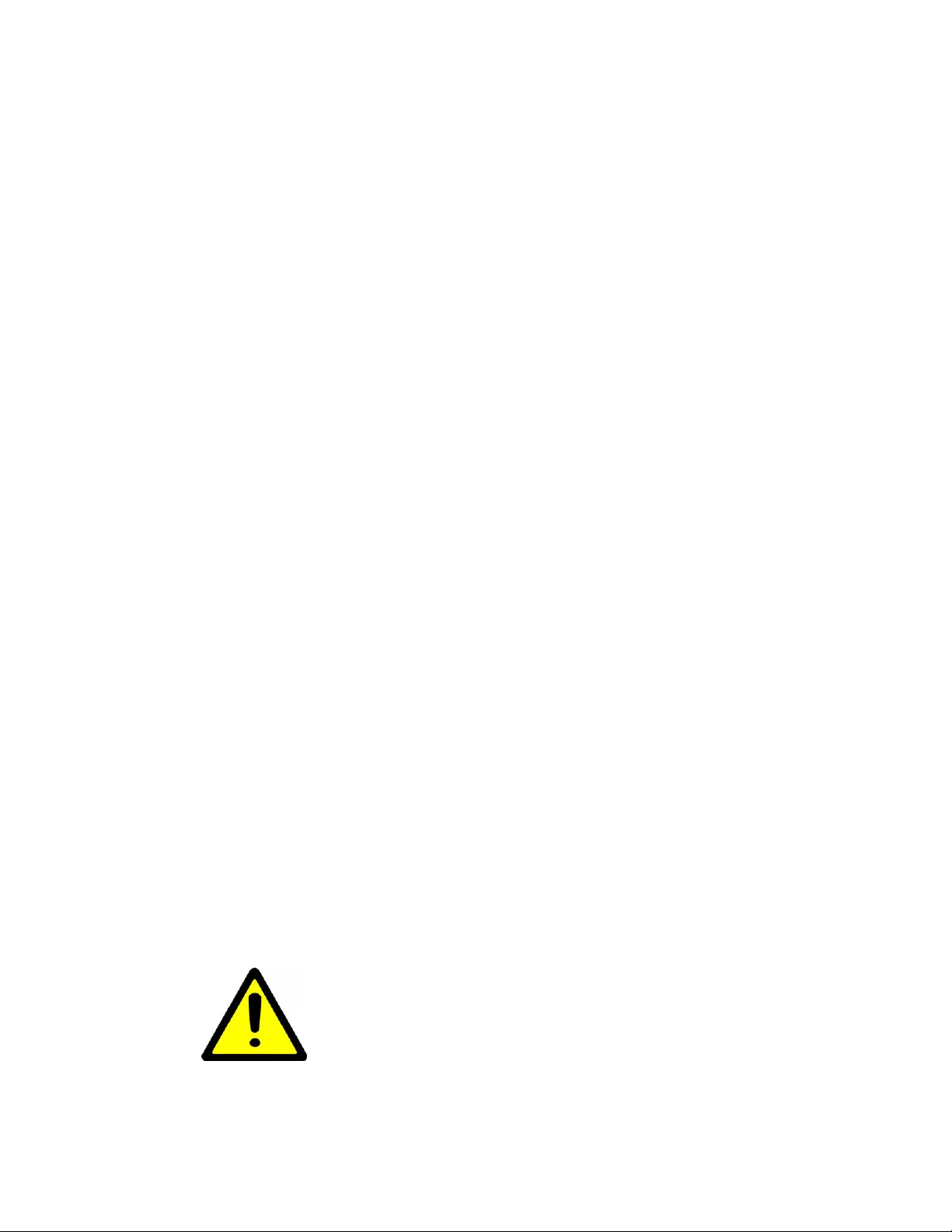

4. Attach the gun to the pressure hose.

5. Make sure that the diver is ready to work and that the gun is submerged in the water.

6. Apply hearing protection, start the engine and adjust the throttle to “MAX.”

7. Activate the cleaning cavitation stream by squeezing the gun trigger to open or “on.”

8. Proceed with cleaning.

9. When cleaning is complete, shut off the pressurized water source.

10. Release pressure from the hose(s) by squeezing the gun trigger to the open or “ON” position while

under water.

11. Remove the gun from the water.

12. Flush the system and rinse the outside of the power unit with fresh water.

WARNING: While the CaviBlaster® system is very safe, operators should exercise care when using this

equipment. With the diver lance underwater, the cavitation “flame” can be safely passed

over the operators’ skin at normal operating distances of 2” – 3” from the tip of the nozzle.

However, at very close distances (typically less than 1”) both nozzles can cause harm to

the operator, particularly in the initial instant that the system is activated. For that reason,

operators should exercise caution when operating the gun with the nozzles in close

proximity to the body. The operators should also ensure that the reverse-thrust nozzle

guard is secured in the correct position prior to operating the gun. The operators of the

CaviBlaster® system should always wear neoprene or heavy rubber gloves to provide

protection to the hands and, in particular, to the nails. The gloves will absorb most of the

energy produced by bursting cavitation bubbles and prevent the cavitation bubbles from

contacting the operators’ hands. The gloves will also protect operators’ hands from the

initial shockwave when the gun is activated. Serious harm and injury may result from the

misuse of CaviBlaster® system equipment or improperly selected fittings, hoses or

attachments. All components of the system should be checked against the

manufacturers’ instructions to ensure that they are compatible with the pressures being

used and of the correct thread type and pressure rating for the intended service. Refer to

these Operating Instructions and to the engine and pressure pump manufacturers’

operation manuals for instructions or call CaviDyne, LLC at (352) 275-5319 with any

questions.

CAUTION: DO NOT USE IT TO CLEAN SENSITIVE SURFACES as LED-

Lights, Underwater Lights, Electronic Equipment, Etc.