HUGH CRANE (Cleaning Equip ent) Ltd – COMMANDO

®

4000 Page 6

a) Before using the COMMANDO

®

4000 operators should have undergone basic training

in the safe use of high pressure washing equip ent. Training courses are available

fro Hugh Crane (Cleaning Equip ent) Ltd. if required.

b) Suitable protective clothing should be provided and worn by all operators.

High-pressure jets are dangerous if subjected to misuse.

Care should be taken to ensure that ani als and children are kept well out of the

working area. The jet must not be directed at people, ani als, the achine itself,

non-waterproof, fragile ite s or electrical equip ent.

c) User’s attention is drawn to health and safety guidance note P.M.29 which deals with

the use of high pressure cleaners and stea cleaners. Eye protection to BS2092/2

ust be worn when this equip ent is used.

d) All repairs to this equip ent ust be carried out only by suitably qualified personnel.

No odifications or changes to the specification of this achine should be ade

without prior consultation with and approval of the anufacturer.

e) The achine is supplied with guarding in co pliance with current legislation. The

achine ust not be operated with any of the guards, covers or any other safety

equip ent re oved or da aged.

f) Co ponents that are supplied by others, such as the engine, are covered by

individual anufacturer’s infor ation, which is included for your use.

g) Che icals ay be used in conjunction with this equip ent using a che ical injector.

Only che icals supplied or reco ended by the anufacturer should be used, as

other products ay affect the safe use of the equip ent. Consideration should also

be given to environ ental and COSHH regulations.

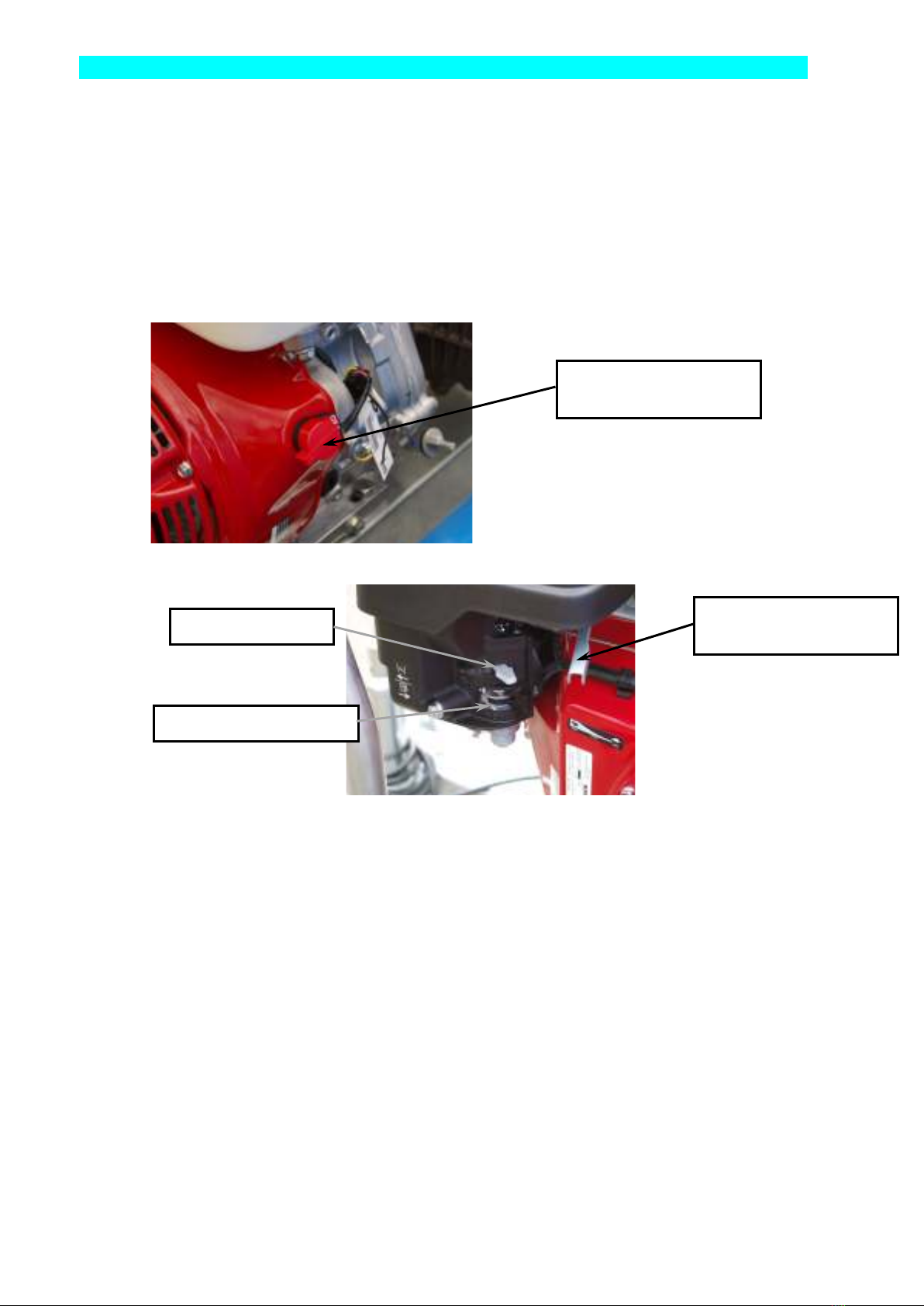

h) The high-pressure spray gun is provided with safety lock, which enables the trigger to

be locked off to prevent inadvertent use.