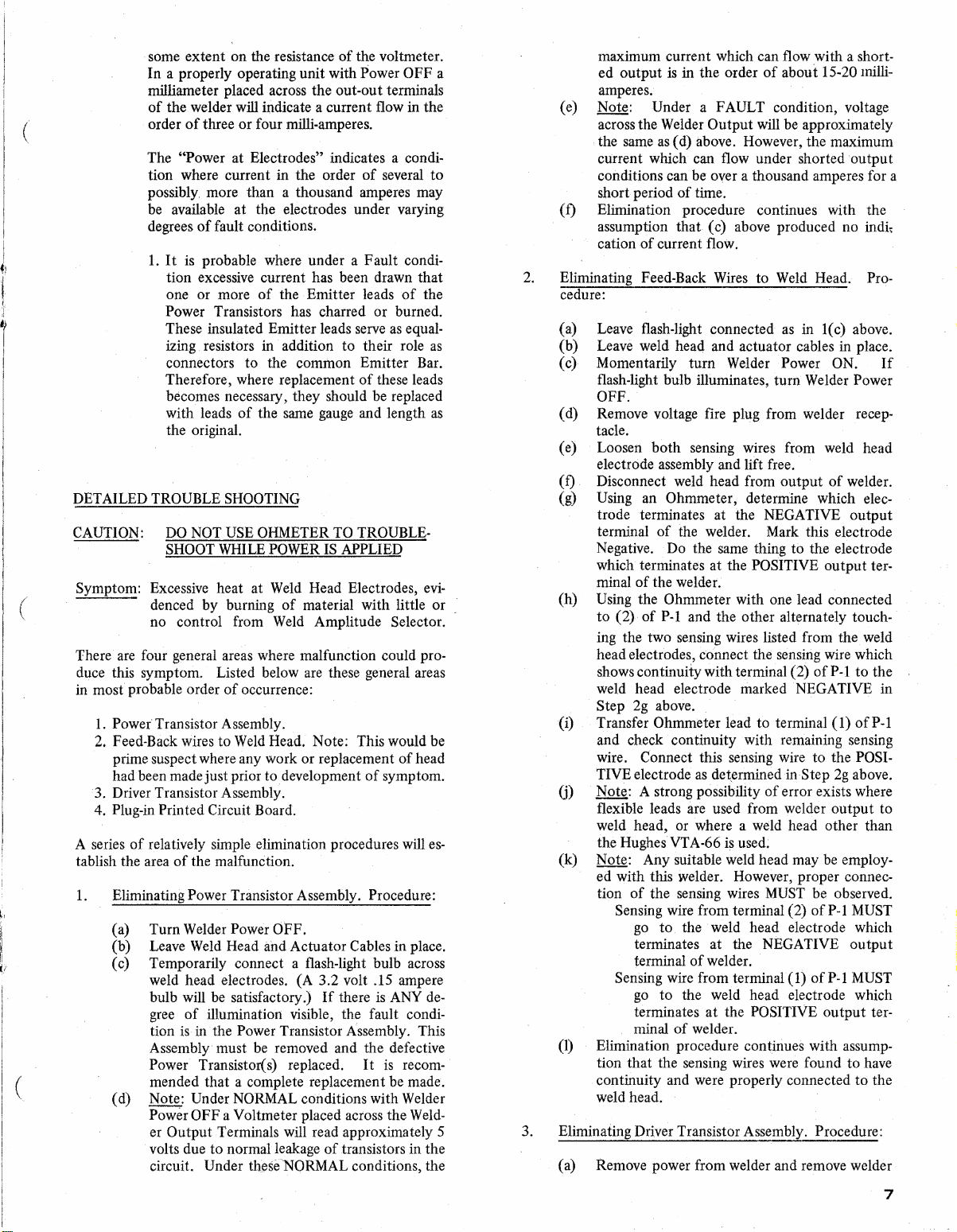

SYMBOL

R27

R29A

R29B(9)

R29c(9)

RTB(9)

RTA(9)

R33

R39

R40,R41

R43

R44

R45

R47,R42

R48

C1,C2,C3,C4,

c6,c7

C5

Cg

C9

Crn,C11

C12

C13

C14

CT1

CT2

CT3

,cT

4

,cT

5,

CT

6

,CT

7

F1,F2

F3

DESCRIPTION

Resistor, Fixed, Composition

Resistor, Fixed, Metal Film

Resistor, Fixed, Metal Film

Resistor, Fixed, Metal Film

Resistor, Fixed, Metal Film

Resistor, Fixed, Metal Film

Resistor, Fixed, Composition

Resistor, Fixed, Wire-Wound

Resistor, Fixed, Wire-Wound

Resistor, Fixed, Composition

Resistor, Fixed, Composition

Resistor, Fixed, Wire-Wound

Resistor, Fixed, Composition

Resistor, Fixed, Composition

Potentiometer, Wire-Wound

Potentiometer, 15 Turn Wire-Wound

Potentiometer, 15 Turn Wire-Wound

Resistor, Fixed, Composition

Resistor, Fixed, Wire-Wound

Capacitor, Tubular, Mylar

Capacitor, Disc Ceramic

Capacitor, Metalized Mylar

Capacitor, Metalized Mylar

Capacitor, Tubular, Electrolytic

Capacitor, Tubular, Electrolytic

Capacitor, Tubular, Electrolytic

Capacitor, Tubular, Electrolytic

Capacitor, Tubular, Mylar

Capacitor, Tubular, Mylar

Capacitor, Tubular, Mylar

Fuse, I

AMP

-

AGC

Fuse, 2

AMP

-AGC

Pilot Lamp, NEON

Receptacle, 4 Pin, Male

Receptacle, 4 Pin, Female

Output

Receptacles

Power Outlet and Receptacle

HACPARTNO.

590H182

590Hl84

5908195

590H199

590H197

590Hl98

590H201

590H159

590H160

590HI85

590H183

590H203

590Hl78

520H027

520H029

520H028

520H073

590H205

200H0S3

200H054

200H057

200H056

200H058

200H059

200H060

200H061

200H012

200H026

200H028

310H027

310H029

420H017

550H020

550H002

WO

2042

SS0H021

VALUE

300OHM

lK

lO0OHM

IOOHM

IOK

100K

1/2W

5%

1/2W

1%

1/4W

1%

1/8W

5%

l/4W

1%

1/4W

1%

I.SK lW

5%

l0OHM

5W

lOHM

2.2K

560OHM

3.0OHM

47OHM

150

OHM

300OHM

lK

200OHM

lO0OHM

25OHM

.01 MFD

.001 MFD

2MFD

1 MFD

250MFD

S0MFD

l00MFD

20KMFD

.1

MFD

IMFD

2MFD

SW

1/2W

5%

1/2W

5%

IOW

1/2W

5%

1/2W

5%

SW

1/2W

l/2W

2W

5%

SW

50V

±10%

SOOY

±10%

100V

10%

100V

10%

12V

SOY

25V

25V

100V

10%

lO0V

10%

lO0V

10%

(

\ (

( (

( (

SECTION

II

OPERATION-

MCW-550

CONTROLS

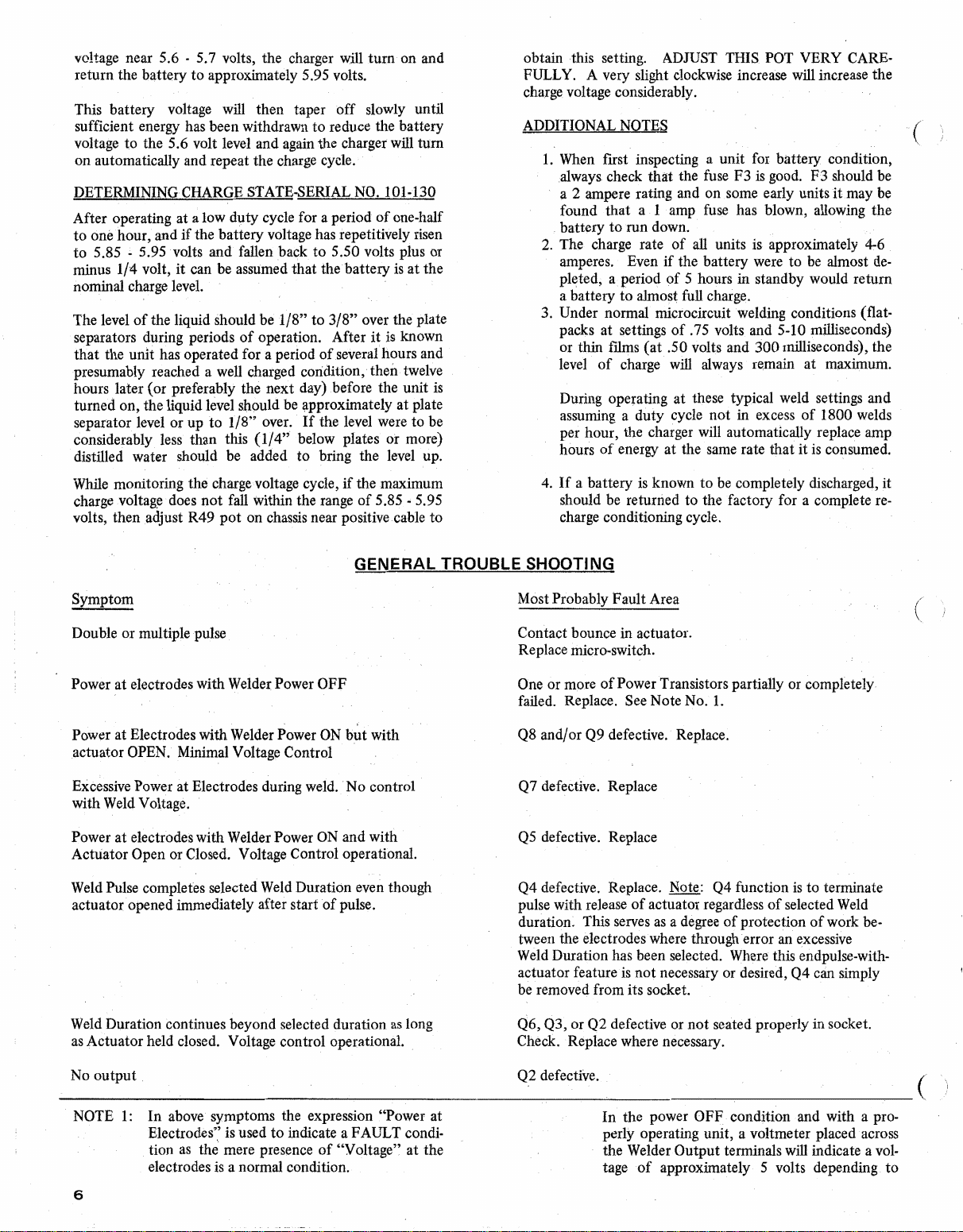

Optimum welding results can be obtained by varying weld

duration and electrode force and gap settings. Further

refinements can be made by adjusting the third voltage

>1 control thumbwheel for variations from .01 volts and

~

up.

Operation

of

the Model

MCW~SS0

.Constant Voltage

\V)\

Welding Power Supply is extremely simple

..

There are

o.nly

\;S

~

NOTE

two adjustable controls,

Weld

Voltage and Weld Duration.

~

\.~

The power supply makes

no

audible sound when

discharged.*

At

lower power levels, little or

no

effect will be noticed upon the materials being

welded.

In

addition

to

the main power switch, there is also an

Illuminator lamp switch and an auxiliary power switch

(connected

if

·a

vacuum pump is incorporated within the

power supply

or

other accessories).

An

external vacuum

pump may be connected

to

the front panel power switch

with hose take

off

thru the front panel ports

if

no integral

pump is installed.

CONNECTION

Prior

to

first energizing the power supply, connect the

weld head

to

the front panel receptacle with either cables

or

gold-plated copper bus bars

as

supplied for Hughes weld

heads. When using Hughes Model VTA-66 weld head,

connect 4 pin plug from head

to

the "Voltage-Fire"

receptacle·.

If

other Hughes welding heads having 2 pin plugs (such

as

Model VTA-60, VTA-62, VTA-64, or VTA-66-MA) are used

with this equipment, some provision must be made

to

connect the actuator firing circuit and the voltage feedback

circuit

to

the Voltage-Fire receptacle.

WARNING -SPECIAL NOTE:

IT IS IMPERATIVE

that

the feedback voltage wires

connecting· from the weldhead electrodes

to

pins in

the plug going

to

the Voltage-Fire receptacle be

connected with the proper polarity.

WHICHEVER ELECTRODE IS POSITIVE MUST

BE

CONNECTED TO PIN 1 in the plug

to

the Voltage-

Fire receptacle. THE NEGATIVE ELECTRODE

MUST

BE

CONNECTED WITH A FEEDBACK

WIRE TO PIN 2 in the Voltage-Fire plug.

With dual head systems,

b&

sure

to

observe polarity

marking on cables which will have RED dots indi-

cating the positive cable. The corresponding posi-

tive terminal

on

a VTA-66 or VTA-90 weld head

will also have a RED

dot

on

the end

of

the positive

stud.

DO

NOT ATTEMPT

TO

OPERATE THIS POWER

SUPPLY WITHOUT THE VOLTAGE FEEDBACK

WIRES BEING PROPERLY CONNECTED FROM

THE WELDING ELECTRODES TO THE FRONT

PANEL "VOLTAGE-FIRE" RECEPTACLE.

TYPICAL

OPERATION

Set

"Weld Voltage" thumbwheels

to

approximately

.30

volts.

Set

"Weld Duration"

to

S milliseconds.

If

a

VTA-66

wdd

head is being used, set

for

4 lbs. pressure

and electrode gap

of

.020". Test welds should be made

starting from these settings. Using the middle thumb-

wheel

of

the voltage control, increase settings in incre-

ments

of

.10 volts until some visible welding results occur.

DO

NOT OVERPRESSURE the electrodes in an attempt

to

"fire"

the welder.

Increase voltage and/

or

time in small increments between

test welds until satisfactory results are observed.

CAUTION The MCW-550 power supply will deliver

current

to

the limit

of

its ability in order

to

produce· the preset voltage. Since this

current may exceed 800 amperes, extreme

care must be taken to prevent the electrode

gap from shorting. Damage

to

the

elec-

trodes will be immediate

if

the power supply

discharges with the electrode gap set

at

zero.

Avoid setting the weld voltage to a high level and long

weld durations

at

the same time. Weld voltage settings

of

over ONE VOLT combined with weld duration settings

greater than 100 milliseconds will produce extreme heat

at

the electrodes.

Most microcircuit welding applications will be within the

range

of

.SO

-.85 volts setting and 5 -15 milliseconds weld

duration, or .20 -.50 volts

at

50

-

350

ms duration.

DO NOT EXCEED A VOLTAGE SETTING OF

.50

VOLTS

IN

COMBINATION WITH TIME DURATIONS BETWEEN

250

-500

MS

FOR

NORMAL WELDING.

NEVER discharge power supply with very low resistance

material beneath electrodes, such as heavy copper, brass

or steel plates.

* Sonalert audible indicator available from factory

in-

stalled in original equipment on order or also

avail-

able

as

field

mod

kit.

SECTION Ill

ELECTRICAL &

MECHANICAL

SPECIFICATIONS

MCW""""550

TYPE

OF POWER SUPPLY:

Constant voltage -direct current -square wave output.

WELDING PULSE CONTROLLED RANGE:

Time Duration: Adjustable from I -

9900

milliseconds in

three ranges.

Low Range: 1 -

99

milliseconds

Middle Range: 10 -990 milliseconds

3