Quick Start Guide 4

Unpacking

Installation and Equipment Setup 4

Electrical Connections 4

Power Switch 4

Instrumentation Connections and Setup 5

HM-58120 Rear Instrumentation Panel 5

Network 5

USB Power 5

Instrument Inputs 5

Initial Set-up 7

Instrument Inputs 7

Initial Set-up — Calibration 8

Calibration Input Screen 9

Units 10

Value 10

SignicantDigits 10

Export Calibration via USB 14

Initial Set Up — Date/Time 15

Date 15

Time 15

Clock Style 15

Clock 15

Initial Set Up — Display 16

Brightness 16

DimDisplay 16

TurnDisplayOff 17

Initial Set Up — Preferences 17

Preferences–GeneralTab 17

LoggerID 17

Sound 18

Preferences–SystemUnitsTab 18

Ambient Temperature 18

Motor Speed Unit 18

Stress Control Unit 18

Preferences–SpecimenParametersTab18

Specimen Height 19

SpecimenDiameter 19

Preferences–StorageTab 19

Test Storage Limit 19

Recycled Tests 20

Test Templates 20

Save to USB Check Box 20

Initial Set Up — Network 20

Network Settings Screen 21

DHCP 21

IPInformation 22

Local Status 22

Internet Status 22

Initial Set Up — Information 22

SystemInformation 23

FirmwareVersion 23

IPInformation 23

LocalStatus 23

InternetStatus 23

Memory 23

FactoryScreen 23

ExportLogFile 23

Initial Set Up — Contact 24

ContactInformation 24

Initial Set Up — Update 25

UpdatefromUSB 25

CheckforUpdate 26

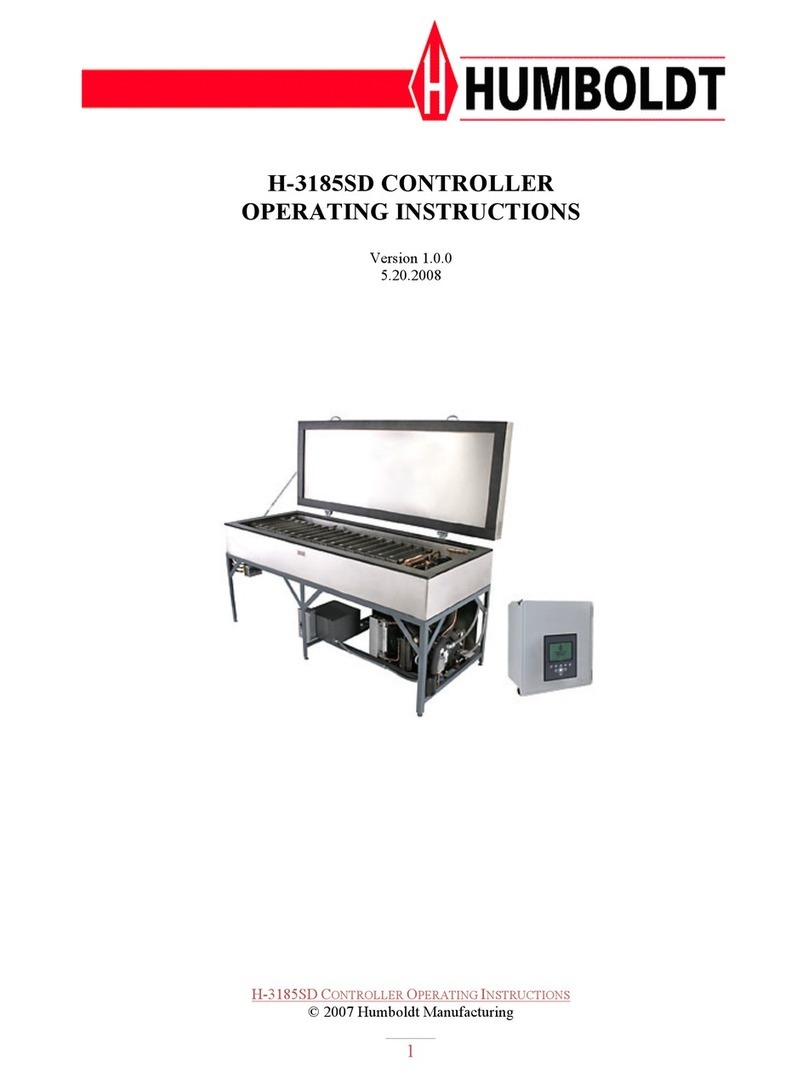

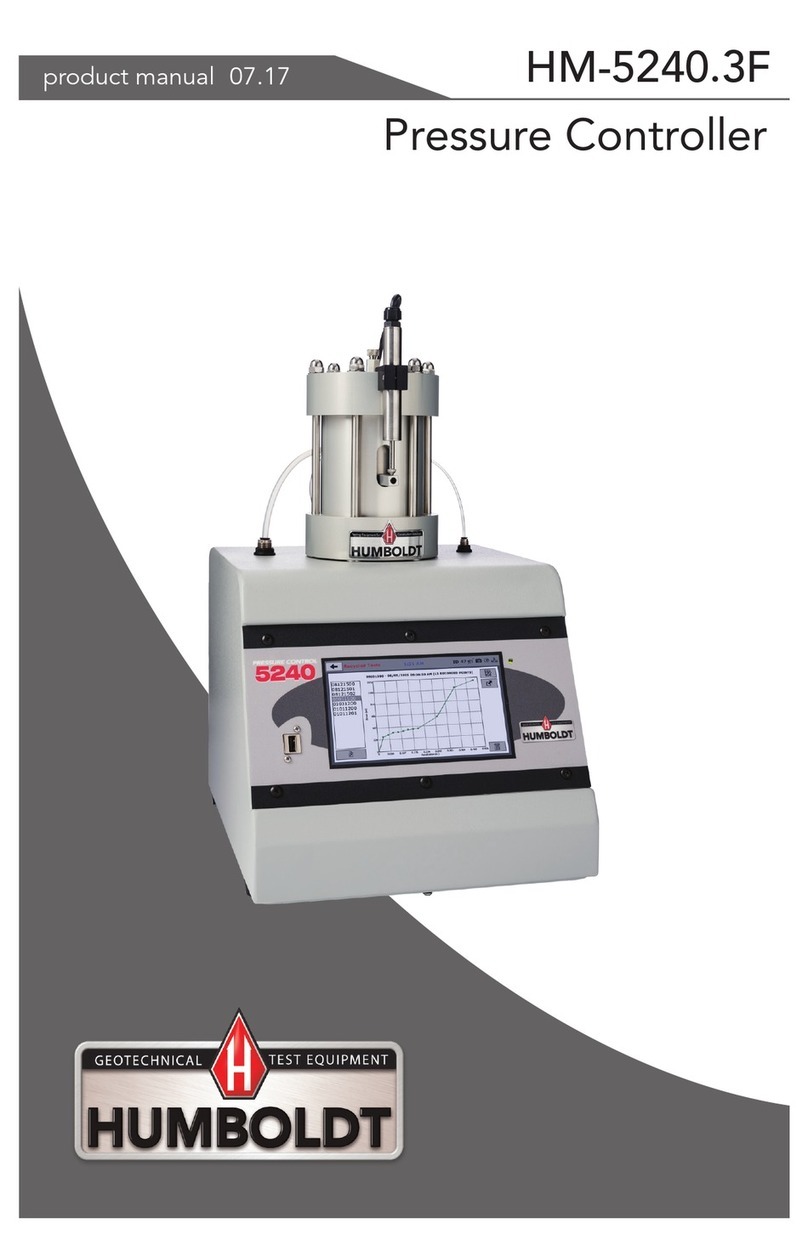

Equipment Setup 27

Installation and Equipment Setup 28

Electrical Connections 28

Power Switch 28

Instrumentation Connections and Setup 28

Rear Instrumentation Panel 28

Network 29

USB Power 29

Instrument Inputs 29

Instrumentation Setup 30

Third-PartyInstrumentation 31

Calibration of Instrumentation 31

HowtoPerformaCalibration 31

CalibrationInputScreen 33

Units 34

Value 34

PerformingaNewCalibration 35

Test Setup 43

Test Setup 44

How to Fill Hydraulic Pistons 46

DeairingLiines 49

Filling the Triaxial Cell 51

Flushing the Triaxial Cell Water Lines 52

Specications 56

General Warnings 58

Warranty 58

Manufacturers Rights & Responsibilities 59