QUICK START GUIDE

2

Unpacking

Initial inspection should include checking for physical dam-

age during shipping and obvious external damage to the

product.

Package contents are defined by your packing list. Each

Order is configured according to customer specifications.

In your inspection, make certain that the contents of your

shipment match the documentation provided by your pack-

ing list.

Place unit on a flat, smooth surface and use leveling feet

(supplied) and a bubble level to ensure that the unit is level

side-to-side and back-to-front.

Installation and Equipment Setup

Electrical Connections

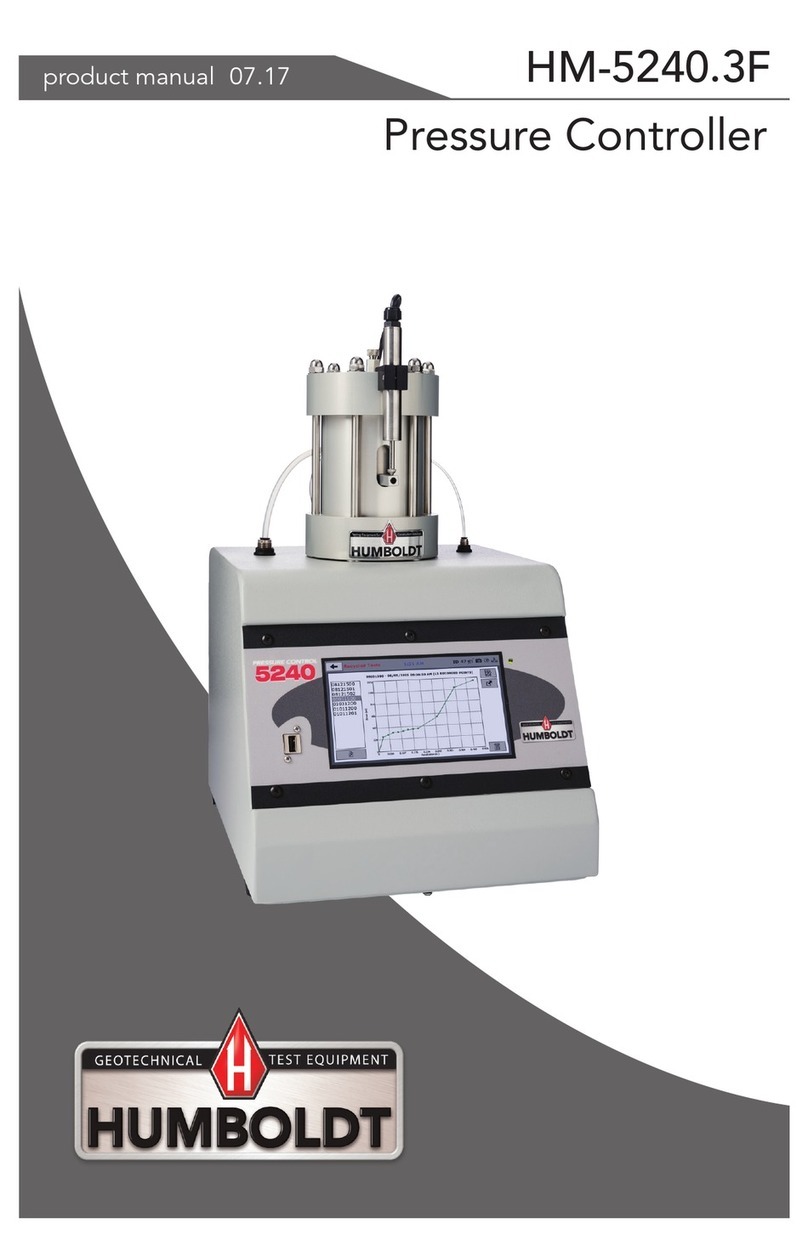

The HM-5250 is equipped with an internal digital switching

power supply, which allows it to be used with most power

configurations throughout the world. The unit is supplied

with an IEC electrical cord with a standard 110V plug.

The HM-5250 arrives ready for operation. Attach the sup-

plied IEC electrical cord to the machine and plug into a

standard wall receptacle for use in the United States. For

locations other than the U.S., replace the supplied electrical

cord with an IEC cord that has the correct plug for your ap-

plication. The supplied cord can also be used by cutting the

standard plug from the cord and attaching the correct plug.

Power Switch

The Power Switch is located above the electrical cord inlet.

The Fuse Compartment is located between the electrical

cord inlet and the Power Switch. The HM-5250 uses a 8.5

amp fuse. To begin operation, attach the supplied electrical

cord, plug it in and press the Power Switch.

Fig. 1 Power Switch

Fuse Compartment