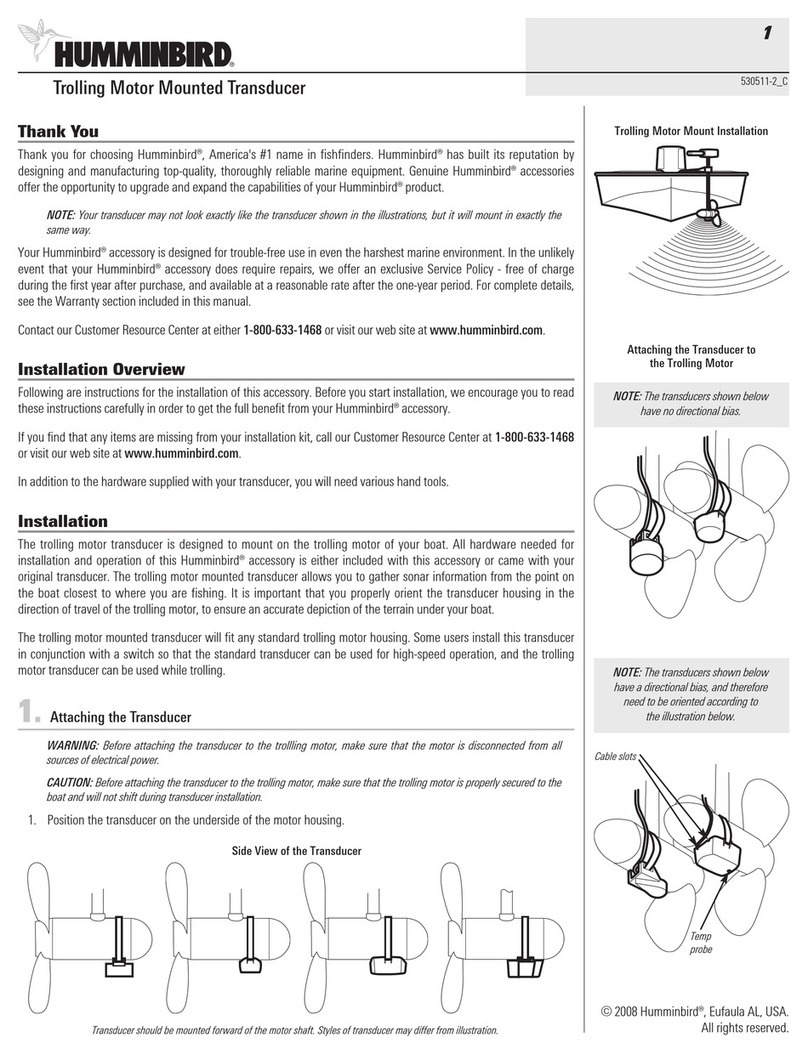

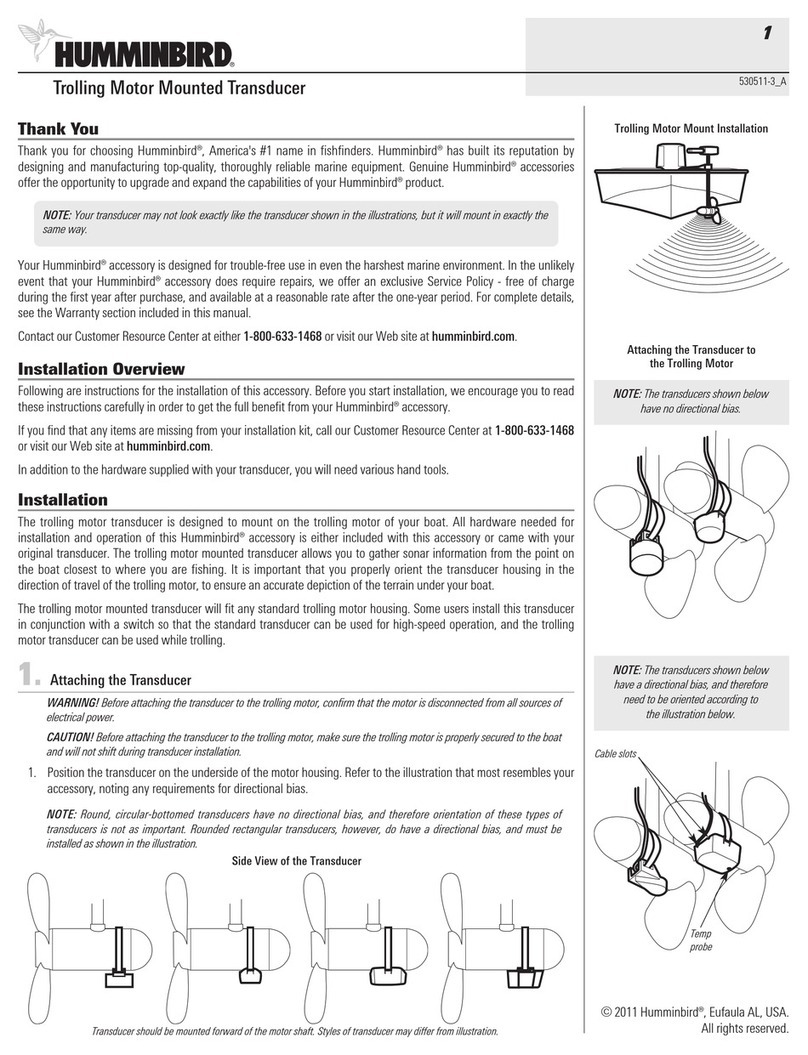

side of the transducer so the cable will not be damaged by the

rotating transducer.

Cable clamps are provided to secure the cable to the transom,

and use the same type of screws as the escutcheon plate.

Inside the boat, there is often a channel or conduit which is

used for other wiring, which can be used to route the transducer

cable forward. Avoid routing the cable in areas where it may

be damaged or interfere with normal boating operations.

The transducer cable should not be cut or shortened, and

care should be used not to damage the cable insulation. If

excess cable needs to be gathered at one location, dress the

routing of cable from both directions so that a single loop is left

extending from the storage location. Doubling the cable up from

this point, form the cable into a coil. Storing excess cable with

this method can reduce electronic interference.

Also, be sure to route the cable as far as practical from the

antenna cable of VHF radios to reduce the possibility of

interference.

This accessory works with a number of Humminbird

depthsounder products. Some products may require

disassembly of the depthsounder mounting bracket in order to

connect the cable. Refer to the operations manual for your

depthsounder.

If you find that the cable is too short for your application,

extension cables are available at a reasonable cost which can

extend the transducer cable up to 50'. Call Humminbird

Customer Support for more information.

Confirm the pivot angle has not changed.

MAINTENANCE

If your boat remains in the water for long periods of time,

algae and other marine growth can reduce the effectiveness of

the transducer. Periodically clean the face of the transducer

with liquid detergent.

If your boat remains out of the water for a long period of

time, it may take some time to wet the transducer when

returned to the water. Small air bubbles can cling to the

surface of the transducer and interfere with proper operation.

These bubbles will dissipate with time, or you may wipe the

face of the transducer with your fingers after the transducer is

in the water.

High Speed Transducer

4

pn530505-2 r11107E

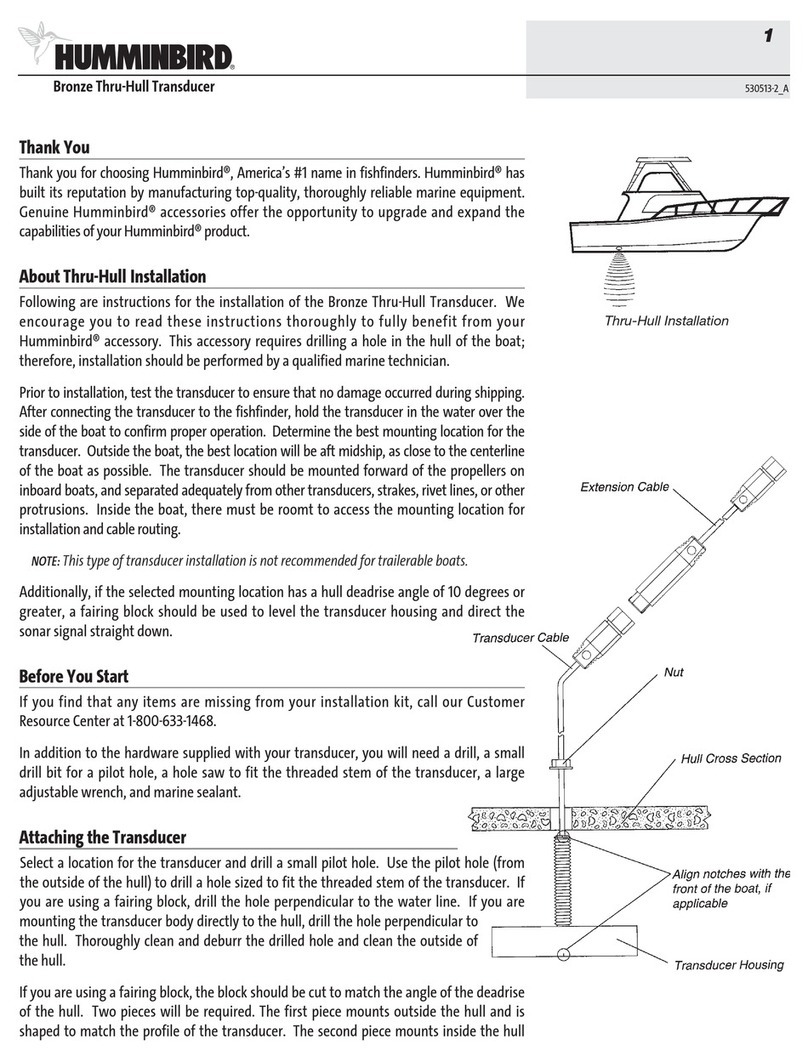

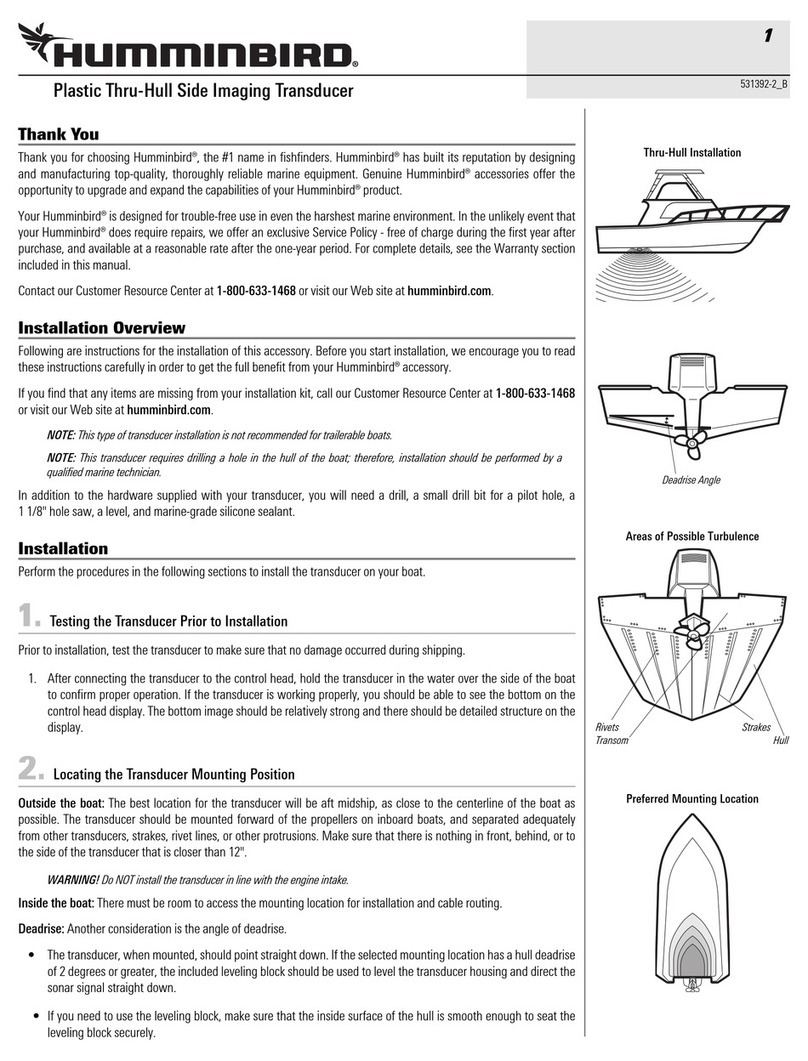

Place on bottom of hull

Align with transom.

DONOTLETDEADRISE

INTERSECTTHISLINE

PLACEEITHERCORNER

ONDEADRISEANGLE

TOP

Use5/32"drillbit

Drill Drill

PLACEEITHER CORNER

ONDEADRISE ANGLE

TOP

Use 5/32" drill bit

DrillDrill

Level

15", 40cm

from prop(s).

PLACE EITHER ARROW

ON DEADRISE ANGLE

TOP

Remove and use for

Transducer Installation

Use ⁵⁄₃₂" drill bit & drill

two holes for hull type

Drill ●

Drill ●

Drill ■

Drill ■

For use with bracket PN 404329-1

Cut and use for Fiberglass Hulls

Fiberglass

Fiberglass Fiberglass

Aluminum

AluminumAluminum

Transducer

Guide

¹⁄₂"

Transducer bottom

Hull

Cut and use for Aluminum Hulls

CUSTOMER RESOURCE CENTER

If you have any questions, call our Humminbird Customer

Resource Center Hotline:

1-334-687-0503

Throughout the U.S. and Canada, hours are Monday-

Friday, 8:15 a.m. to 5:00 p.m. Central time.

Or visit our web site: www.humminbird.com for

Product Support and troubleshooting guides.

If after reading “Troubleshooting” you determine your

unit needs factory service, please attach a description of

the problem and send it with the unit to the address

below.

If you are including a check, please attach it to the unit.

Humminbird

Service Department

108 Maple Lane

Eufaula, AL 36027

Further information on Humminbird products can be

found at:

www.humminbird.com

Storing excess Cable