Open tray dispensers/open sided basket dispensers

3 / 24

Table of contents

1 General information............................................................... 5

1.1 Product information......................................................... 5

1.2 Target group.................................................................... 5

1.3 Symbols.......................................................................... 5

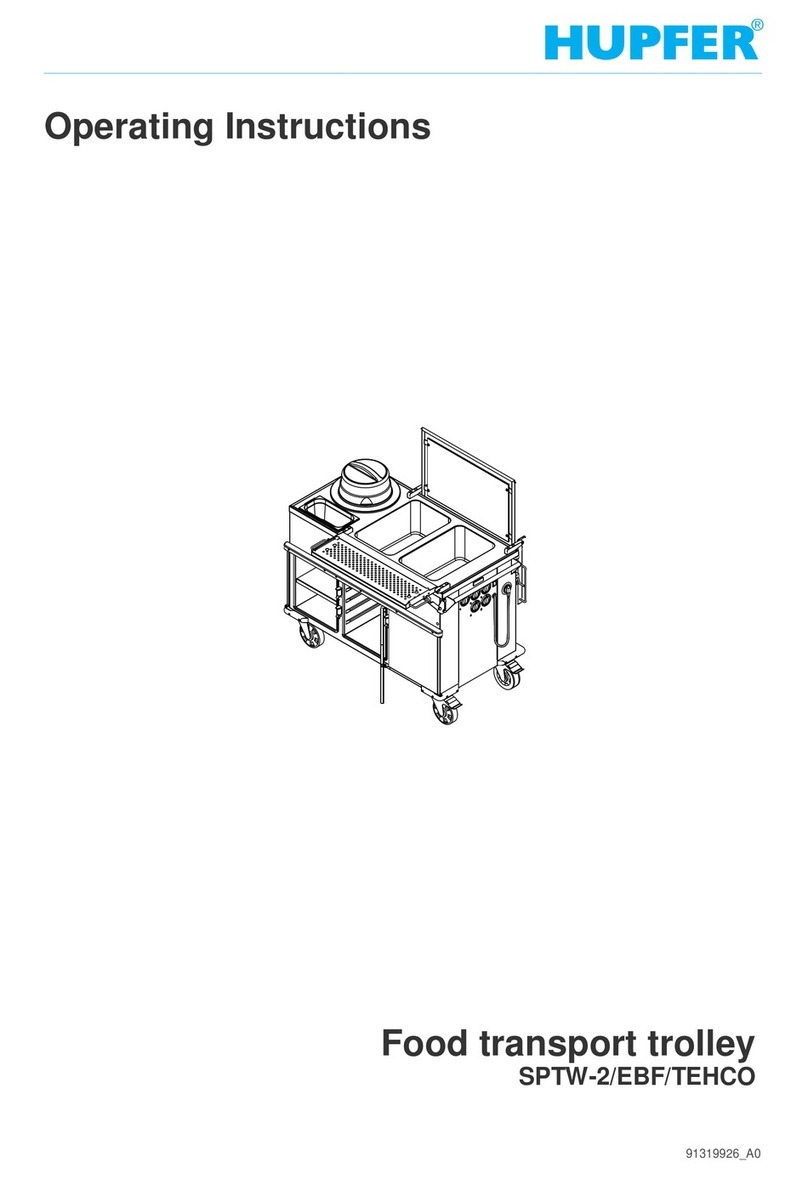

2 Product description............................................................... 6

2.1 Function.......................................................................... 6

2.2 Overview......................................................................... 7

2.3 Equipment features......................................................... 8

2.4 Equipment options.......................................................... 8

2.5 Technical data................................................................. 9

2.6 Rating plate..................................................................... 9

3 Safety information................................................................. 10

3.1 Intended use................................................................... 10

3.2 Improper use................................................................... 10

3.3 Safety instructions........................................................... 11

3.3.1 General information............................................... 11

3.3.2 Transport................................................................ 11

3.3.3 Assembly............................................................... 11

3.3.4 Operation and use................................................. 11

3.3.5 Cleaning................................................................. 12

3.3.6 Maintenance.......................................................... 12

3.3.7 Safety devices....................................................... 12

4 Transport................................................................................ 12

4.1 Delivery........................................................................... 12

4.2 In-house transport........................................................... 13

4.3 Lifting.............................................................................. 13

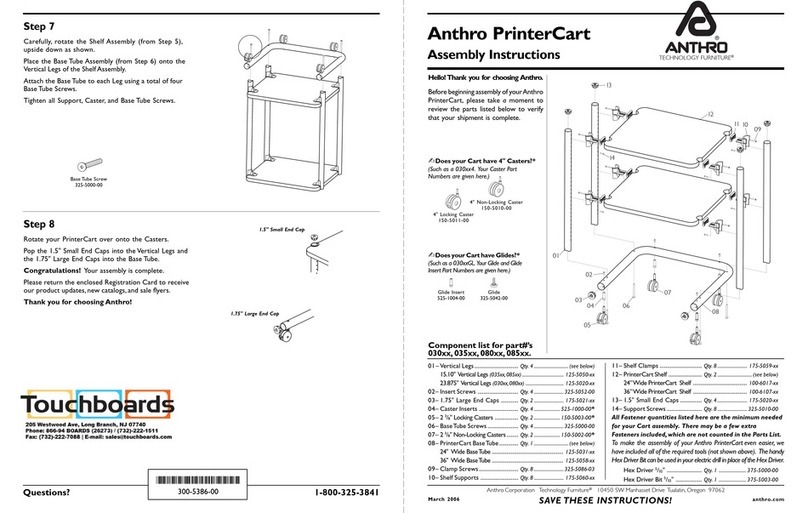

5 Assembly................................................................................ 13

6 Commissioning...................................................................... 14

7 Operation................................................................................ 17

7.1 Moving the cart............................................................... 18

7.2 Loading with items.......................................................... 19

7.3 Dispensing items............................................................. 19