Safety Instructions Chapter 2

Safety Instructions for Appliance Safety Page 9

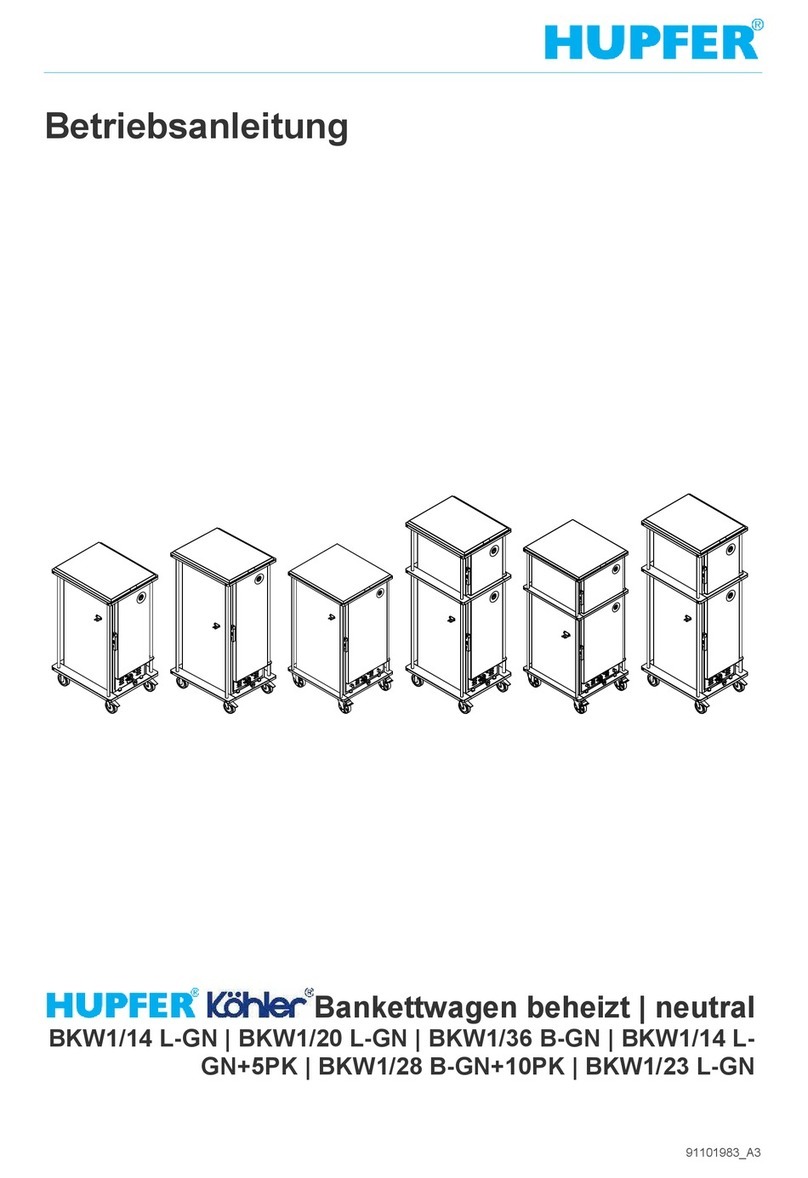

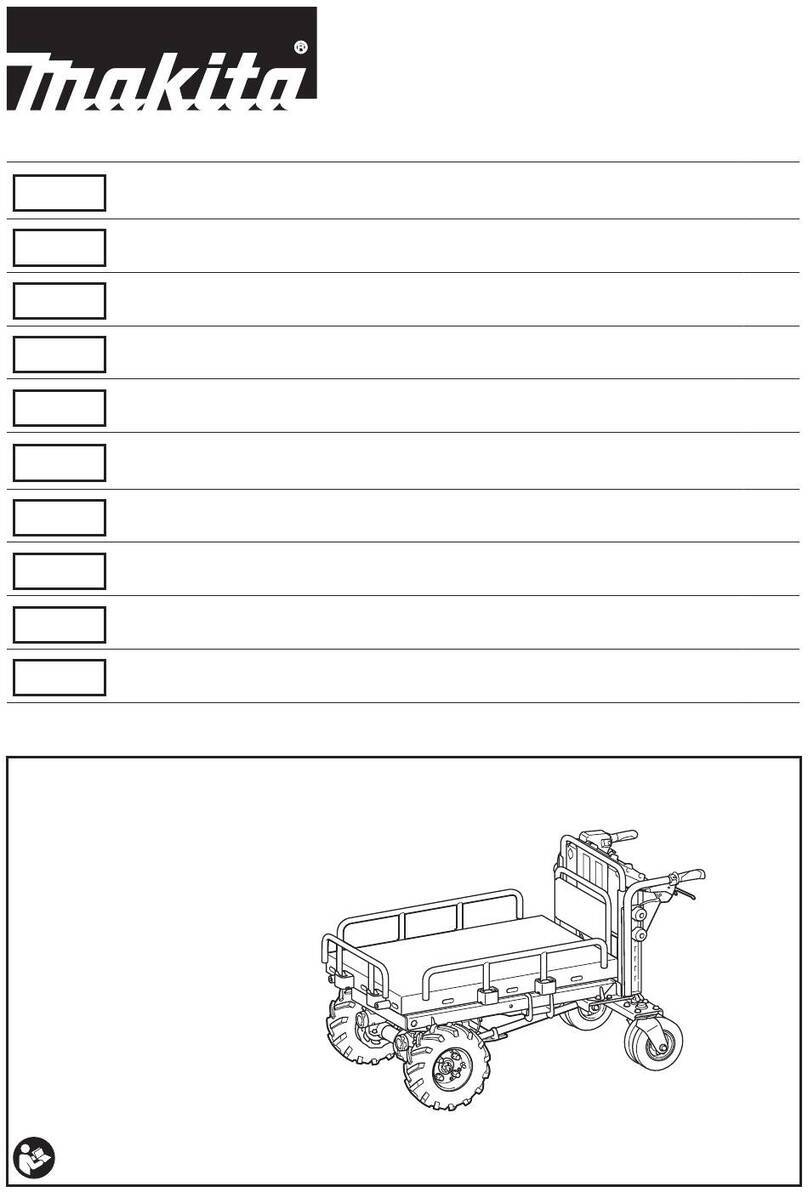

Food transport trolley

91319926_A0 SPTW-2/EBF/TEHCO

2.3 Safety Instructions for Appliance Safety

Safe operation of the appliance depends on appropriate and thorough use. Negligent handling of the appli-

ance can lead to danger to life and limb of the user and / or third parties as well as hazards to the appliance

itself and the other operator's property.

The following points are to be observed to ensure the appliance safety:

§The appliance may only be operated as intended, when it is in perfect condition with regards to tech-

nical standards, with awareness of safety and hazards and in accordance with the operating instruc-

tions.

§All the operating and actuating elements must be in a perfect and functionally reliable condition with

regards to technical standards.

§The appliance must be checked for external visible damage and defects whenever it is put into opera-

tion. In case of damages, inform immediately the competent bodies and switch off the food transport

trolley.

§Modifications or retrofits of the equipment are only permitted in consultation with the manufacturer

and on receipt of his written agreement.

§The appliances can only be operated under continuous supervision.

§Move the appliance only with the doors closed. Unless the doors are closed, they can open during

transport and cause in damages or lead to injuries.

§The appliance is provided exclusively for manual transport. Transport using any kind of devices is not

permitted. Risk of injury and damage.

§Release both total brakes before commencing transporting. Moving the appliance with the total

brakes locked can damage the chassis.

§Transport should only be undertaken over level floors. Moving the appliance over very uneven floors

and stair steps can damage the chassis.

§Do not stop the food transport trolley by applying the total brakes. The total brakes are designed to be

able to prevent the appliance from unintended moving. Do not stop the appliance on sloping floors.

Secure the appliance against rolling away by applying both total brakes when stopping it.

§When approaching walls and moving round obstacles always pay attention to persons in the way.

Risk of injury.

§When transporting the appliance, always grip the push bar with both hands. Never let go of the appli-

ance when moving it around.

§When transporting the appliance, do notmove it faster than a walking pace. Heavily laden appliances

are difficult to brake and steer. If necessary, ask for assistance when transporting the appliance.

§If the food transport trolley tips over due to outside influence or inattention, never catch it manually.

Risk of injury.

§In the case of off-site transport in a vehicle such as a lorry, the appliances should be secured proper-

ly. The total brakes are not sufficient as a transport securing method.

§Before transporting, switch off the appliance using the On/Off switch, pull out the mains plug and in-

sert it into the holder provided.

§Never pull the mains plug out of the socket by the connecting lead.

§Never move the appliance by pulling by the connecting lead.

§Never pull too tight or subject the connecting lead to tension, otherwise the mains plug may be dam-

aged.

§If the mains plug has come into contact with water it must be dried before inserting it into the socket.

Danger to life.

§Damaged mains plugs or the connecting lead are to be replaced by authorised specialists before the

appliance is used.

§Do not use any extension leads in wet and damp areas.