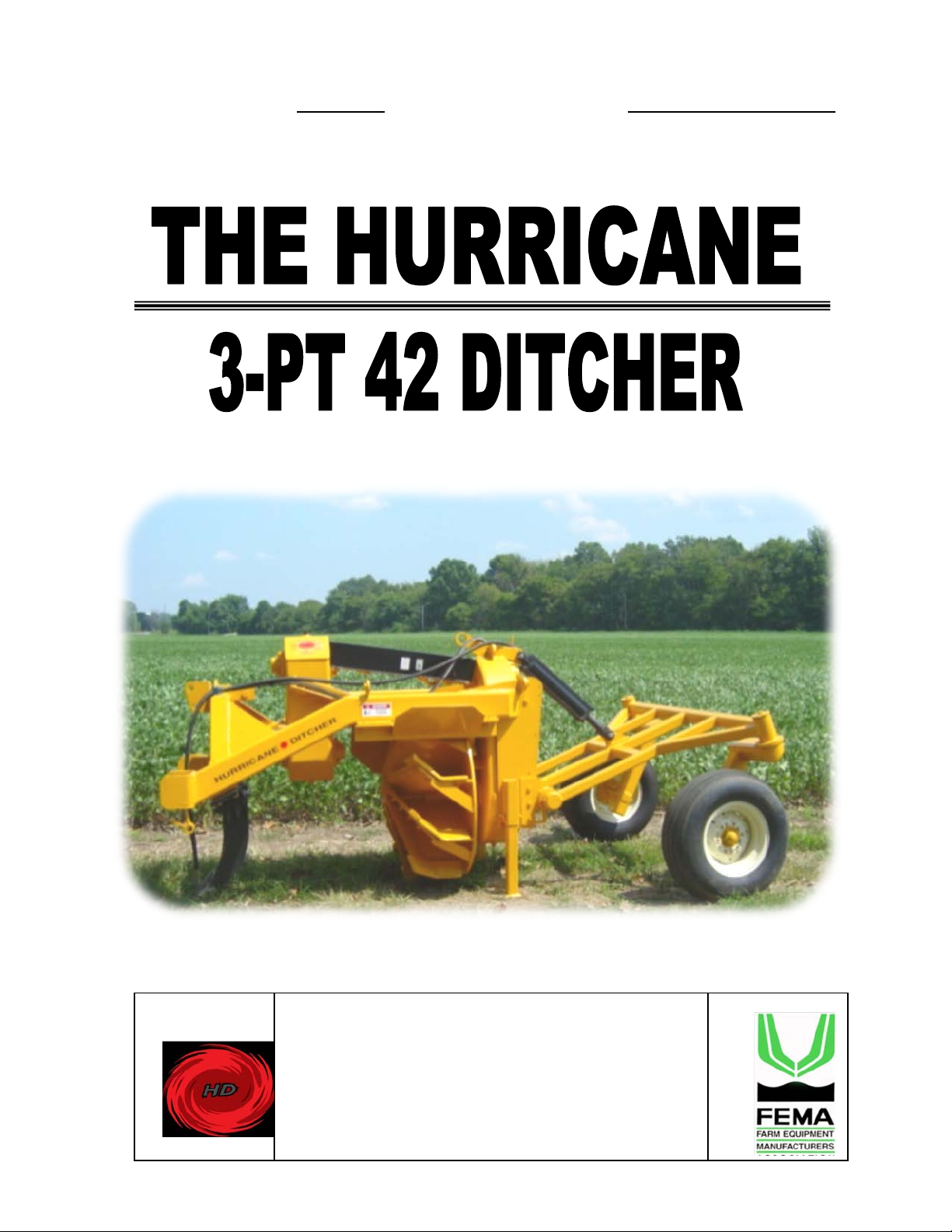

HURRICANE DITCHER CO., INC. 3-PT 42 DITCHER

17

WARNING! Do not use this machine with a PTO adaptor. The Agricultural Driveline

Manufacturers Association and The Association of Equipment Manufacturers discourage the use

of PTO adaptors due to serious safety and operational concerns.

UNHITCHING FROM TRACTOR

1) Park on level ground far enough from obstacles so that the terracing shield may be lowered. Lower

the parking stands to desired height and pin securely. The ripper tooth on the 3Pt42 is designed to

be the front support for the ditcher. Verify that the ripper tooth is intact and shear bolts have not

sheared. Gently lower, the ditcher until it is firmly supported on the ground.

WARNING! Always shut tractor engine off before unhooking PTO.

2) Pull the PTO safety slide lock (See item A below) back on the PTO and remove from tractor spline.

Gently lower PTO onto ripper tooth assembly for storage.

3) If your ditcher is equipped with an optional terracing shield, lower it, release the hydraulic pressure

from the hydraulic lines, and disconnect them from the tractor before pulling forward. If unhitching

you ditcher with the terracing shield attached, additional support may be required to keep ditcher

from tipping over. Do not risk personal injury or damage to ditcher from insufficient support.

4) If using a quick hitch, simply release the pins, lower the quick hitch, and slowly pull forward If not

using a quick hitch, release the clip pins, remove the, hitch pins, and slowly pull forward.

MAINTENANCE

If you are not going to use your machine for a period of time, paint the areas where the soil has

worn off the paint (for example: cutting edge, paddles).

After approximately every ten (10) hours of use, disconnect from tractor and check for the free

movement of driveline and proper chain tension (See page 9).

When the cutting edge wears out, unbolt it, and replace it with a new cutting edge.

When the impeller paddles wear, if slightly worn, weld with a hard surfacing rod on each paddle to

build them back up. NOTE: The factory installed hard surfacing is equal to a 60-65 Rockwell hardness.

If any component of your ditcher appears to be worn and needs replacement, please contact your

dealer for replacement parts.

LUBRICATION

Depending on the tail wheel assembly option chosen, the Model 3-PT 42 has seventeen or eighteen

(17-18) grease fittings. Refer to the Illustration below for the location of these fittings, and read carefully

the information on lubricating those areas. NOTE: Damage may occur due to lack of lubrication.

A – DAILY (before each use) – Grease the following with gun grease: #1-5

1 – The slip joint between PTO halves (remove from tractor, separate halves, apply gun grease

all the way around shaft, and reassemble).

2 – The two (2) universal joints at the ends of each PTO half.

3—The two (2) universal joints at the ends of the drive shaft.

4 – The two (2) fittings on the axle pivot assembly.

5—One (1) or two (2) fittings on tail wheel pivot.

Check Daily

6 – Check your tractor’s hydraulic oil reservoir level. When new, the ditcher’s cylinder will require

approximately ¾ gallon of oil. Use quality hydraulic oil specified by the tractor manufacturer.