2 – English

Workshop Manual

PW 345C, PW 350, PW 360

Contents

1 Introduction and safety regulations ............... 3

1.1 General ..........................................................................3

1.2 Revisions........................................................................3

1.3 Target group ...................................................................3

1.4 Safety instructions..........................................................3

1.4.1 General safety instructions ...................................3

1.4.2 Special safety instructions ....................................3

2 Repair instructions........................................... 5

2.1 Product overview............................................................5

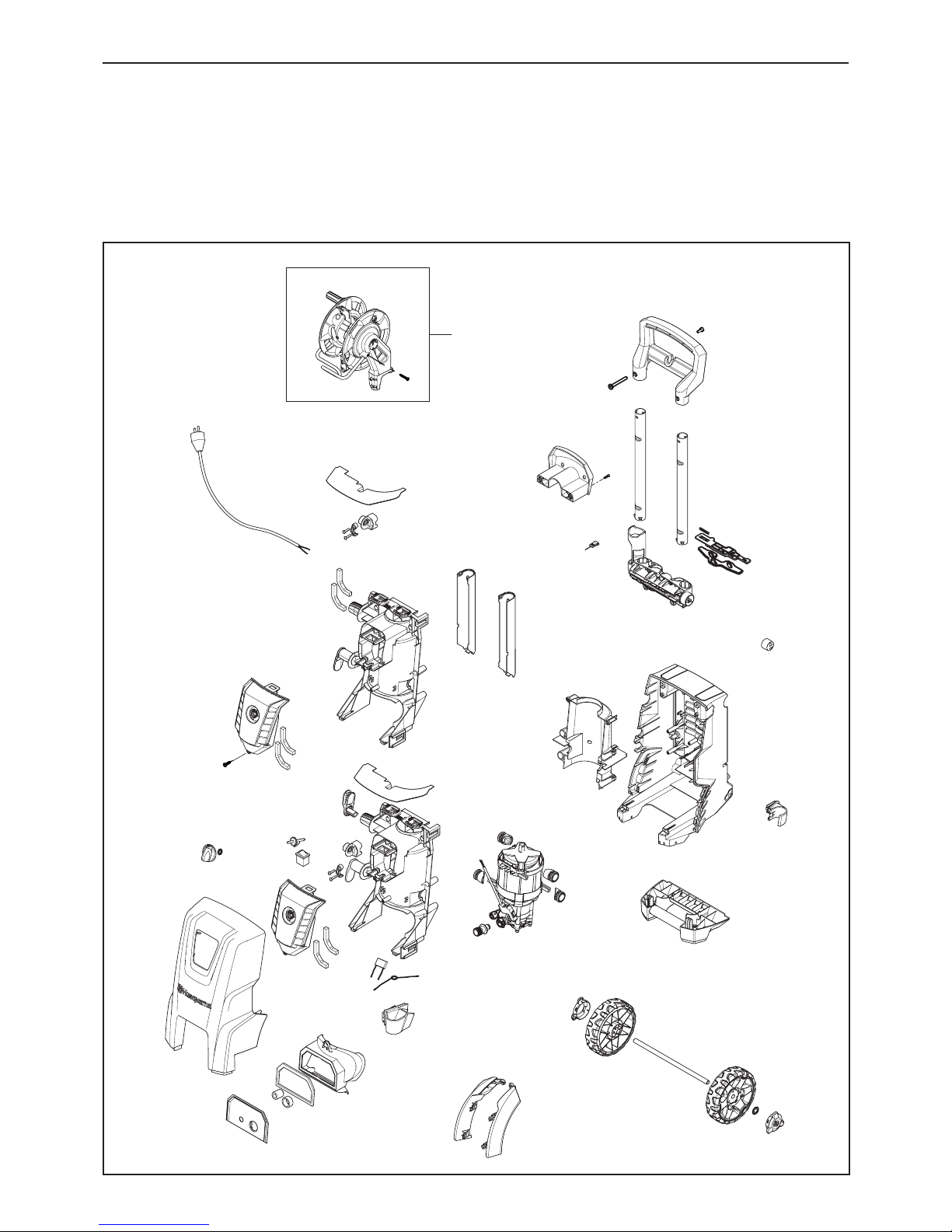

2.1.1 Cabinet parts overview, PW 345C,

PW 350, PW360 ...................................................5

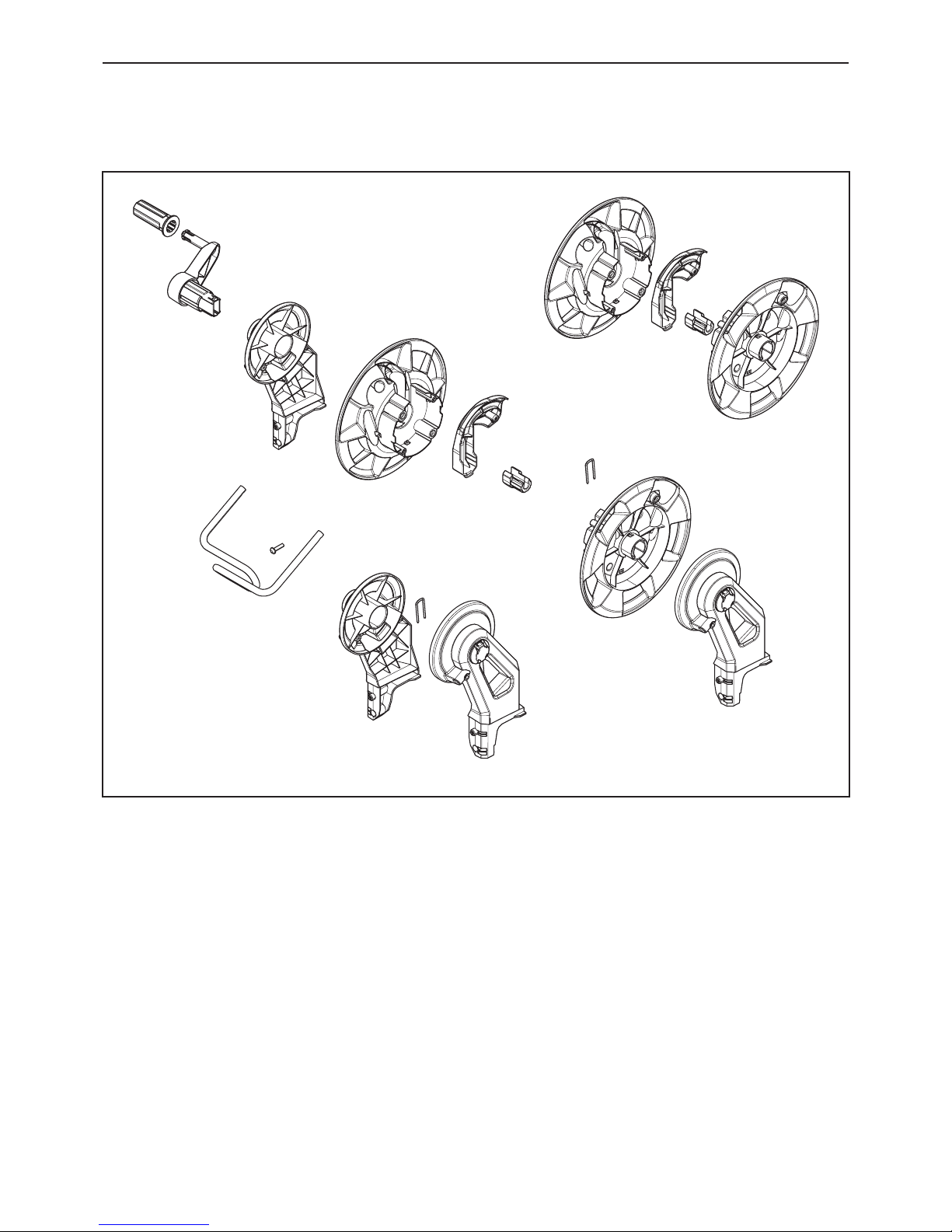

2.1.2 Hose reel overview ...............................................6

2.1.3 Motor/pump unit overview.....................................7

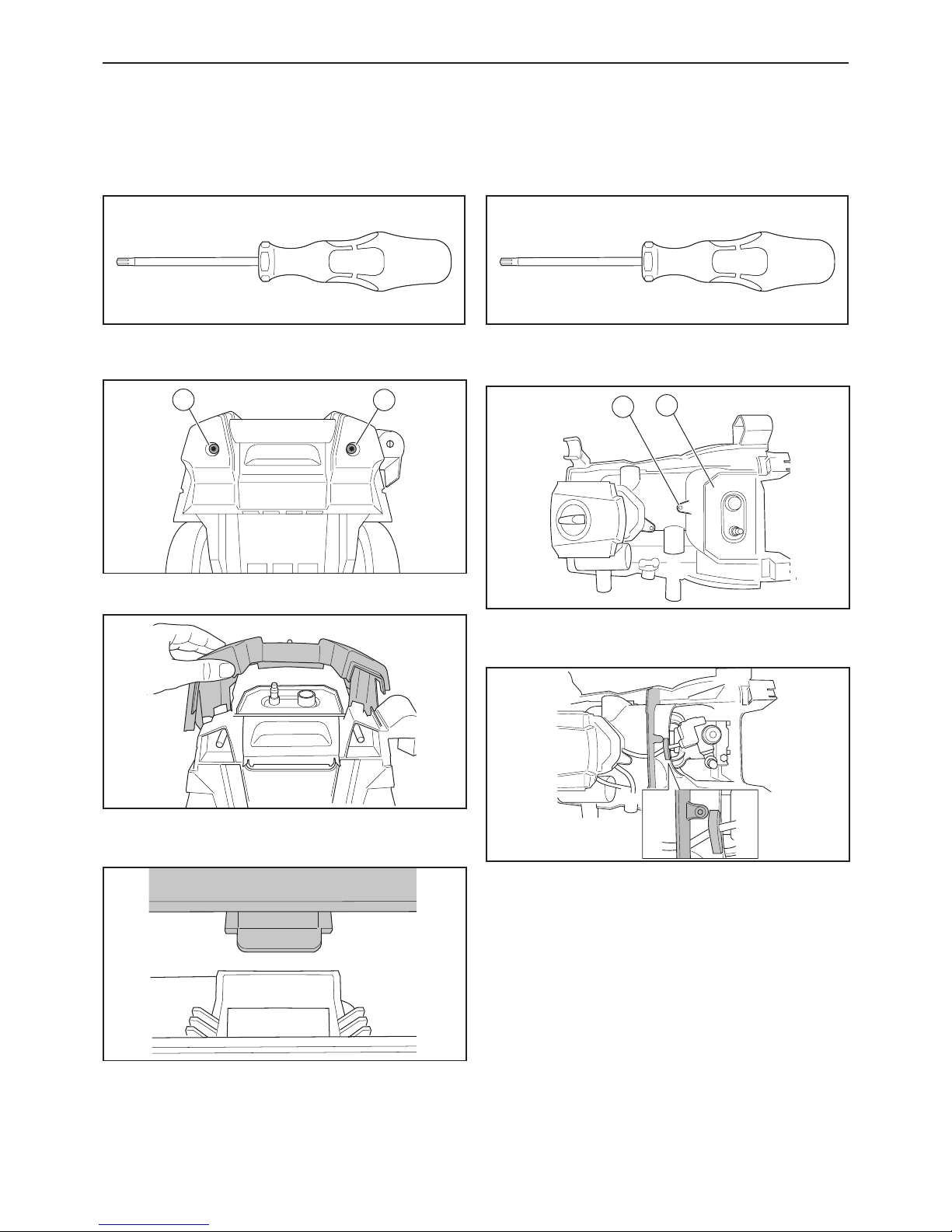

2.2 To disassemble/assemble the front cabinet ...................8

2.3 To disassemble/assemble the pump cover ....................8

2.4 To disassemble/assemble the start/stop system............9

2.5 To disassemble/assemble the switch box cover ............9

2.6 To disassemble/assemble the motor/pump unit,

PW 345C......................................................................10

2.7 To disassemble/assemble the switch ...........................10

2.8 To disassemble/assemble the motor/pump unit,

PW 350, PW 360.........................................................11

2.9 To disassemble/assemble the hose reel/internal

hose PW 350, PW 360.................................................11

2.10 To disassemble/assemble the hose reel,

PW 350, PW 360........................................................12

2.11 To disassemble/assemble the high pressure hose,

PW 350, PW 360........................................................12

2.12 To disassemble/assemble the hose reel,

PW 350, PW 360.......................................................13

2.13 To assemble the hose reel, PW 350, PW 360............13

2.14 To disassemble/assemble the easy start valve ..........14

2.15 To disassemble/assemble

the Non Return Valve (NRV) ......................................14

2.16 To disassembly/assemble the pump ..........................15

2.17 To measure the resistance of the electrical motor......16

3 Specications ................................................. 17

3.1 Technical data .............................................................17

4 Appendices and schedules ........................... 18

4.1 Operating supplies .......................................................18

4.1.1 Recommended oil types .....................................18

4.1.2 Recommended lubrication ..................................18

4.1.3 Recommended glue............................................18

4.1.4 Tools ...................................................................18

4.2 Motor pump function

<Machine stopped and hose emptied>, PW 345C only.....19

4.3 Motor pump function

<Machine operation>, PW 345C only ................................19

4.4 Motor pump function

<Machine standby>, PW 345C only...................................20

4.5 Motor pump function <Machine stopped and

hose emptied>, PW 350,PW 360 only .........................20

4.6 Motor pump function

<Machine operation>, PW 350, PW 360 only ....................21

4.7 Motor pump function

<Machine standby>, PW 350, PW 360 only.......................21

4.8 Wiring diagram, PW 345C ...........................................22

4.9 Circuit diagram , PW 345C...........................................23

4.10 Wiring diagram, PW 345C..........................................24

4.11 Circuit diagram, PW 345C..........................................25

4.12 Wiring diagram, PW 350, PW 360 .............................26

4.13 Circuit diagram, PW 350, PW 360 .............................27