Hussmann IMPACT Elite E2V User manual

Other Hussmann Merchandiser manuals

Hussmann

Hussmann HGM-3 BS User manual

Hussmann

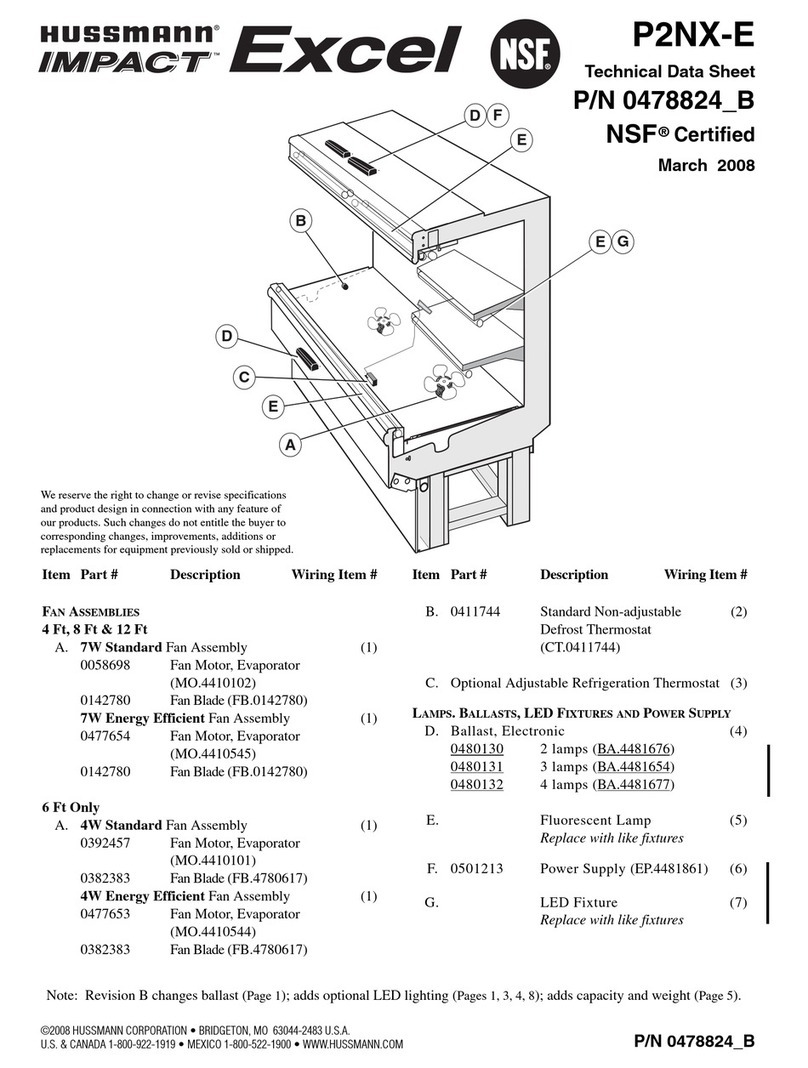

Hussmann P2NX-E Instruction Manual

Hussmann

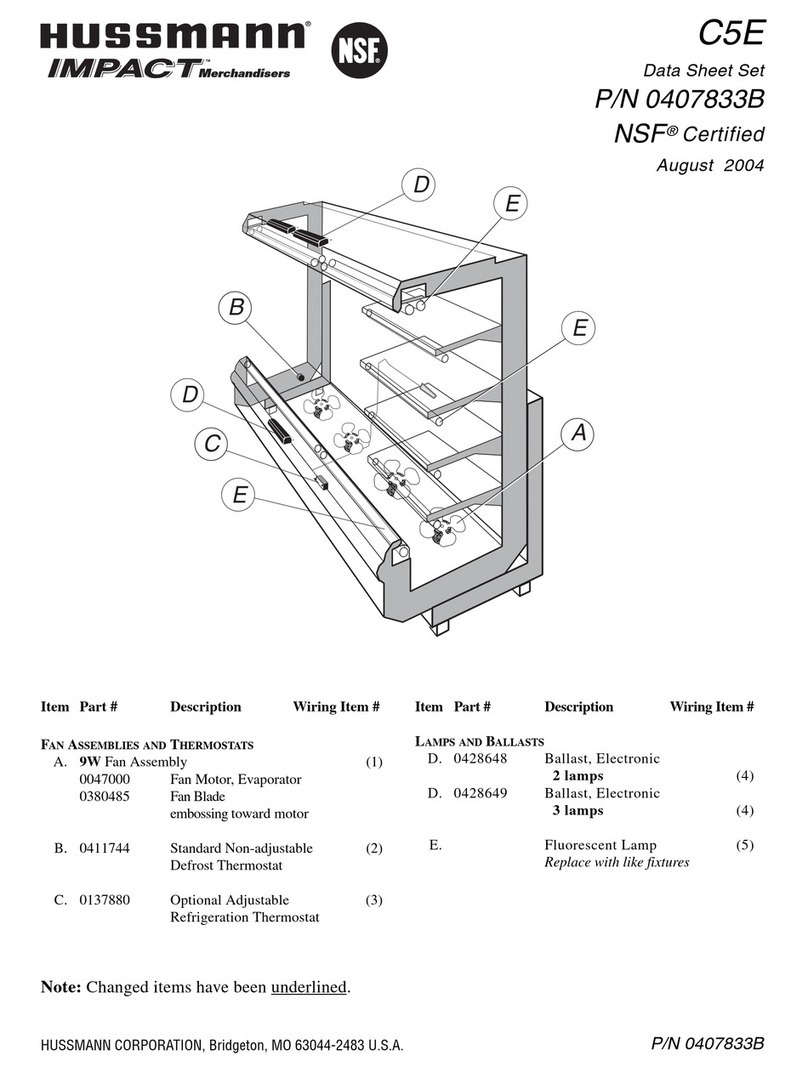

Hussmann impact C5E User manual

Hussmann

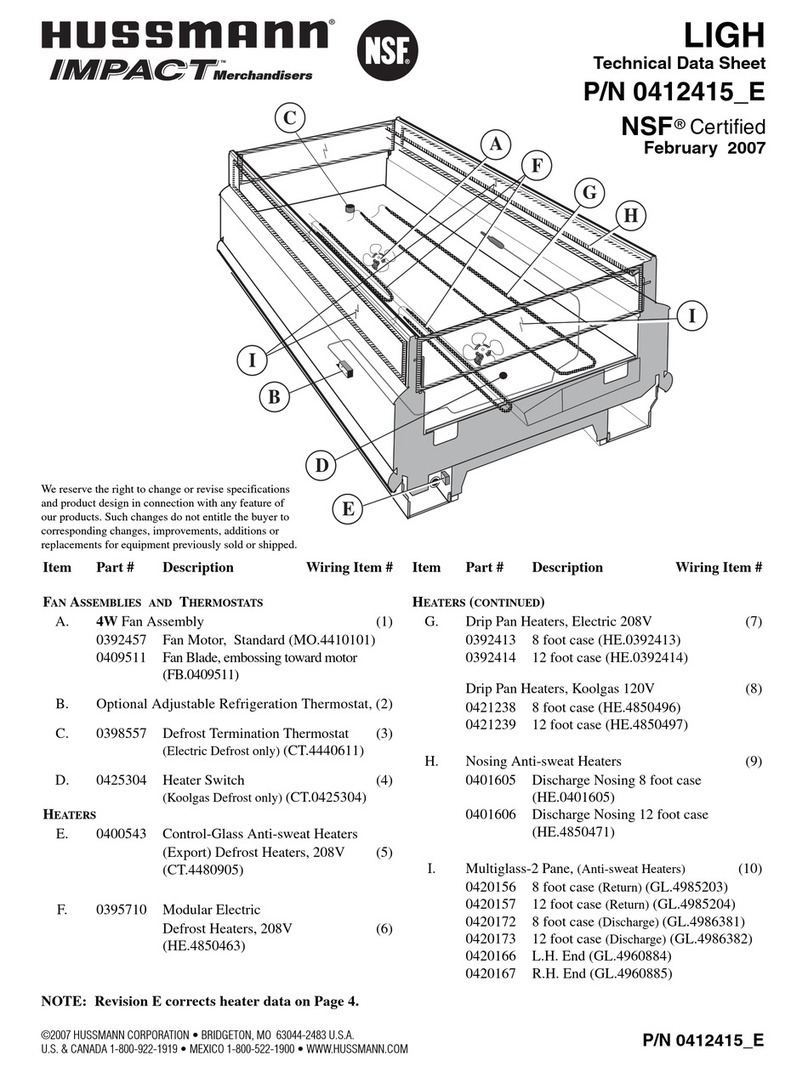

Hussmann IMPACT LIGH Instruction Manual

Hussmann

Hussmann micro SC SIM-4AA User manual

Hussmann

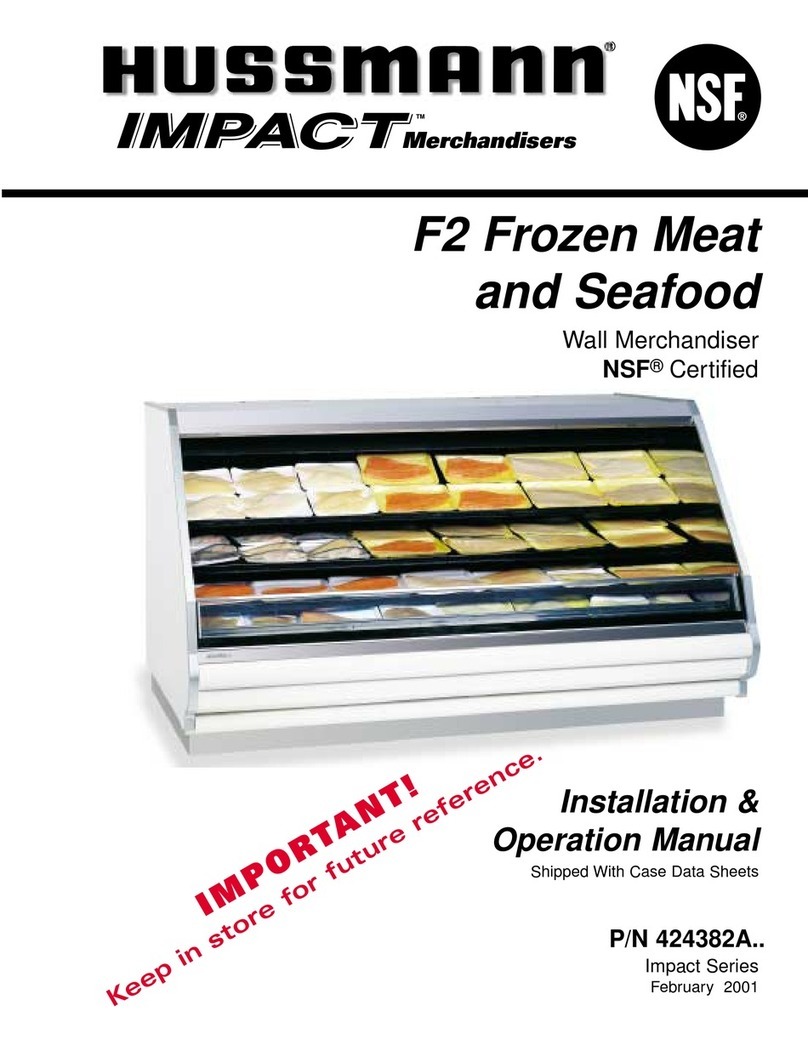

Hussmann Impact F2XLG User manual

Hussmann

Hussmann R3 Operating instructions

Hussmann

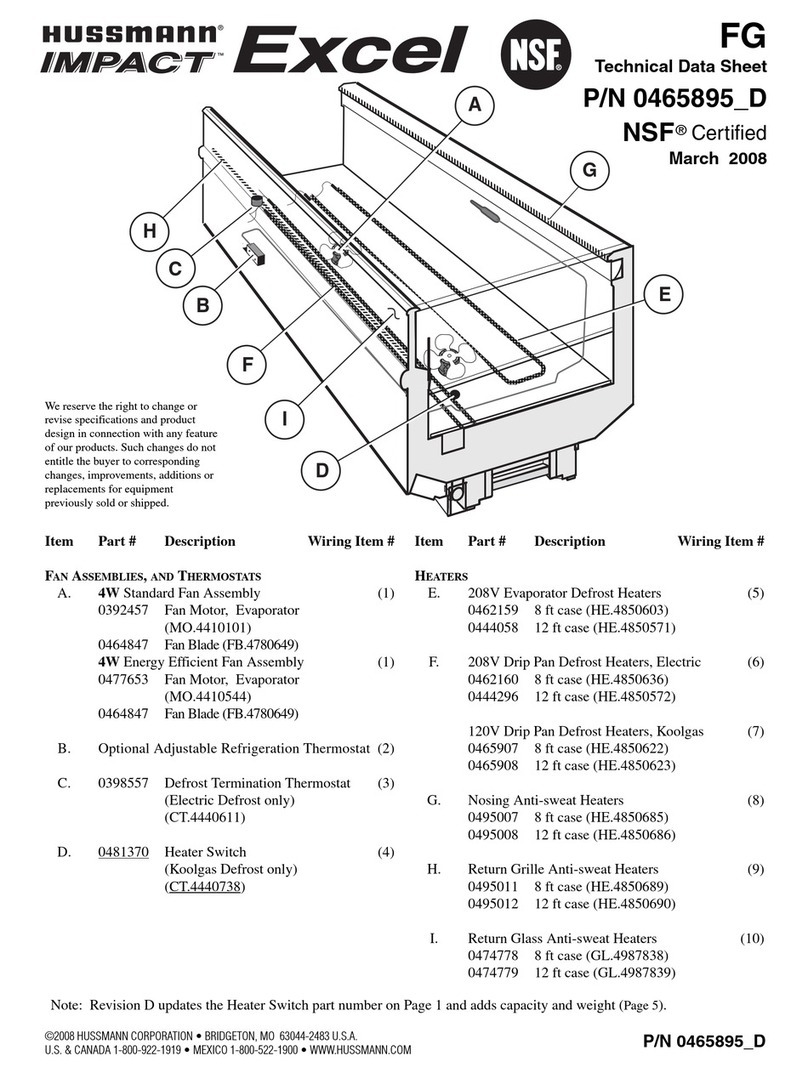

Hussmann FG Instruction Manual

Hussmann

Hussmann Impact Excel D5X-ULEP Manual

Hussmann

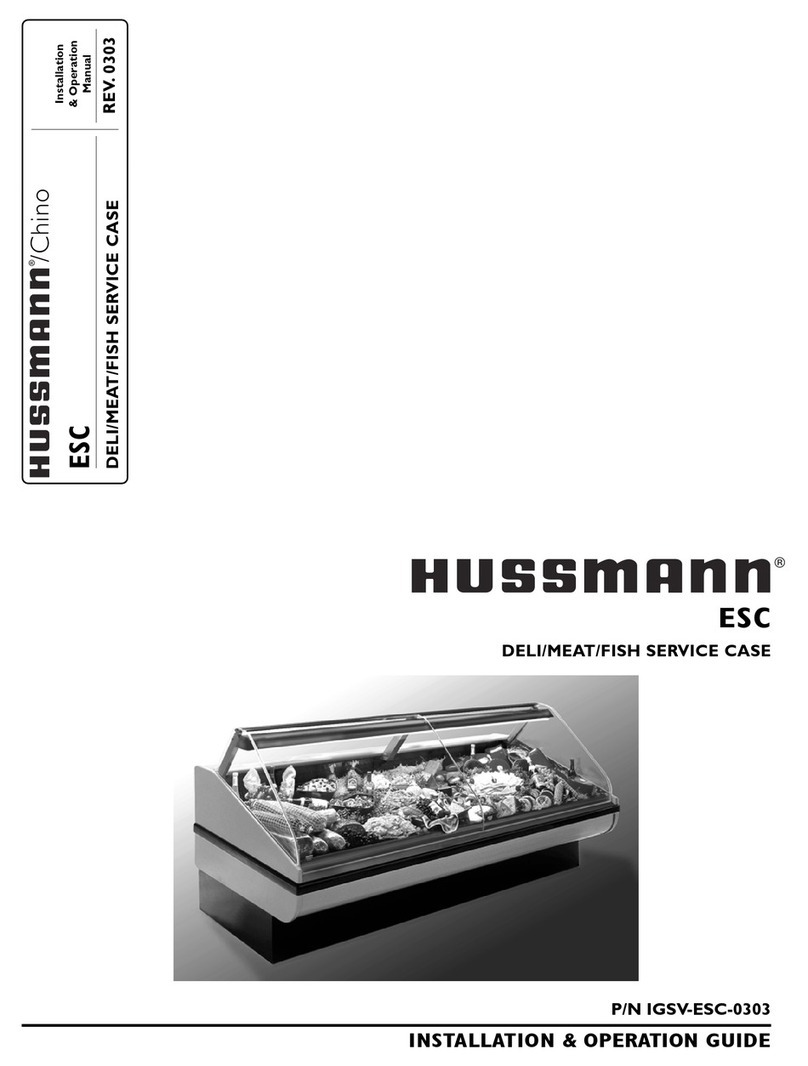

Hussmann ESC Operating instructions

Hussmann

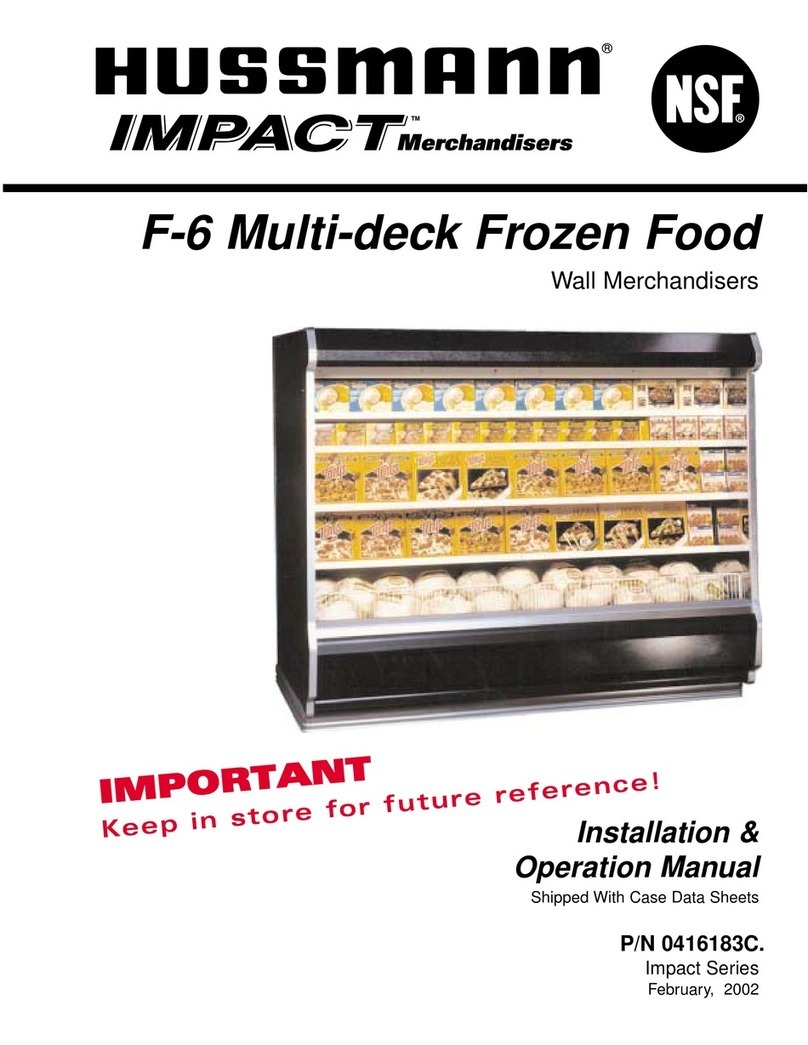

Hussmann Impact F6 User manual

Hussmann

Hussmann USL-2 Quick guide

Hussmann

Hussmann VBL User manual

Hussmann

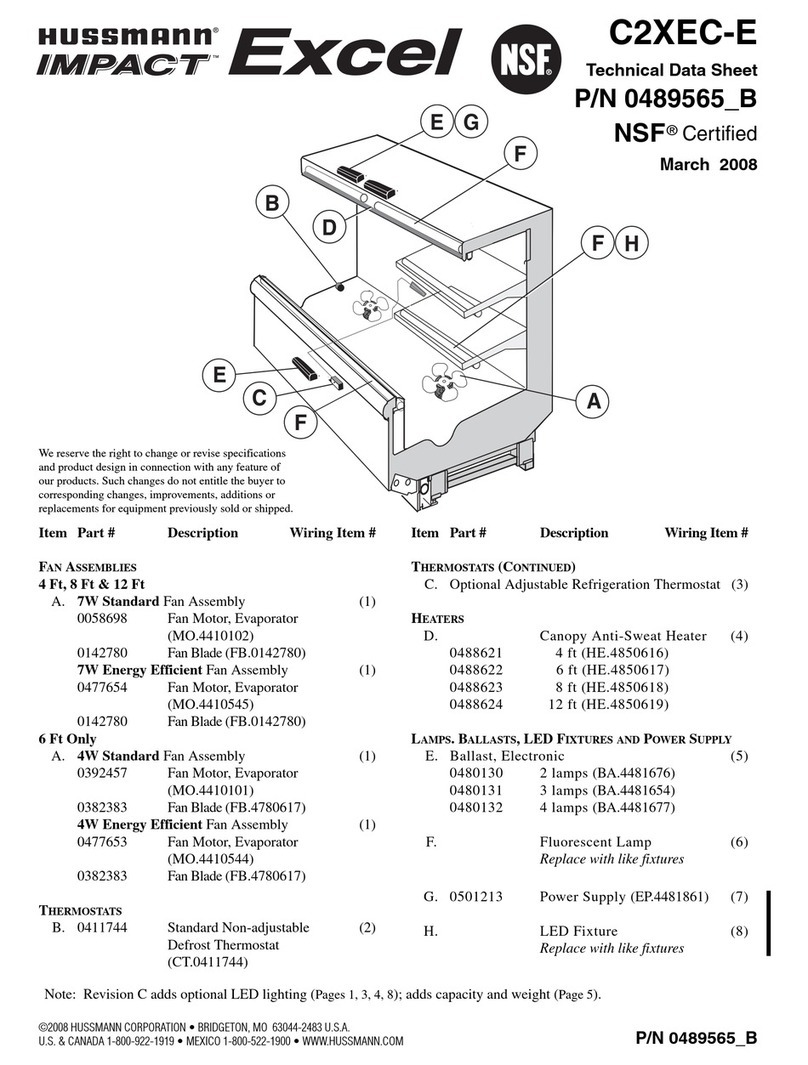

Hussmann C2XEC-E Instruction Manual

Hussmann

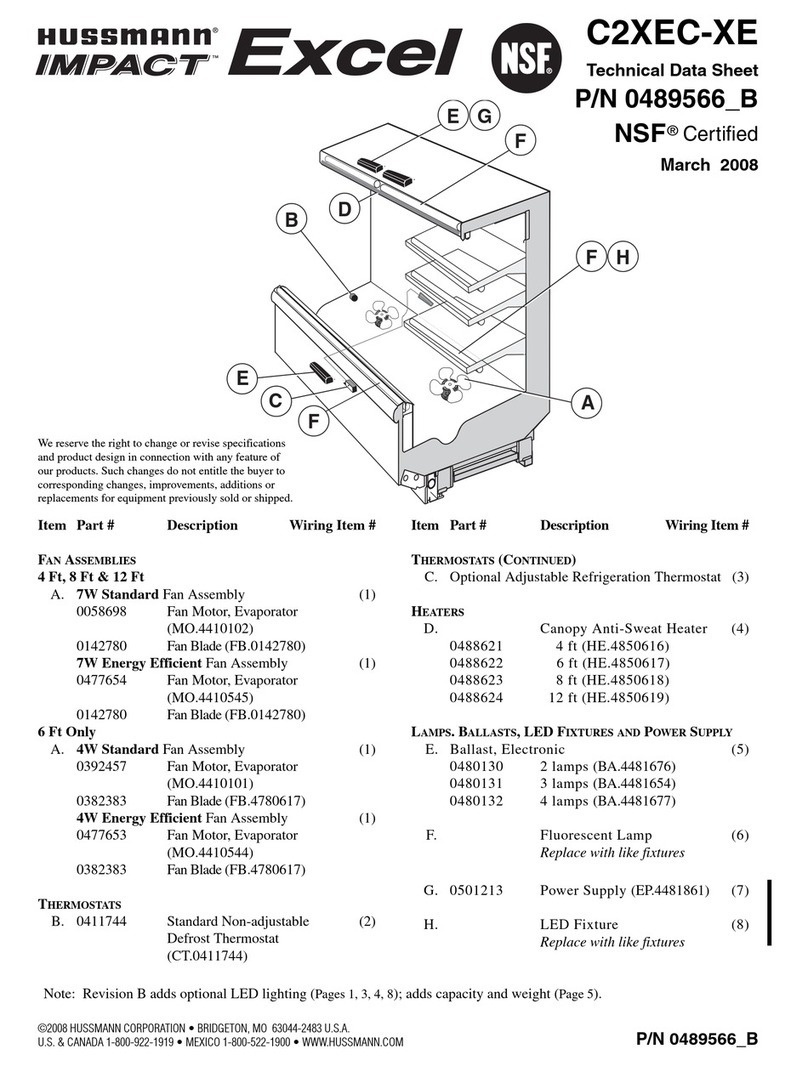

Hussmann C2XEC-XE Instruction Manual

Hussmann

Hussmann MWG User manual

Hussmann

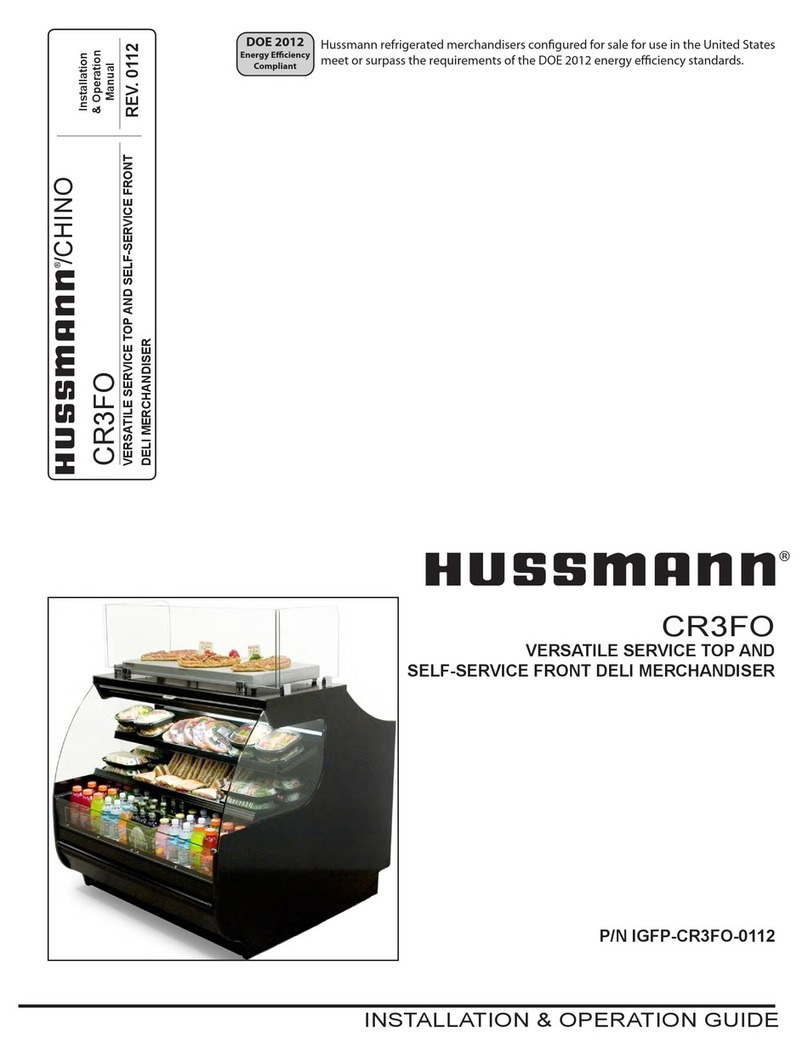

Hussmann Specialty ProductsCR3FO Original operating instructions

Hussmann

Hussmann VSG Operating instructions

Hussmann

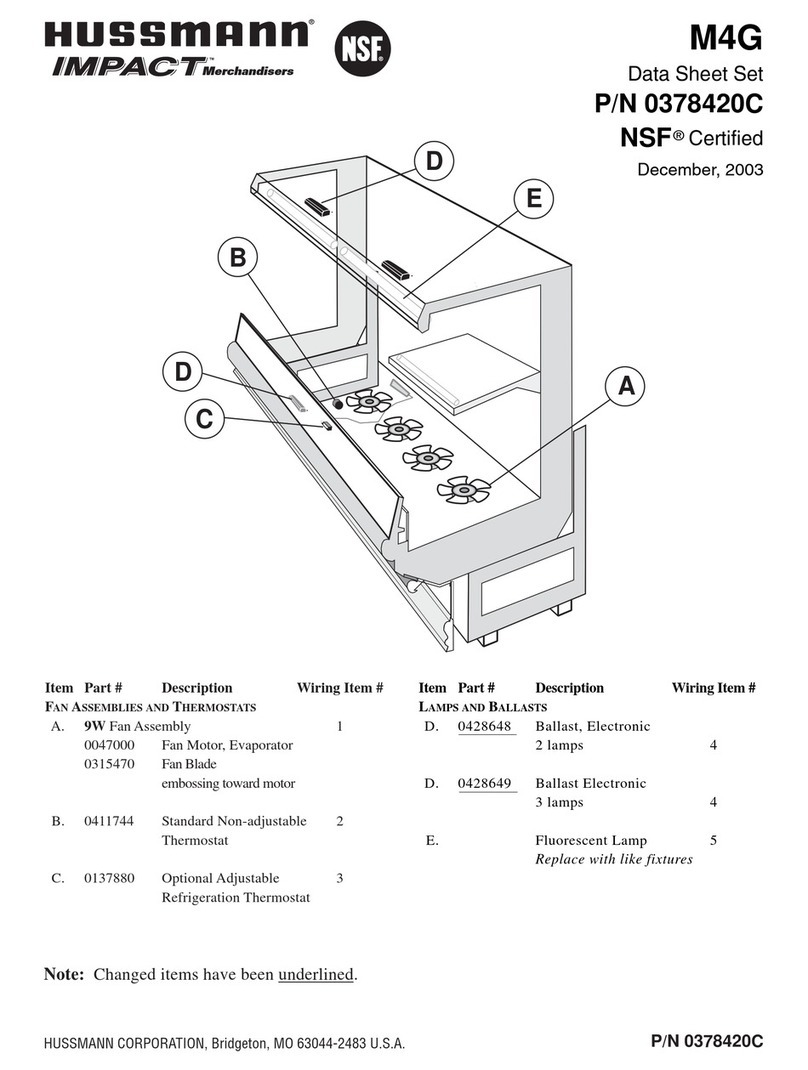

Hussmann IMPACT M4G User manual

Hussmann

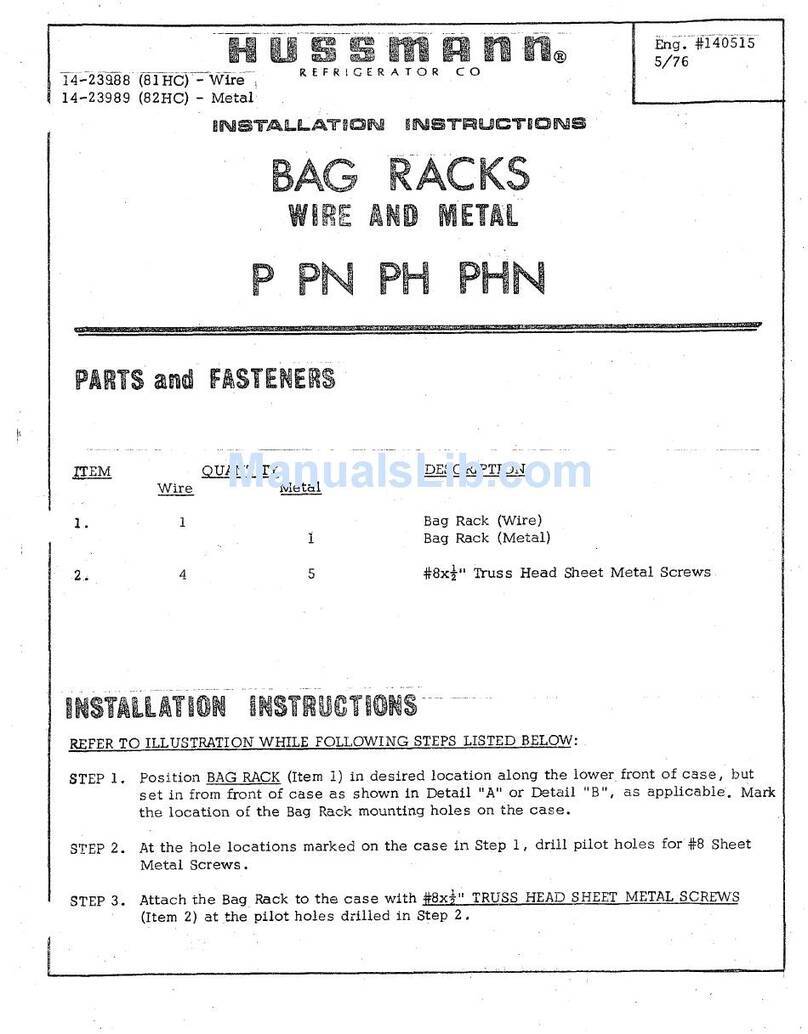

Hussmann Hussman P User manual

Popular Merchandiser manuals by other brands

FRIGOGLASS

FRIGOGLASS Flex 20 HC user manual

EPTA

EPTA COSTAN RHINO MULTI User instructions

CASCO

CASCO Nano Cube owner's manual

True

True GDIM-26 installation manual

Structural Concepts

Structural Concepts Oasis Mobile Series Installation & operating manual

Haussmann

Haussmann RL Installation & operation manual

Howard McCray

Howard McCray R-CDS32E-4 Specifications

EPTA

EPTA iarp Cool Emotions Delight Lite User instructions

VALERA

VALERA BC 85 datasheet

HL Display

HL Display 3eBin Assembly instructions

Dixie Narco

Dixie Narco DNCB 501E Technical manual

APW Wyott

APW Wyott Racer DMXD-30H Installation and operating instructions

Hoshizaki

Hoshizaki KD-90C Service manual

Summit

Summit SCR1006 instruction manual

Delfield

Delfield Shelleyspeed SPM-28E Specifications

EPTA

EPTA iarp Cool Emotions GLEE 40 User instructions

Kysor/Warren

Kysor/Warren GranBering KW TECHNICAL MANUAL & USER INSTRUCTIONS

Crane

Crane BevMAX Refresh 6 Media Operation guide