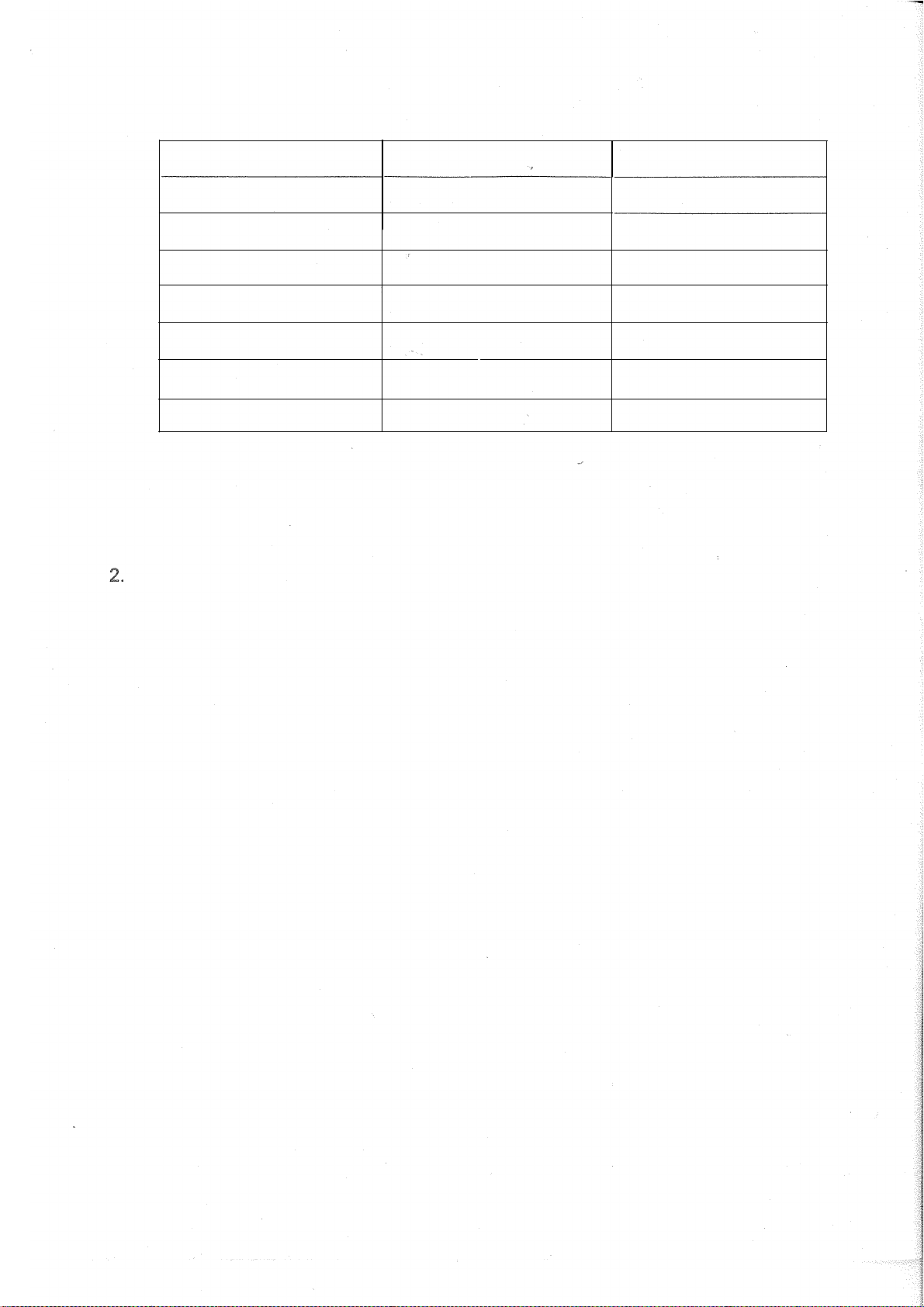

1 Main specification

NO.

1

2

3

4

5

6

7

MODEL

Max rolling width

Max rolling thickness

Rolling diameter

Rotate speed

Motor Power

Overall dimension

Weight

HU W1016X1 .5

40" (1010mm)

16gauge(1.5mm)

2"(50mm)

22rpm

0.75kw

1285x520x935( mm)

350kg

H Machinery general safety warnings

HU W-1300X1.5

50" (1280mm)

16gauge(1.5mm)

3"(75mm)

22rpm

0.75kw

1650x520x960(mm)

400kg

1. Misuse of this machine can cause serious injury. For safety, machine must be set up,

used and serviced properly.Read, understand and follow instructions in the operator's

and parts manual which was shipped with your machine.

Wear proper apparel. No loose clothing or jewelry which can get caught in moving

parts. Gloves and rubber soled footwear is recommended for best footing.

3. Do not overreach. Failure to maintain proper working position can cause you to fall into

the machine or cause your clothing to get caught -pulling you into the machine.

4. Keep guards in place and in proper werking order. Do not operate the machine with

guards removed.

5. Avoid dangerous werking environments. Do not use stationary machine tools in wet or

damp locations. Keep work areas clean and well lit.

6. Avoid accidental starts by being sure the start switch is "OFF" before plugging in the

machine.

7. Never leave the machine running while unattended. Machine shall be shut off

whenever it is not in operation.

8. Disconnect electrical power before servicing. Whenever changing accessories or

genera! maintenance is done on the machine, electrical power to the machine must be

disconnected before work is done.

9. Machinery must be anchored to the floor.

10. Use the right tool. Don't force a tool or attachment to do a job it was not designed for.

11. l( ep hands in sight and clear of all moving parts and rolling surfaces.

12. All visitors should be kept at a safe distance from the work area. Make workshop

completely safe by using padlocks, master switches, or by removing starter keys.

13. Know the

0

tool you are using -its application, limitations, and potential hazards.

14. Genera! Electrical Cautions :This machine should be grounded in accordance with the

National Electrical Code and local codes and ordinances. This work should be done by a

qualified electrician. The machine should be grounded to protect the user from electrical

shock.

2