1Scope of Application

The HUW1 Series Intelligent Universal Circuit Breaker (hereinafter referred to as “circuit breaker”) is suitable for

distribution networks with AC 50 Hz, rated working voltage of 690 V and rated current up to 6,300 A, and is mainly

used for power distribution, power feeding and power generation protection, so as to protect circuits and power

equipment from faults such as overload, undervoltage, overvoltage, current voltage imbalance, short circuit and

grounding fault. The rational operation of the power grid can be realized through load monitoring, regional interlock

and other functions. Furthermore, the circuit breaker can also be used to measure power grid parameters such as

current, voltage, power, frequency, electrical energy, demand and harmonics. It can also be directly used for overload,

undervoltage and short-circuit protection of motors and generators.

The core component of circuit breakers adopt intelligent controllers, which can realize accurate selective

protection, so as to avoid unnecessary blackout and enhance the reliability, continuity and safety of power supply.

These components can also be equipped with open communication interfaces to realize telemetering, telesignaling,

telecontrol and teleregulation, thus meeting the requirements of the control center and the automation system.

The circuit breaker series can be used as isolators without intelligent controllers and transformers.

The circuit breaker series can be compatible with top-in or bottom-in incoming lines, which is suitable for various

low-voltage power distribution fields such as power stations, factories and intelligent buildings, and can also be used

for infrequent starting of motors.

The derivative products of this series of circuit breakers, HUW1PVA and HUW1F, have passed the

ultra-high/-low temperature environment test and the "three prevention" related test, and are suitable for photovoltaic

and wind power generation systems with AC 50 Hz, rated voltage up to 690 V and rated current up to 3,200 A. They

are mainly used for power distribution, power feeding and power generation protection, so as to protect the lines and

power supply equipment from faults such as overload, undervoltage, overvoltage, current voltage imbalance, short

circuit and grounding fault.

The product complies with GB/T 14048.2 Low-voltage Switchgear and Controlgear — Part 2: Circuit Breakers.

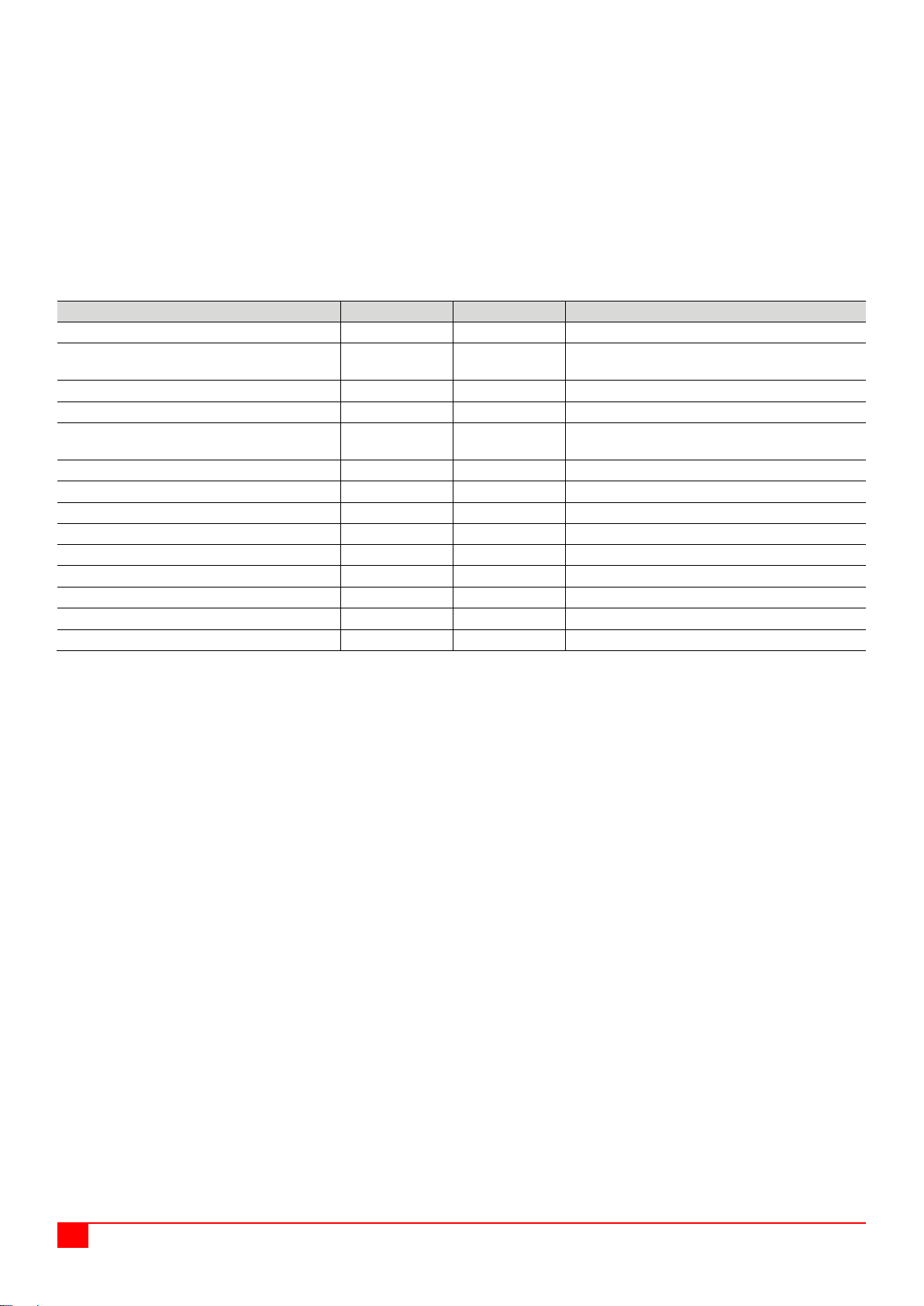

2Product Model Description and Classification

2.1 Product model description

2.2Classification

2.2.1 According to the installation mode

Fixed, drawer.

2.2.2 According to the number of poles

Three-pole, four-pole.

2.2.3 According to the operation mode

Electrical operation, manual operation (for overhaul and maintenance).

2.2.4 Release type

Intelligent controller, undervoltage instantaneous (or delay) release and shunt strip.

2.2.5 According to the intelligent controller

Type L (DIP), Type M (digital) and Type H (liquid crystal).

2.2.6 According to the wiring mode

Horizontal wiring, vertical wiring.

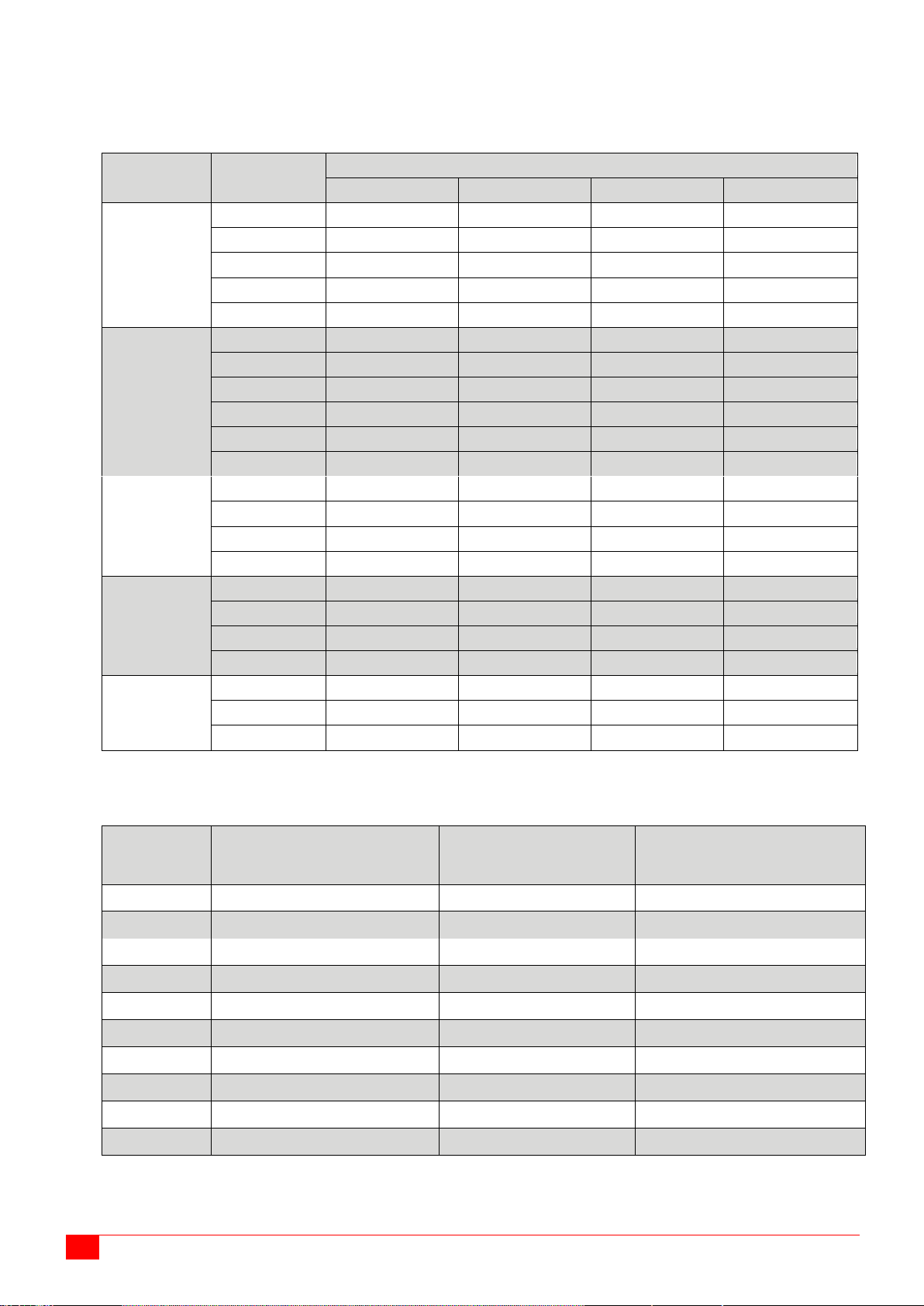

3Normal Working, Installation and Transportation Conditions

3.1 Normal working conditions

a) The ambient air temperature shall be -5°C to +40°C (-40°C to +70°C for HUW1F and HUW1PVA); and the

average temperature within 24 hours shall not exceed +35°C.

Note: If the upper limit exceeds +40°C or that the lower limit is lower than -5°C, the user shall consult with the

manufacturer.

b) The altitude of the installation location shall not exceed 2,000 meters.

Note: If the circuit breaker is used at an altitude above 2,000 meters, the user shall consult with the

manufacturer.

c) The relative atmospheric humidity does not exceed 50% when the ambient air temperature is +40°C, and a

higher relative humidity is allowed at a lower temperature. For example, when the average maximum relative