MP24.9731

09JUL09

SECTION II

625/625S SERIES LEVELING SYSTEMS

COMPONENT INSTALLATION

Vehicles with spring suspensions. The ground clearances listed in the Dimension Charts apply to vehicles with a

full load of fuel, water and equipment. If the vehicle is empty, typically 1 inch should be added to the listed dimensions. Also,

if the vehicle is new, the vehicle may settle down 3/4 of an inch or more in the first year or 10,000 miles.

CLEARANCE TO WORK UNDER THE VEHICLE WITH THE AIR BAGS DEFLATED.

SEVERAL INCHES WHEN THE AIR IS EXHAUSTED FROM THE AIR BAGS. MAKE SURE THERE IS ADEQUATE

VEHICLE IF THE VEHICLE IS SUPPORTED ON THE SUSPENSION AIR BAGS. THE VEHICLE WILL RAPIDLY DROP

DO NOT CRAWL UNDER A VEHICLE WITHOUT PROPERLY SUPPORTING THE FRAME OF THE

WARNING:

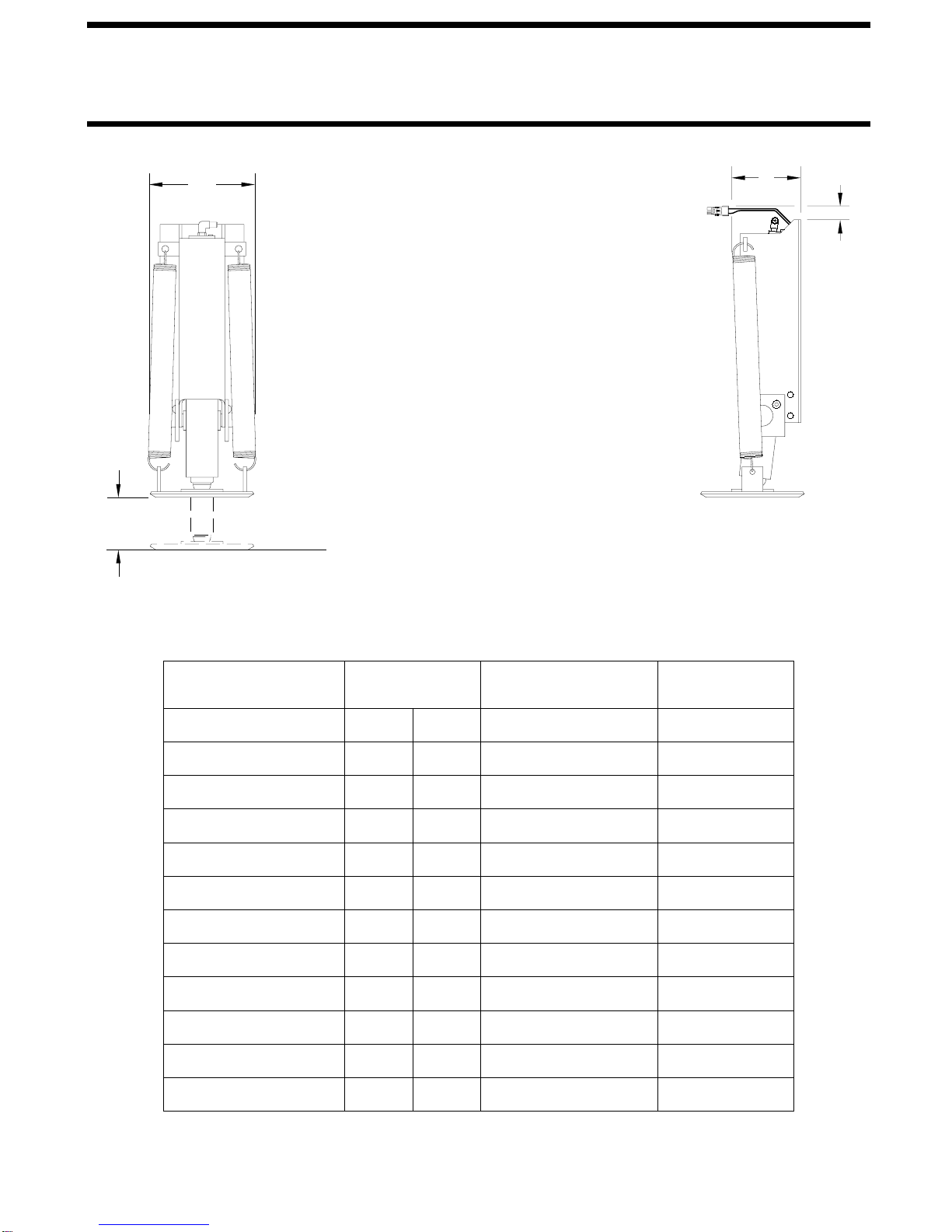

Vehicles with air suspensions. Typically, straight-acting jacks are used on vehicles with an air suspension. If the

vehicle is at normal ride height when mounting heights are set, you must remember the chassis will lower between 2 and 3

inches when the suspension air bags are emptied. Ground clearances listed in the Dimension Charts are typically figured with

the suspension air bags empty. If possible, measure the difference between the bottom of the frame and the ground with the

vehicle at normal ride height and with the air bags empty. Add this dimension to the suggested ground clearance for the jacks

listed in the dimension charts. Example: A 13 inch stroke jack is typically mounted with 7 to 9 inches of ground clearance. A

vehicle with an air suspension drops 3 inches from normal ride height when the suspension air bags are emptied. The typical

ground clearance for this installation should be 10 to 12 inches with the vehicle at normal ride height.

The following are some general rules to follow for a typical installation of leveling jacks on a vehicle:

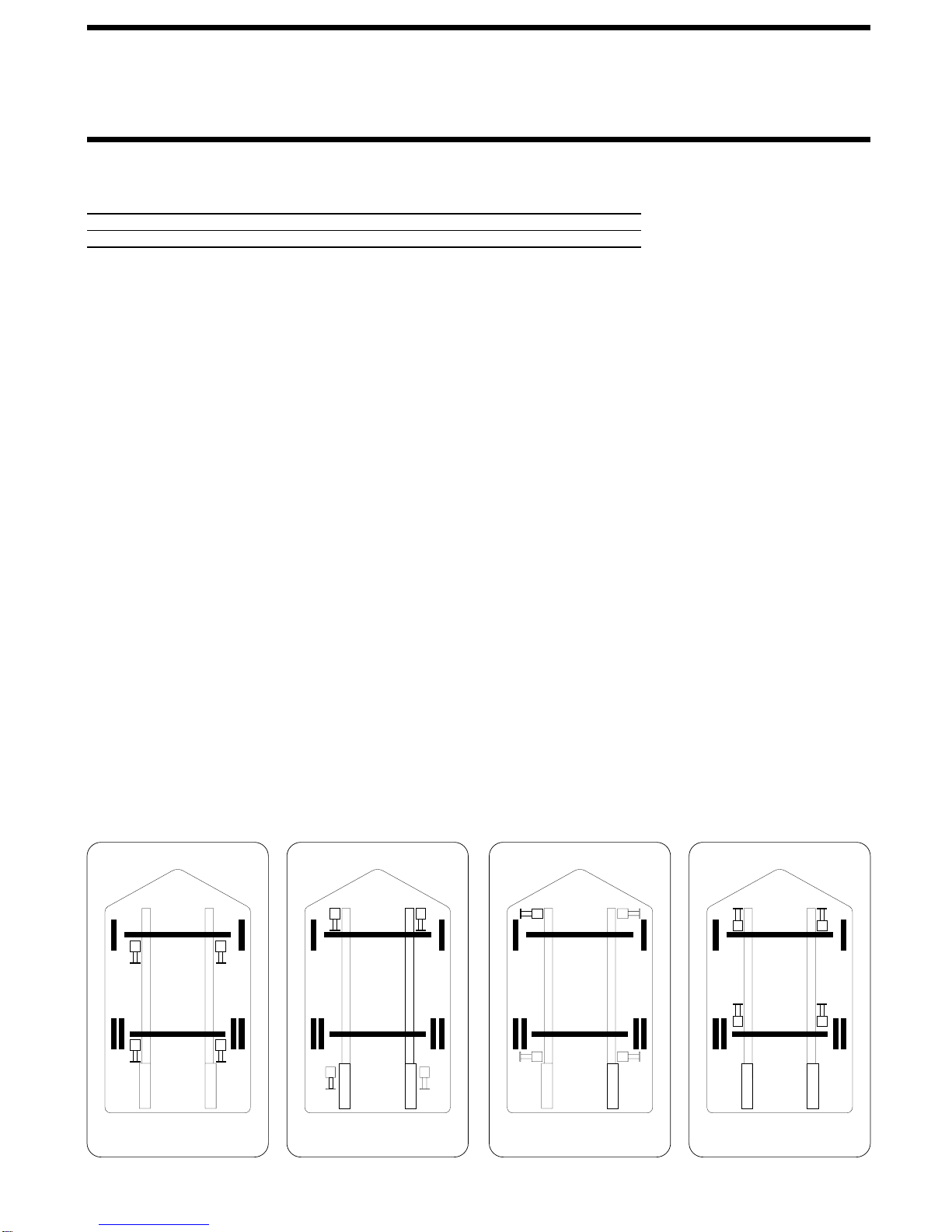

1.) The front and rear jacks should be mounted behind the front and rear axles as close to the axles as possible. Jacks are not

typically mounted in front of either the front or rear axles.

2.) The rear jacks are not typically mounted behind the end of the main frame rails on frame rail extensions.

3.) If the vehicle is equipped with a tag axle, the rear jacks are typically mounted between the drive axle and the tag axle.

4.) Front or rear jacks may be staggered several inches to accommodate vehicle equipment and compartments. If a cross tie is

required, staggering the jacks more than an inch or two may not be possible.

5.) Most mounting brackets and straight-acting jack pivot brackets are designed with specific mounting hole arrangements.

Some brackets are designed with a flange or finger that bolts to the bottom flange of the frame rail. When a mounting

bracket or pivot bracket has a specific mounting hole arrangement, use of all bolt holes, including the flange holes is

important. When mounting brackets or pivot brackets have multiple hole arrangements, the widest possible set of

holes should be used. Always bolt brackets as close to the top and bottom of the frame rail as the brackets allow.

6.) Jacks and/or mounting brackets must be mounted so they do not interfere with suspension components, springs, air bags,

linkages, etc. when retracted or extended.

7.) Front jacks and/or mounting brackets must be mounted so they do not interfere with the front tires when the tires are turned

from stop to stop. Remember as a vehicle moves up and down, the geometry of the suspension can change. Clearance with

the vehicle at rest may change as the vehicle moves up or down.

8.) Jacks should not be exposed to high temperatures such as exhaust components. Heat shields must be installed when

necessary. If heat shields are supplied with jacks or brackets, both sides should be installed. Aftermarket exhaust systems

may be installed at a later date.

9.) Normally, modification of the vehicle exhaust is not needed but if modification is needed, this should be done before the

installation of the leveling jacks.

Welding and drilling frame rails.Typically, HWH mounting brackets and jacks are designed with holes to allow a

bolt on installation. Welding to HWH supplied mounting brackets or a straight-acting jack pivot bracket is allowable but all

acceptable welding practices must be followed.

Before any welding is done on the frame rail, the chassis manufacturer

must be contacted for authorization and procedures.

Refer to WELDING in PART II JACK INSTALLATION for general

welding information. This section contains basic welding information including procedures to follow for several different

frame manufactures.

This information may not be complete and may change from time to time so it is important to

contact the frame manufacturer for current, specific welding information and procedures.

When drilling holes,

do not

drill in the radius of the frame rail,

do not

drill closer than one bolt diameter to the edge of the frame rail flange and

do not

drill next to an existing hole. Again, one bolt diameter distance should be maintained.

As with welding, contact the

frame manufacturer for specific drilling information and procedures.

WHEN DRILLING OR WELDING, ALWAYS

CHECK BEHIND THE OBJECT YOU ARE WELDING OR DRILLING ON FOR OBSTRUCTIONS OR EQUIPMENT SUCH

AS WIRING, HOSES, BATTERIES OR HOLDING / FUEL TANKS. THESE OBJECTS MUST BE PROTECTED FROM

WELDING HEAT OR DRILLING.