MP34.0218

17JUN09

GENERAL INSTRUCTIONS

PREPARATION FOR TRAVEL

If parking on soft ground or asphalt paving, a wood block or

pad should be placed under each jack.

Any time a hydraulic leveling process is interrupted, retract

the jacks according to the JACK RETRACTION Section and

then restart the leveling process.

If the jacks cannot be retracted according to the JACK

RETRACTION Section, retract the jacks according to the

MANUAL JACK RETRACTION Section. The system

should then be checked.

EXTENDED CAN CAUSE SEVERE DAMAGE TO THE

MOVING THE VEHICLE WITH THE LEVELING JACKS

VEHICLE IS EQUIPPED WITH STRAIGHT-ACTING JACKS.

THE GROUND OR IN THE EXTEND POSITION. THIS

THE LEVELING JACKS ARE STILL IN CONTACT WITH

DO NOT MOVE THE VEHICLE WHILECAUTION:

Maintain adequate clearance in all directions for vehicle, room

extensions, awnings, doors, steps, etc. Vehicle may move in

any direction due to jacks extending or retracting, settling of

the jacks or the vehicle, equipment malfunction, etc..

Any room extension, jacks, joey beds or generator slides

DO NOT MOVE THE VEHICLE IF ONE

OR MORE JACKS ARE EXTENDED TO THE GROUND.

CAUTION:

should be fully retracted before traveling.

JACKS AND OR THE VEHICLE AND CREATE A DRIVING

HAZARD. DO NOT RELY SOLELY UPON WARNING

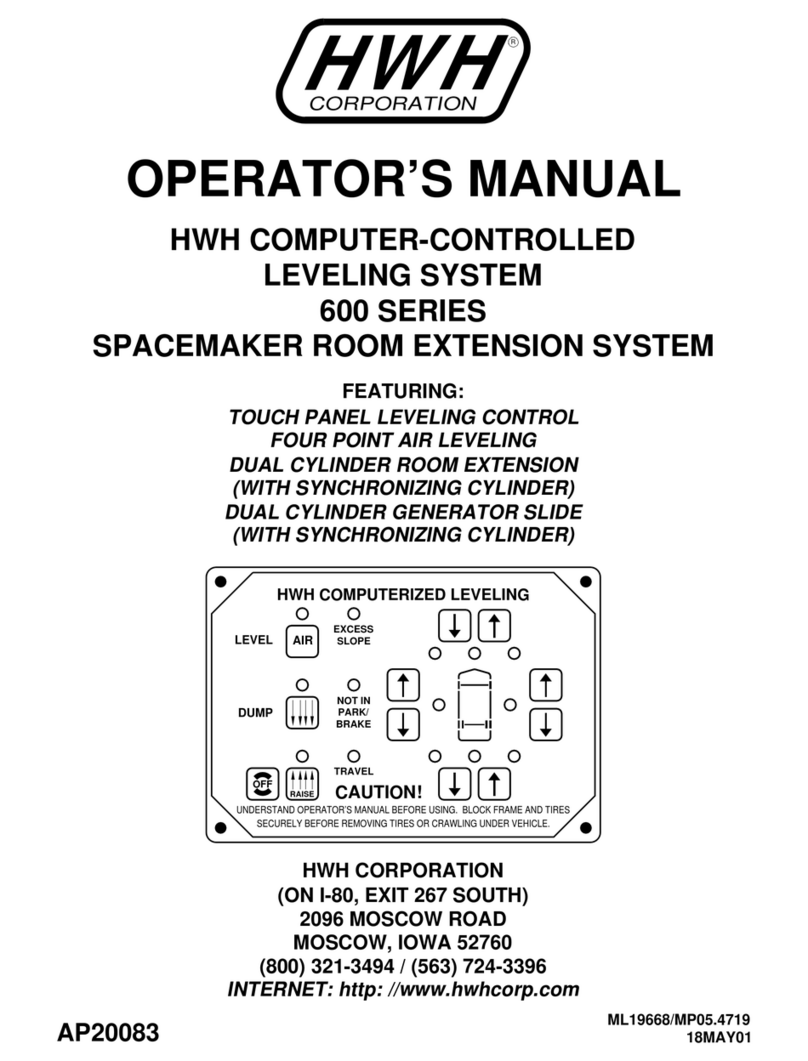

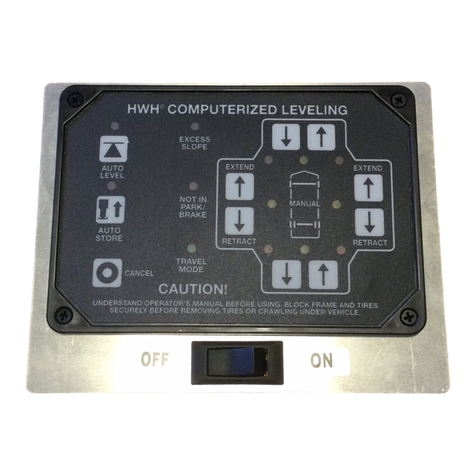

The main controls for the leveling system and room extensions

are supplied by the vehicle manufacturer. Refer to the vehicle

fail to retract completely, extend the jacks back down

to the ground then retract the jacks again.

NOTE: If the vehicle is parked or stored with the jacks

extended for an extended period of time and the jacks

INDICATORS. IT IS THE OPERATOR’S RESPONSIBILITY

TO CHECK THAT ALL JACKS ARE FULLY RETRACTED

INTO THE STORE/TRAVEL POSITION.

MASTER JACKS DOWN WARNING LIGHT:

manufacturer for leveling system and room extension control

instructions.

The park brake must be set to use the leveling system,

room extensions and joey beds.

The Master

Jacks Down Warning light is on the auxiliary switch panel

below the HWH Reset Switch.

HWH LIGHTED RESET SWITCH

continuing hydraulic operations.

operation can continue. Allow the pump to cool before

ignition is on. The reset button must be pushed before any

CAN network down. The lighted reset switch will be on if the

Excessive operation of the hydraulic pump can shut the HWH

before any room or the leveling system can be operated.

If the lighted reset switch is on, the switch must be pushed

THE VEHICLE CAN RETURN TO RIDE HEIGHT WITHOUT

POSITION AND THE LIGHTED RESET SWITCH IS ON,

IF THE IGNITION IS IN THE "ON"

The vehicle suspension will return to the travel mode if the

system. No rooms or the Leveling System will operate.

is a problem with the central control module of the network

If the lighted reset switch will not go out when pushed, there

the other rooms or leveling system after the reset switch is

the use of the room extensions after the reset switch is

A network problem with the leveling system will not inhibit

A network problem with one room will not inhibit the use of

ignition key is in the "ON" position.

RELEASING THE PARK BRAKE.

CAUTION:

pushed.

pushed.

The HWH lighted reset switch is located on the auxiliary

switch panel in the hydraulic pump compartment. If there is a

failure at any time in the HWH CAN network, the network will

shut down. The leveling system and all room extensions will

not operate. If the ignition is off, no indicator lights will come

on. If the ignition is in the "ON" position, the lighted reset

switch and the MASTER WARNING Light will come on.

OPERATING PROCEDURES

APEX SYSTEM