MP34.2751B

20JUN1

OPERATING PROCEDURES

725 SERIES LEVELING SYSTEM

or level the vehicle as close as possible according to the

to retract the jacks. Move the vehicle to a more level position

turning the red warning lights out. Push the "STORE" button

SLOPE" light will remain on if the ignition is in the "ON" or

One or more jacks may not be extended. The system will sh

stabilize the vehicle if the "EXCESS SLOPE" light comes on

without turning the yellow level light out. The system will no

come on. Excess slope is one or two jacks fully extending

unable to level the coach, the "EXCESS SLOPE" light will

EXCESS SLOPE SITUATION: In the event the jacks are

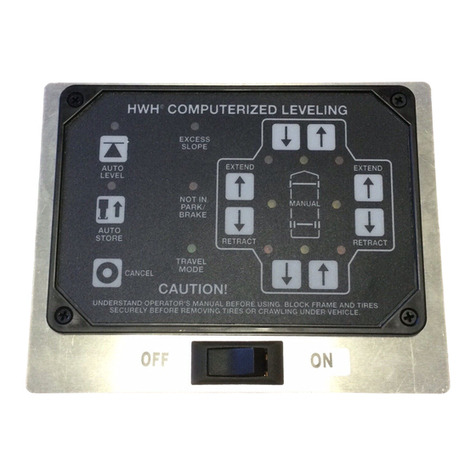

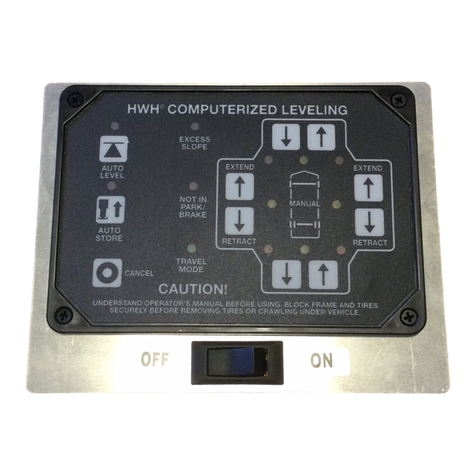

AUTOMATIC HYDRAULIC LEVELING (HWH TOUCH PANEL CONTROLS)

the vehicle ignition is in the ON or ACC. position

the leveling system touch panel can be on anytime

NOTE: One or two yellow level indicator lights on

the automatic leveling function.

"CANCEL" button on the HWH touch panel will stop

pushing the "AUTO LEVEL", "AUTO STORE" or the

IMPORTANT: During the Automatic Leveling procedures,

and place a pad under each jack if the ground will not

2. At this time, the operator may want to check the jacks

engine off. Turn the ignition to the "ACCESSORY" position.

parking the vehicle and set parking brake. Turn the coach

1. Place transmission in the recommended position for

and the park brake is set.

support the vehicle.

MANUAL HYDRAULIC OPERATION section.

"ACC" position, until the jacks have been fully retracted

off leaving the "EXCESS SLOPE" light on. The "EXCESS

5. Turn the ignition switch to the "OFF" position.

The slight lift experienced during the stabilizing procedure

normally is not sufficient to cause a level issue for the motor

home. However, a feature of the single step leveling system

is the manual leveling buttons will function anytime the

ignition is in the ON or ACC. position and the park brake is

set. If desired, the operator can use the UP ARROWS

(extend jacks) that correspond to any lit yellow level indicato

light to "bump" the vehicle up slightly to turn that yellow

indicator light off.

During the automatic

leveling sequence, after the system has extended the

appropriate jacks to level the vehicle and has turned

the yellow level indicator lights off, the system will

then stabilize the vehicle.

The switch will turn on when the jack extends to the ground

and lifts the vehicle slightly. Jacks that have lifted the vehicle

for leveling should have pressure switches that are on.

The stabilize procedure is a specific sequence where the

computer checks the jack pressure switches. If the switch

is on, the jack is already stabilizing the vehicle. If the switch

is not on, the computer turns the pump and valve on for that

jack until the pressure switch turns on.

The sequence starts with the right rear jack. If the pressure

switch is not on, the system will extend the jack as necessary

If the switch is on (or when it comes on) the system will check

the left rear jack pressure switch, extending the jack if necessary

If the left rear switch is on (or when it comes on), the system

will recheck the right rear (extending if necessary) then recheck

the left rear (extending if necessary). After checking and

rechecking both rear jacks, the system then checks the fron

jacks. The system checks both front jacks at the same time

If either pressure switch is not on, the system will turn the

pump on and open the valves for both front jacks. When

If at this time a yellow level light is on, the system will

automatically repeat the leveling sequence. The repeat

sequence will only happen if a yellow level light is on at

the end of the initial leveling and stabilizing sequence.

If a yellow level light is still on after the repeat sequence,

the system will turn off, leaving the level light on.

both front pressure switches are on, the system turns the

pump and front valves off.

THE "AUTO LEVEL" BUTTON IS PUSHED.

AIR WILL BE EXHAUSTED FROM THE VEHICLE SUSPENSION

AND THE VEHICLE WILL LOWER IMMEDIATELY AFTER

BUTTON THE OPERATOR MUST BE SURE THAT ALL

PERSONS AND OBJECTS ARE CLEAR OF THE VEHICLE.

will begin to dump air from the vehicle suspension. After

approximately 25 seconds, the leveling process will begin.

The AUTO LEVEL light will start to flash. The system

3. Press the "AUTO LEVEL" button one time.

WARNING:

PRIOR TO PUSHING THE "AUTO LEVEL"

When a jack extends approximately 1 inch, it’s individual

red warning light on the touch panel will come on. The

touch panel "TRAVEL MODE" light will go out. If the

ignition is in the ON position, the warning buzzer will

sound.

AUTO LEVEL SEQUENCE:

STABILIZE SEQUENCE: The stabilize sequence is part of

the Auto Level sequence. Each jack has a pressure switch.

NOTE: If a room control switch is used while the leveling

system is in the AUTO LEVEL mode, the leveling sequence

will be interrupted. When the room control switch is

released, the leveling sequence will resume.