TABLE OF CONTENTS

NOTES.......................................................................................................................................................................................... 2

FOREWORD ................................................................................................................................................................................ 3

TABLE OF CONTENTS............................................................................................................................................................... 4

INDEX OF FIGURES.................................................................................................................................................................... 5

SECTION 1 | SAFETY.................................................................................................................................................................. 6

1.1 | SAFETY SYMBOLS.......................................................................................................................................................................... 6

1.2 | GENERAL RULES AND PRECAUTIONS ................................................................................................................................... 6

1.3 | SAFETY GUIDELINES.................................................................................................................................................................... 7

SECTION 2 | MAINTENANCE ................................................................................................................................................... 8

2.1 | BATTERY MAINTENANCE........................................................................................................................................................... 8

2.2 | CHARGING THE BATTERY.........................................................................................................................................................8

2.3 | LUBRICATION.............................................................................................................................................................................. 10

2.4 | COMPONENTS REQUIRING ADJUSTMENT....................................................................................................................... 10

2.5 | EXAMINATION, REPAIR, REPLACEMENT OF LIMITED LIFE COMPONENTS..............................................................10

2.6 | SAFETY DEVICES AND SYSTEMS REQUIRING CHECKS ............................................................................................... 10

2.7 | STORAGE......................................................................................................................................................................................10

2.8 | MAJOR ALTERATIONS OR REPAIRS...................................................................................................................................... 10

2.9 | OTHER PROCEDURES.............................................................................................................................................................. 10

SECTION 3 | MAINTENANCE CHECKLISTS ..........................................................................................................................11

3.1 | PRESTART INSPECTION CHECKLIST................................................................................................................................... 12

3.2 | MONTHLY INSPECTION CHECKLIST ................................................................................................................................... 13

3.1 | PREDELIVERY/ANNUAL/FREQUENT INSPECTION CHECKLIST................................................................................... 14

SECTION 4 | TECHNICAL REFERENCES .............................................................................................................................. 16

4.1 | HYDRAULIC SCHEMATIC ......................................................................................................................................................... 16

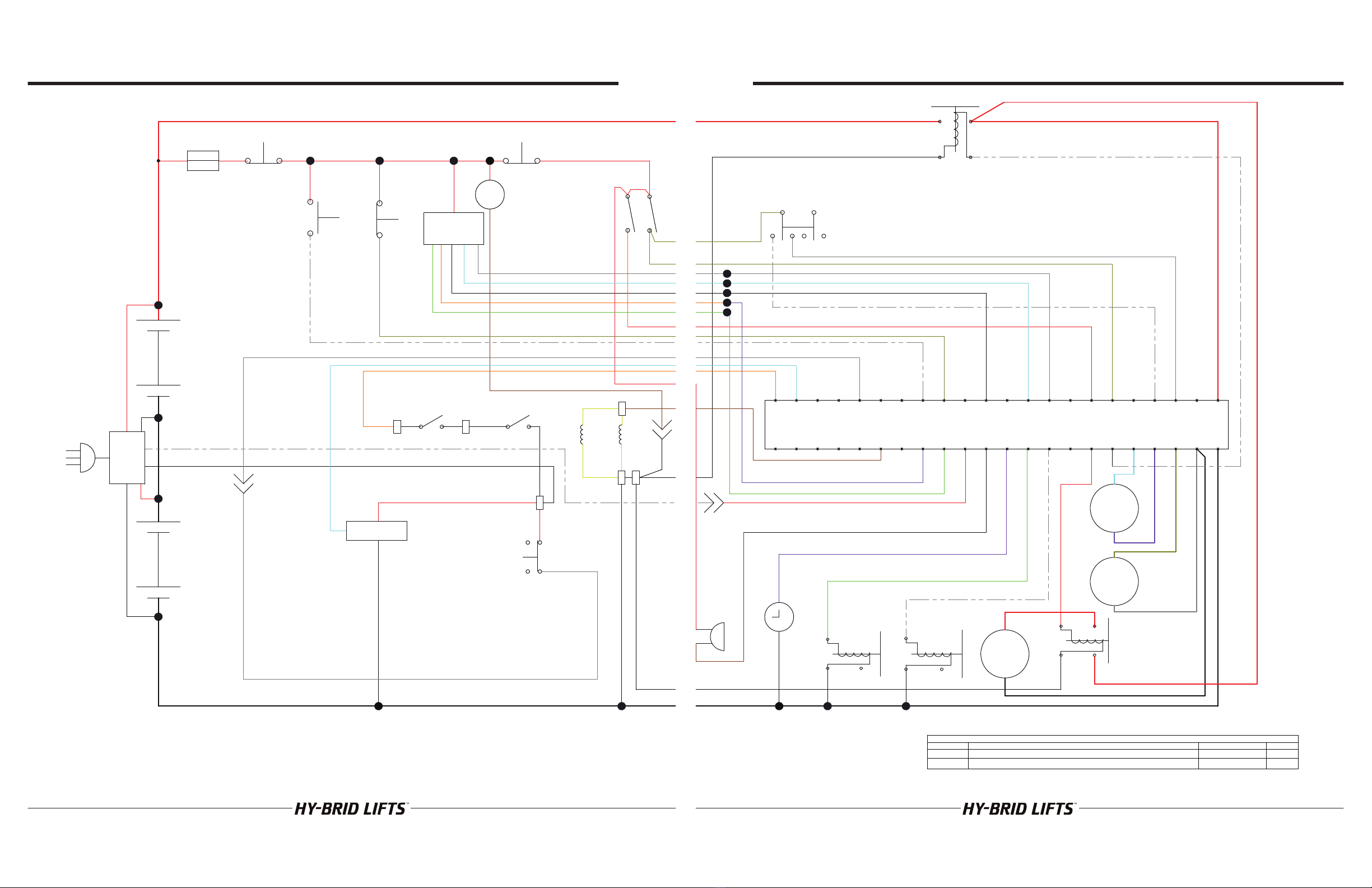

4.2 | ELECTRICAL SCHEMATIC........................................................................................................................................................ 18

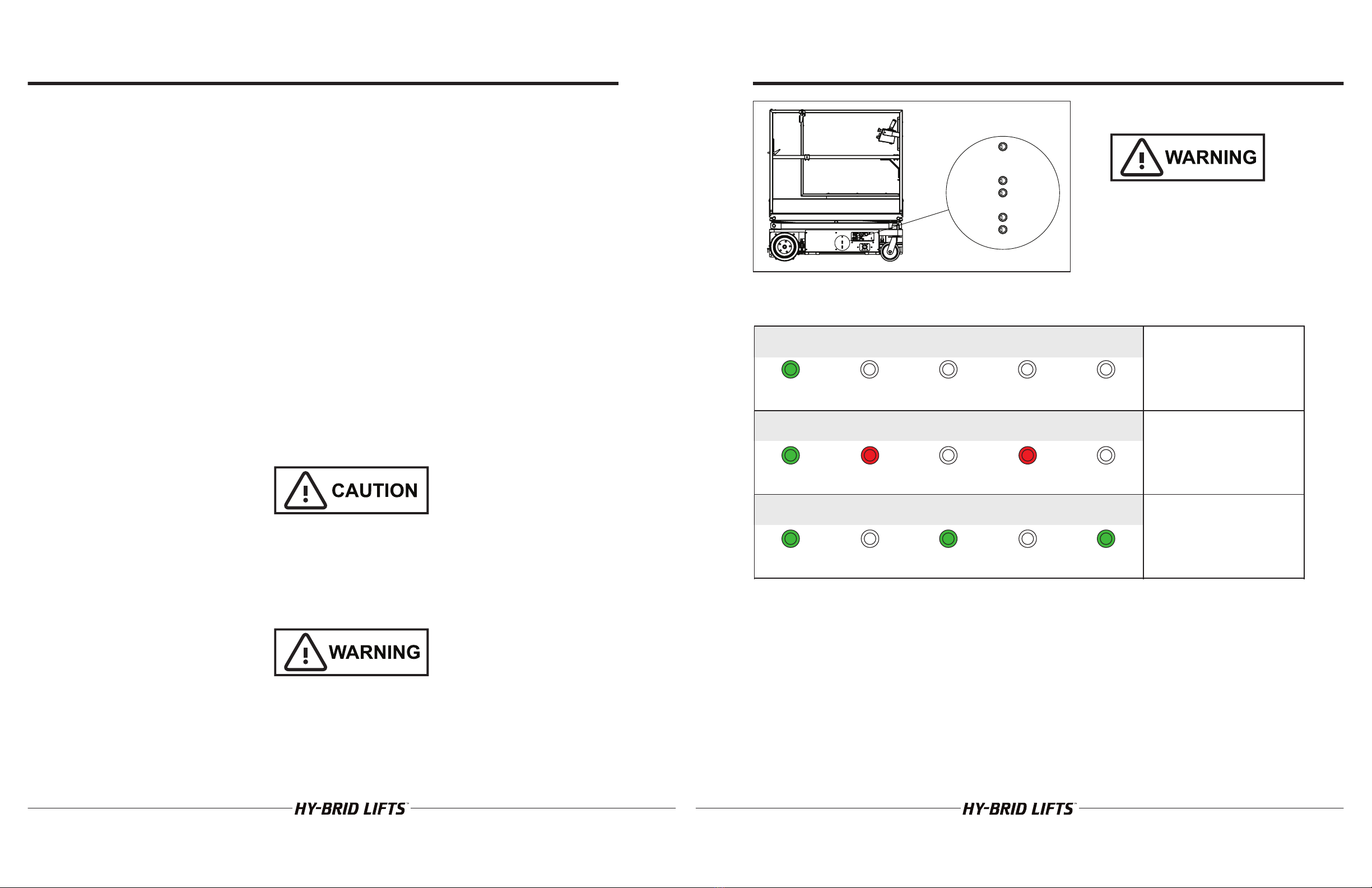

4.3 | CONTROL BOARD DIAGNOSTICS........................................................................................................................................20

SECTION 5 | WIRING DIAGRAMS.......................................................................................................................................... 22

5.1 | WIRING DIAGRAM .....................................................................................................................................................................23

5.2 | LOWER CONTROLS WIRING DIAGRAM ..............................................................................................................................24

5.3 | UPPER CONTROLS WIRING DIAGRAM................................................................................................................................26

5.4 | MAIN POWER/SAFETY CIRCUIT.............................................................................................................................................28

5.5 | DRIVE CIRCUIT ...........................................................................................................................................................................30

5.6 | ELEVATE/LOWER CIRCUIT ......................................................................................................................................................32

SECTION 6 | TROUBLESHOOTING FLOWCHARTS ...........................................................................................................34

6.1 | MAIN POWER/SAFETY CIRCUIT.............................................................................................................................................34

6.2 | DRIVE CIRCUIT...........................................................................................................................................................................36

6.3 | ELEVATE CIRCUIT ......................................................................................................................................................................38

6.4 | LOWER CIRCUIT........................................................................................................................................................................ 40

SECTION 7 | PARTS DIAGRAMS.............................................................................................................................................42

7.1 | SAFETY AND CONTROL DECALS...........................................................................................................................................42

7.2 | MAIN POWER/SAFETY CIRCUIT .............................................................................................................................................43

7.3 | DRIVE CIRCUIT............................................................................................................................................................................44

7.4 | ELEVATE / LOWER CIRCUIT ....................................................................................................................................................46

7.5 | COVERS.........................................................................................................................................................................................48

7.6 | RAILINGS.......................................................................................................................................................................................49

SECTION 8 | WARRANTY........................................................................................................................................................50

SECTION 9 | ADDITIONAL RESOURCES .............................................................................................................................. 52

NOTES........................................................................................................................................................................................54

MAINTENANCE & TROUBLESHOOTING

HB1230

SUPO646

REV A

4

Revision Log

Revision A..........................................................................................................................................................................December 2013

INDEX OF FIGURES

FIGURE 1: Battery Charger LED Display .............................................................................................................................................. 9

MAINTENANCE & TROUBLESHOOTING

HB1230

SUPO646

REV A

5