2

Safety Precautions

1. Always use protective earplugs even though the powerpack has a low noise

level.

2. Always connect hoses efore starting.

3. Always keep electric ox, ca les and sockets clean.

4. In case of non-operation or performance of service, always turn off the motor.

5. Never start the motor without side covers.

6. Operation of the powerpack without tool connected and with lever at “ON” may

cause overheating of the system and damage to the powerpack.

7. When lifting the powerpack from a vehicle, we recommend the use of a crane.

8. The pressure relief valve is set at 160 ar from our plant. Never set it higher.

9. Always use filters with y-pass. The use of filters without y-pass may low the

hydraulic hoses and the filter cover.

10. Never perform service on the powerpack without disconnecting the power

supply.

Filling p Hydraulic Oil

•For påfyldning af hydraulikolie løsnes

filterlåget øverst på drivstationen

•Herefter tages filterindsatsen ud (se

foto) og der kan nu fyldes olie på.

Når der kan ses olie i unden af filter-

enheden, er der olie nok på.

•Filterindsatsen sættes i igen, låget

monteres, og drivstationen er nu klar

til rug.

Vær opmærksom på, at ved tilko ling af nye

forlængerslanger, vil der skulle påfyldes 2

liter olie mere. Derfor skal drivstationen

efterfyldes, hvis der tilko les nye slanger.

•To fill up with hydraulic oil, loosen the

filter cover on top of the powerpack.

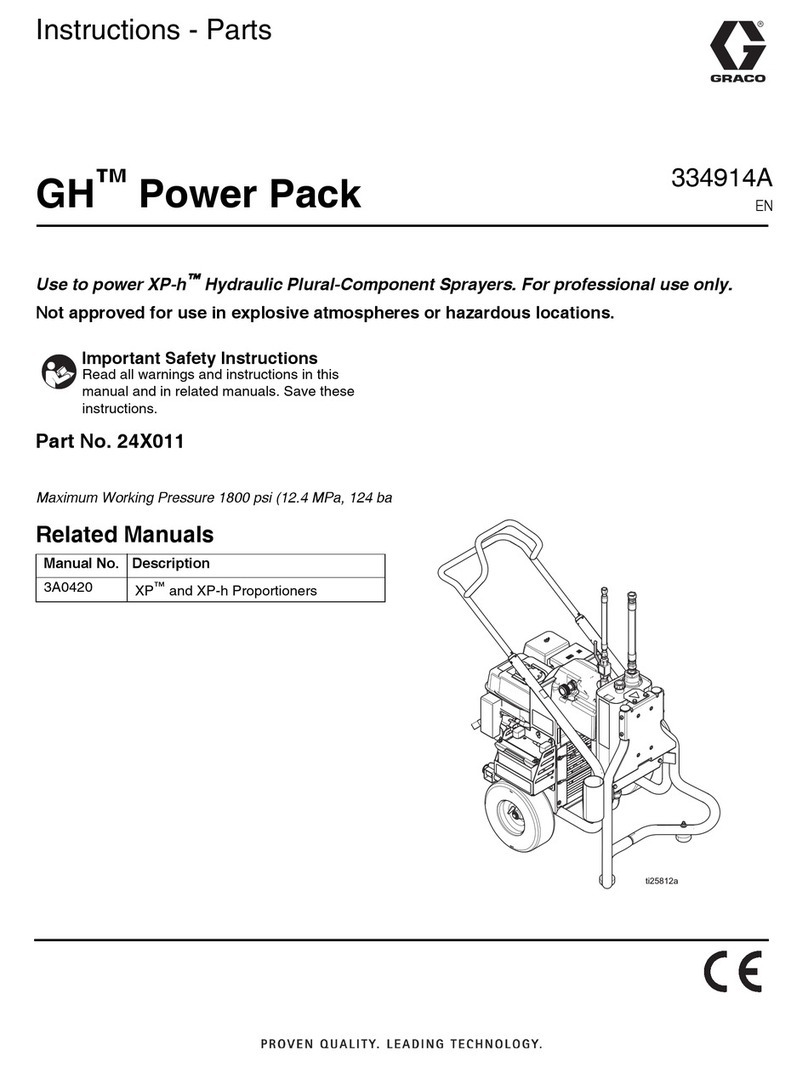

•Remove the filter element (see photo),

and fill up with oil. When oil is showing

at the ottom of the filter unit, there is

enough oil on the powerpack.

•Insert the filter element again, mount

the cover and the powerpack is ready

for use.

Please note: When connecting new extension

hoses, it is necessary to fill up with extra 2 litres of

oil. Therefore always top up the powerpack when

connecting new extension hoses.