Hycontrol Ltd V1.5

Page 8

5) COMMISSIONING

5.1) Setting-Up

There is very little to set u as in most cases the sensor can be fitted without any

adjustment. However there are adjustments for sensitivity and res onse time, should they be

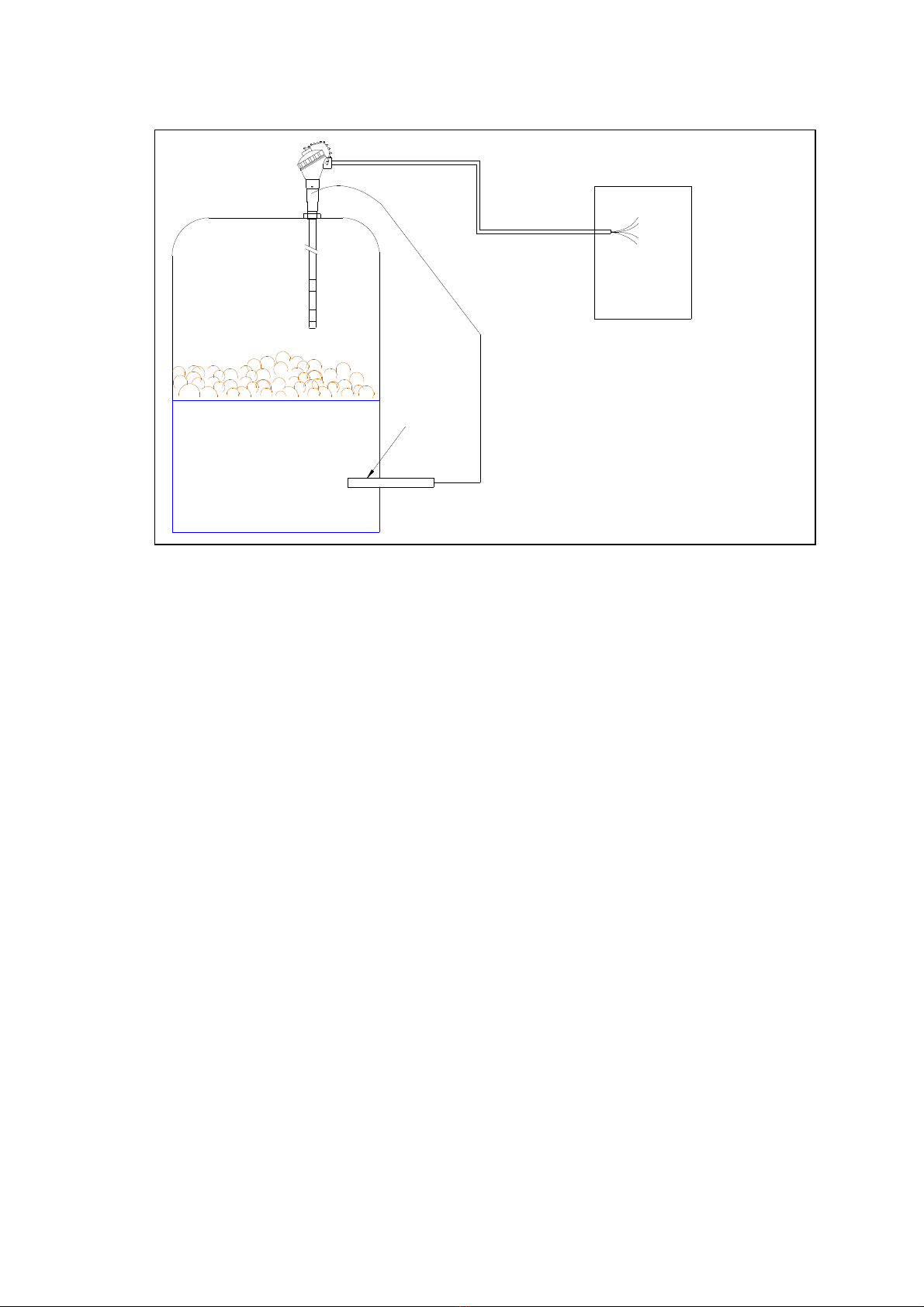

needed. To test the sensitivity arrange for the foam to increase to reach the sensor. The

sense electrode at the send of the sensor is the sensitive art. Once the foam makes a good

contact with the sense electrode the robe should be able to detect the foam. If it’s

im ractical to make foam for a test then a sim le test is to touch the end of the sensor

against the wall of the tank. This is a very coarse test and does not show that it will measure

the foam, however it will trigger the sensor to allow the connections to be tested.

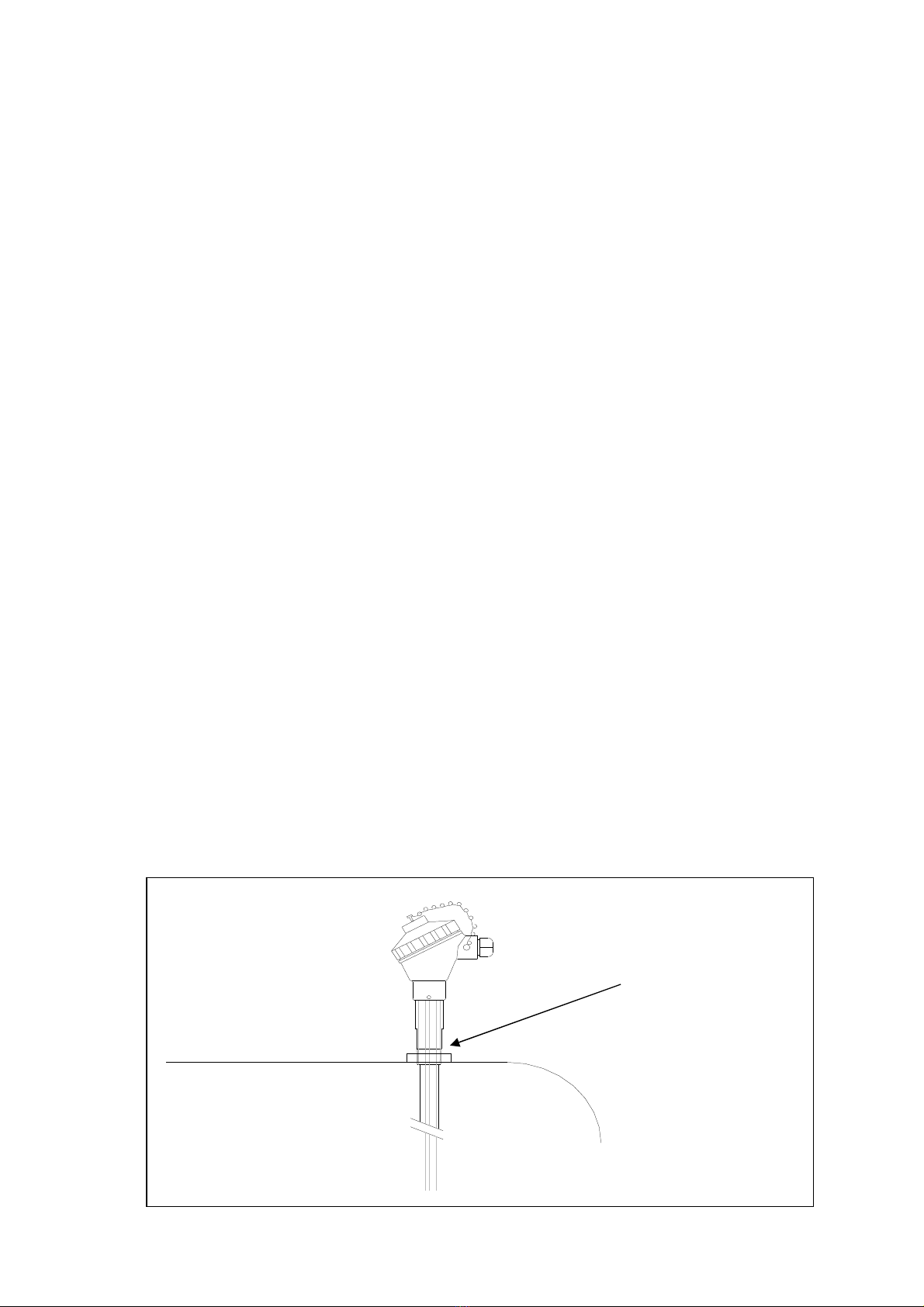

If the test above does not trigger the sensor then there is almost certainly an earth return

roblem.

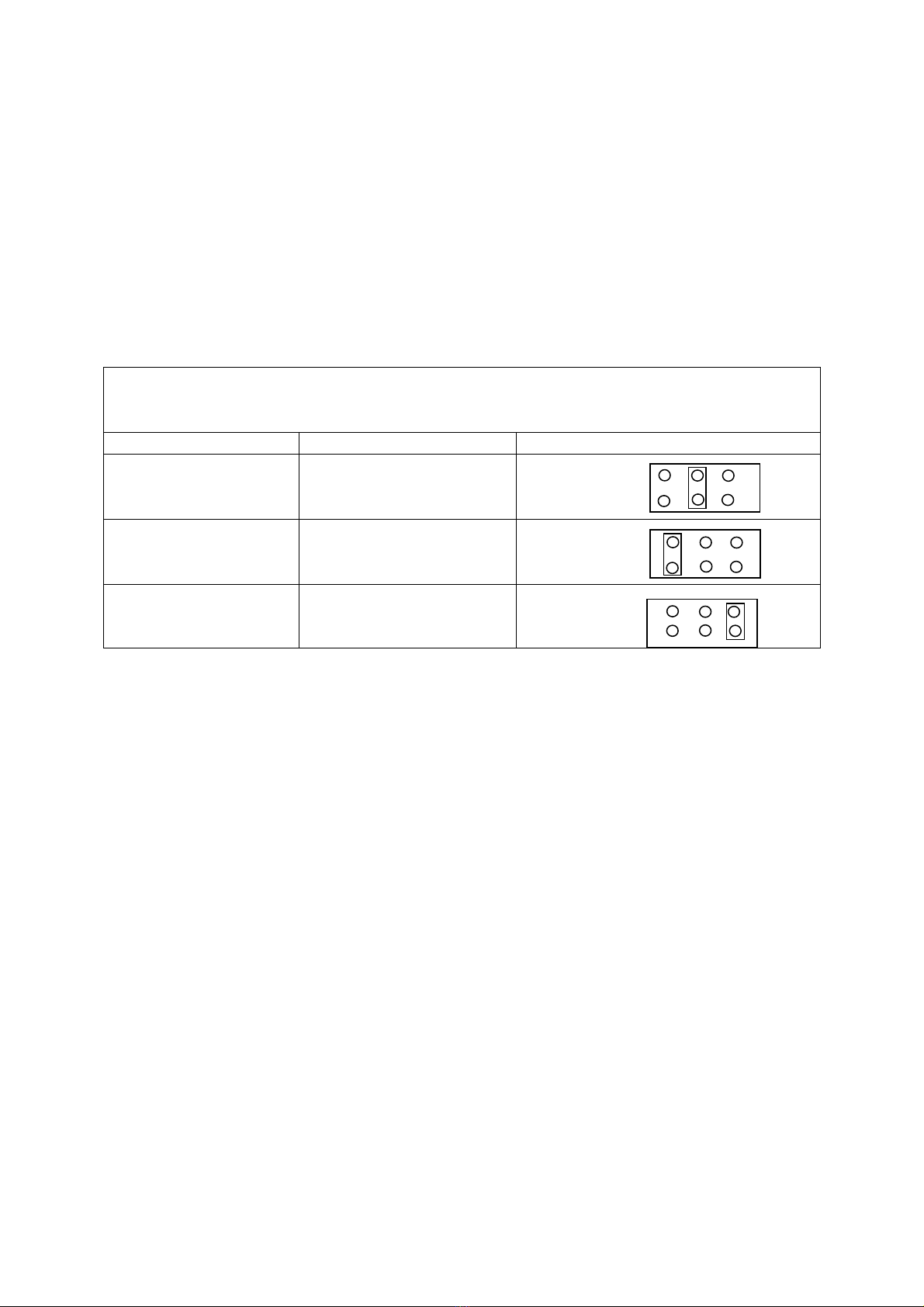

5.2) Sensitivity Setting

The sensitivity can be set by the small adjuster in the head. The adjustment is from 0 –9

where 0 is the lowest sensitivity. The factory setting of 5 is suitable for most a lications.

However if the foam is very light the sensitivity may need to be increased. Alternatively with

very dense sticky foam it is advisable to reduce the sensitivity. See Table 1 below for more

details of the sensitivity settings. .

If the sensor is in contact with foam but does not trigger then increase the sensitivity

setting to a higher figure.

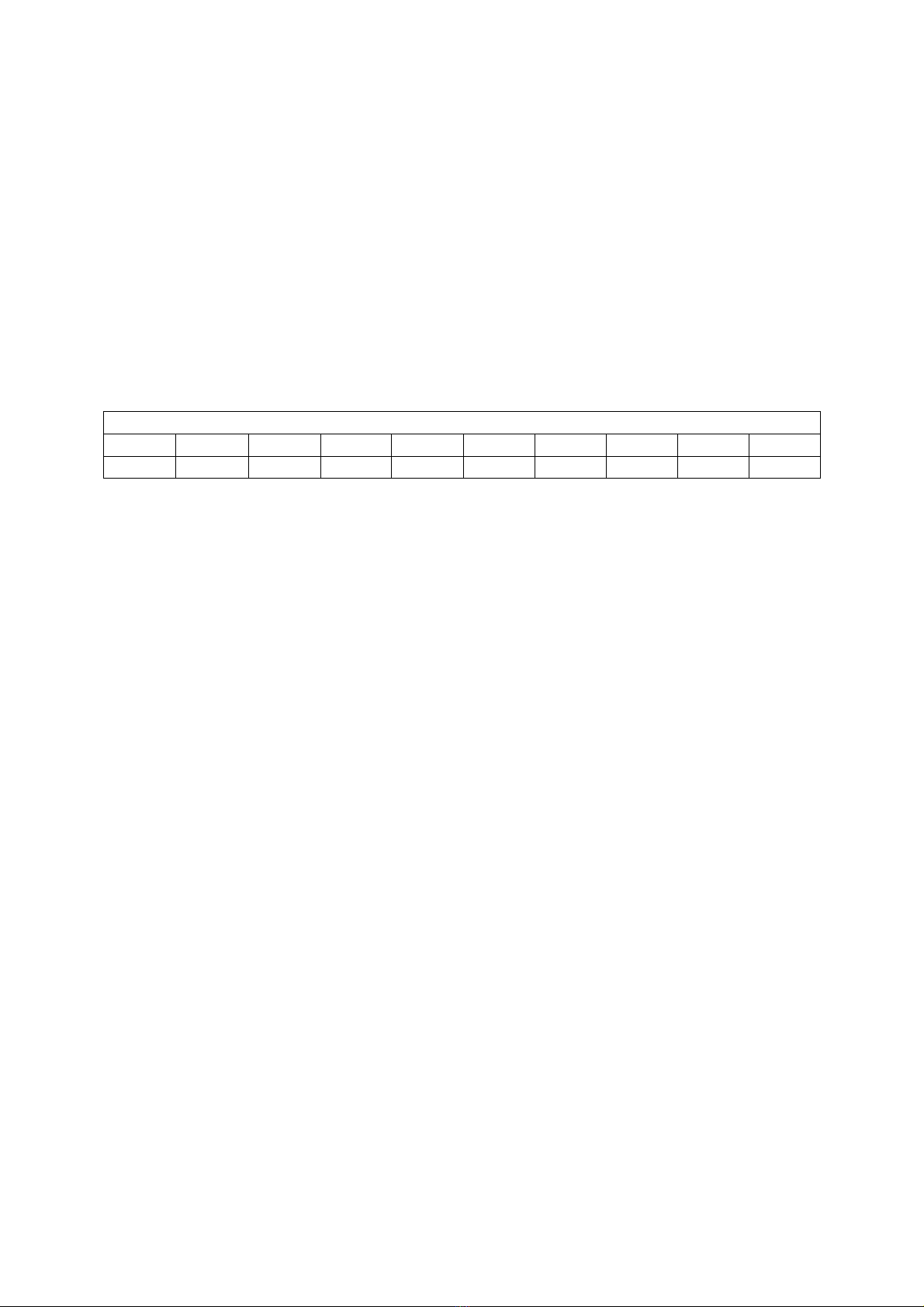

Table 1 Sensitivity Adjustment – SW2

Sensitivity Setting Application

0 Liquid Lowest Sensitivity

1 Very dense heavy foam

2 Processed food with high salt level

3 Waste water with high solids

4 Waste water

5 Most applications Default Setting

6

7 Light foam from detergent

8

Very light foam Highest Sensitivity