INSTALLATION INSTRUCTIONS

12881 Bradley Ave

Sylmar,CA91342

Phone: 818-362-9465

Fax:818-362-6548

www.hydrel.com

©2007 Acuity Brands Lighting, Inc.

Rev. 11/28/07

INS-PDX7_REV0

NOTE: HYDREL RESERVES THE RIGHT TO MODIFY SPECIFICATION WITHOUT

NOTICE. Any dimension on this sheet is to be assumed as a reference

dimension: "Used for information purposes only. It does not govern

manufacturing or inspection requirements." (ANSI Y14.5-1973)

PARADOXSERIES

PDX7

Installation should be performed by a qualified

electrician in accordance with the National Electrical Code

and relevant local codes.

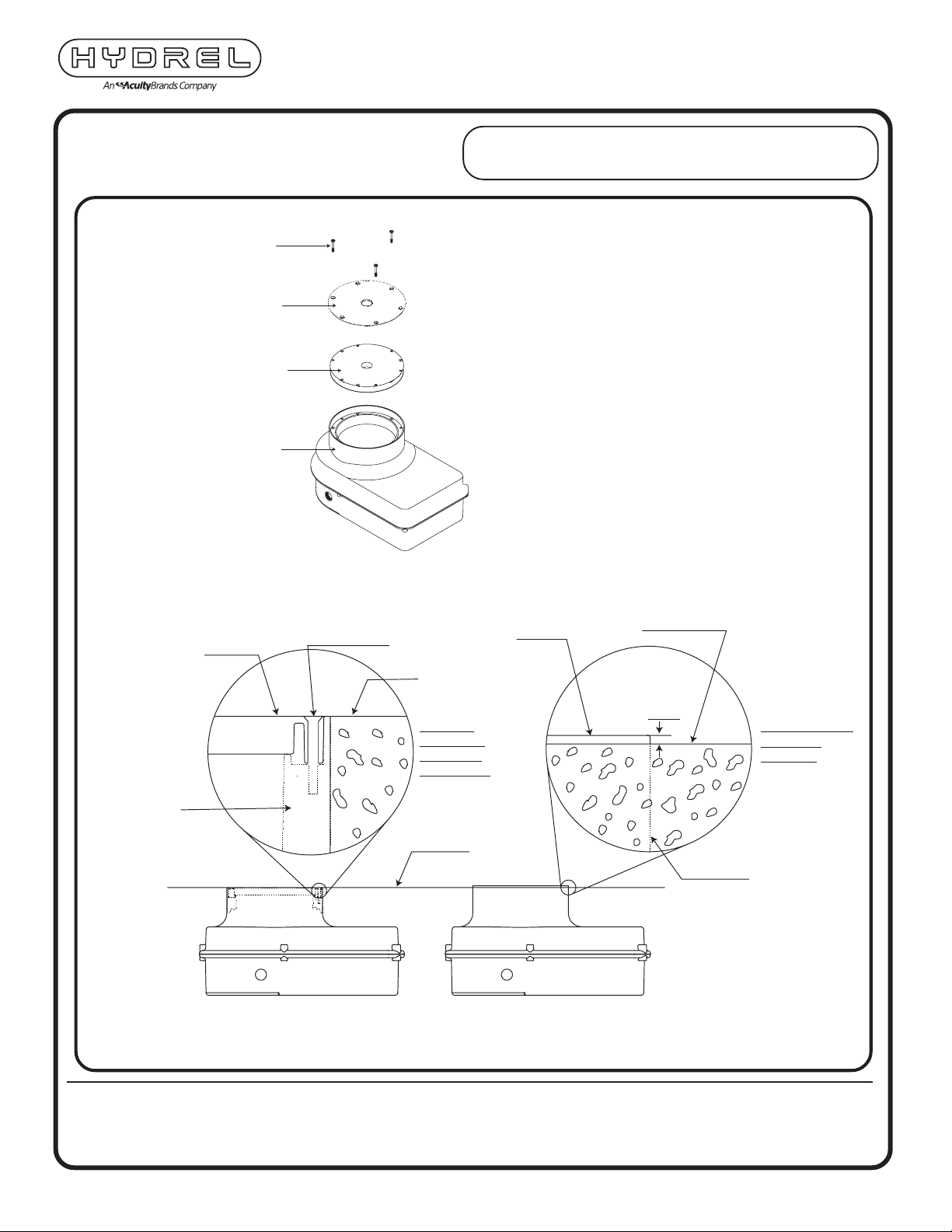

5. Remove temporary cover or tempo-

rary cover and flush pour shield.

6. Loosen junction box screw and re-

move lid.

IMPORTANT NOTE:

Do

NOT lose screw. Screw contains an

O-ring seal. It MUST be used to rein-

stall junction box lid in Step 9.

7. Connect 3/4” NPT conduit to junction box

(side or bottom entry). Seal conduit entry

using suitable thread sealing compound

to ensure conduit is watertight and to

prevent moisture penetration from con-

duit system.

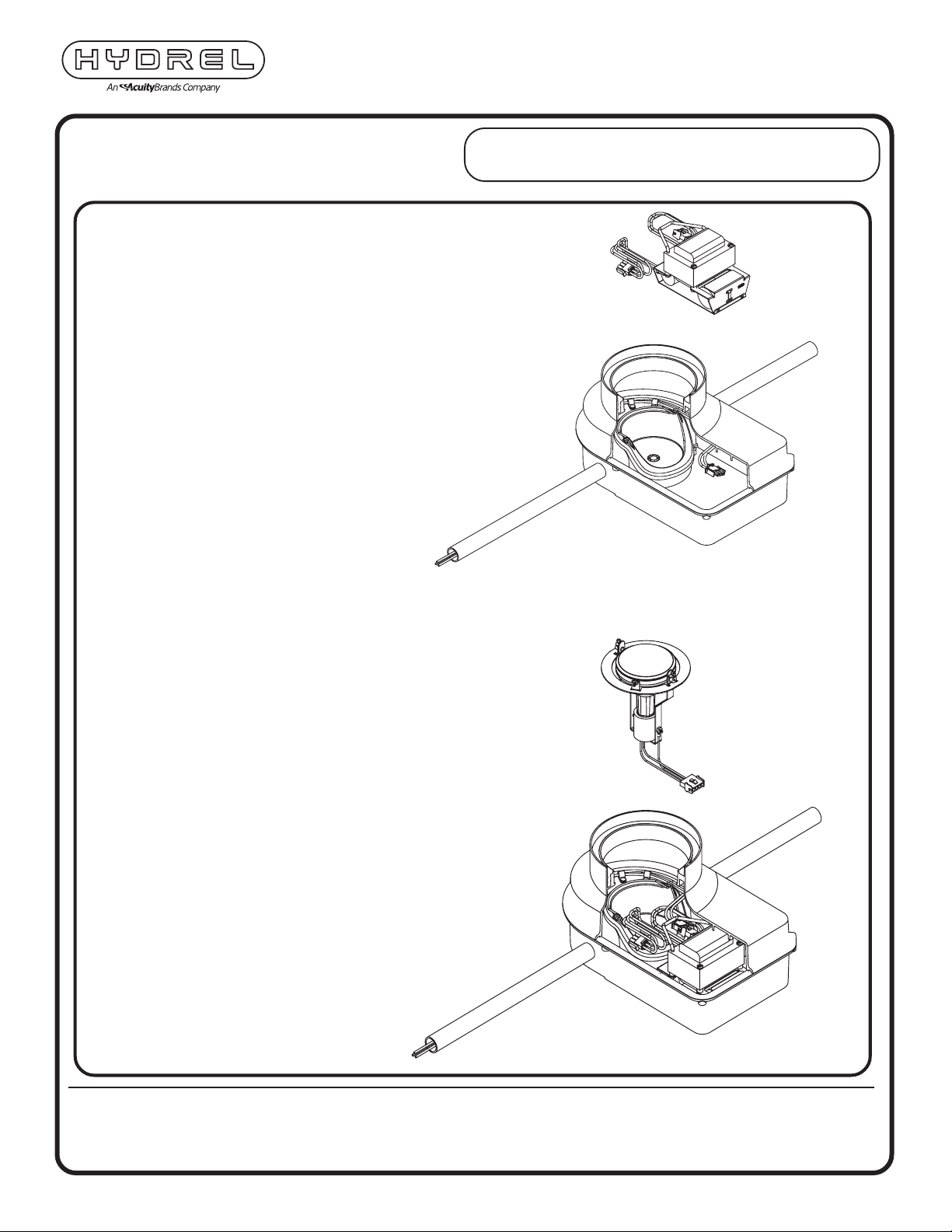

8. Pull electrical supply conductors and

make wire splice in accordance with

NEC.

9. Reinstall junction box lid with

O-ring screw provided.

CAUTION: DO NOT OVER

TIGHTEN (20 IN-LBS OR 2 n-M).

▲