Downstream Defender®Operation and Maintenance ManualDownstream Defender®Operation and Maintenance Manual

Hydro International (Stormwater), 94 Hutchins Drive, Portland ME 04102

Tel: (207) 756-6200 Fax: (207) 756-6212 Web: www.hydro-int.com

Operation

Introduction

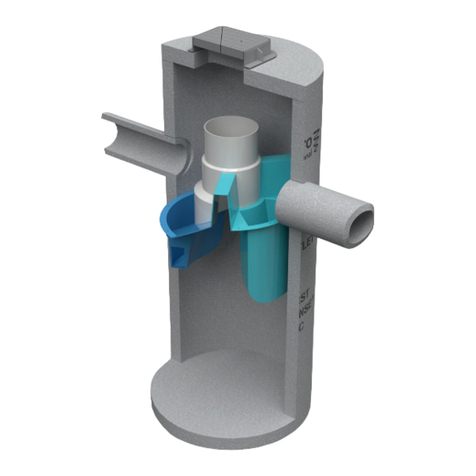

The Downstream Defender®

components. No manual procedures are required to operate

the unit and maintenance is limited to monitoring accumulations

Defender®

the unit or removal of the internal components is not necessary

entry are avoided.

Pollutant Capture and Retention

The internal components of the Downstream Defender®have

volumes so that separator performance is not reduced as pollutants

Defender®is designed and installed into the storm drain system

separate from the sediment storage volume in the sump of the

unit providing the option for separate oil disposal, and accessories

storage volumes are isolated from the active separation region,

Wet Sump

The sump of the Downstream Defender®retains a standing water

Maintenance

Overview

The Downstream Defender®

Periodic removal of these captured pollutants is essential to the

®.

The Downstream Defender®will capture and retain sediment and

oil until the sediment and oil storage volumes are full to capacity.

When sediment and oil storage capacities are reached, the

Downstream Defender®

sediment and oil. Maximum pollutant storage capacities are

The Downstream Defender®allows for easy and safe inspection,

plate. The sediment removal access ports for all Downstream

Defender®

Removal, and Sediment Removal. Maintenance events do not

require entry into the Downstream Defender®, nor do they require

the internal components of the Downstream Defender®

vactor truck is not required. However, a vactor truck is required if

the maintenance event is to include oil removal and/or sediment

removal.

Determining Your Maintenance Schedule

inspected every six months to determine the rate of sediment and

®

®typically takes less than

Inspection Procedures

Inspection is a simple process that does not involve entry into the

Downstream Defender®

with the Downstream Defender®and its components prior to

inspection.

Scheduling

• It is important to inspect your Downstream Defender®every

•

of the year

• Sediment removal is not required unless sediment depths

Recommended Equipment

•Safety Equipment and Personal Protective Equipment

•

•Pole with skimmer or net

• ®)

•

NOTES

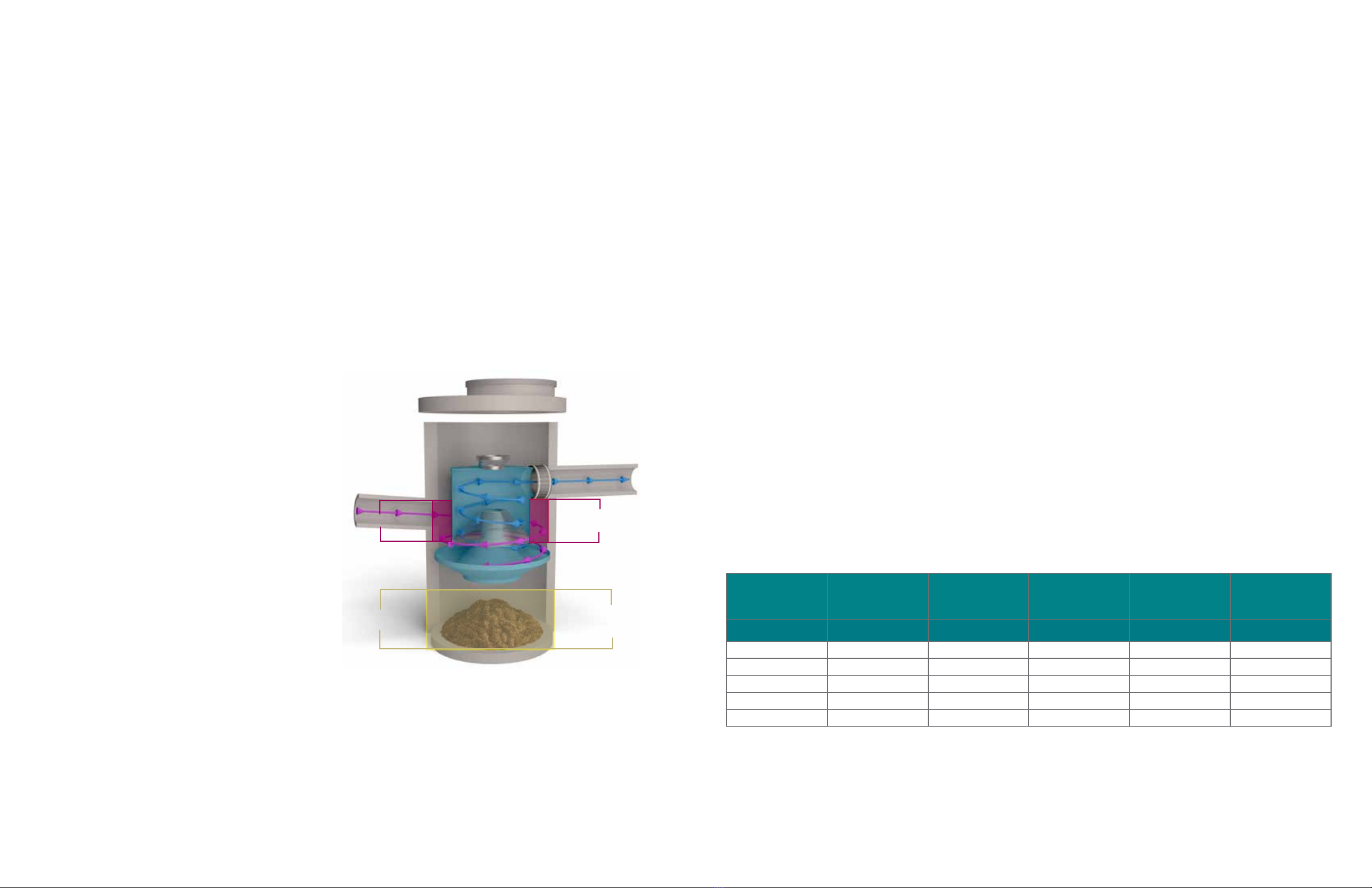

1. Refer to Dowmstream Defender®

2. Oil accumulation is typically less than sediment, however, removal of oil and sediment during the same service is recommended.

3.

4.

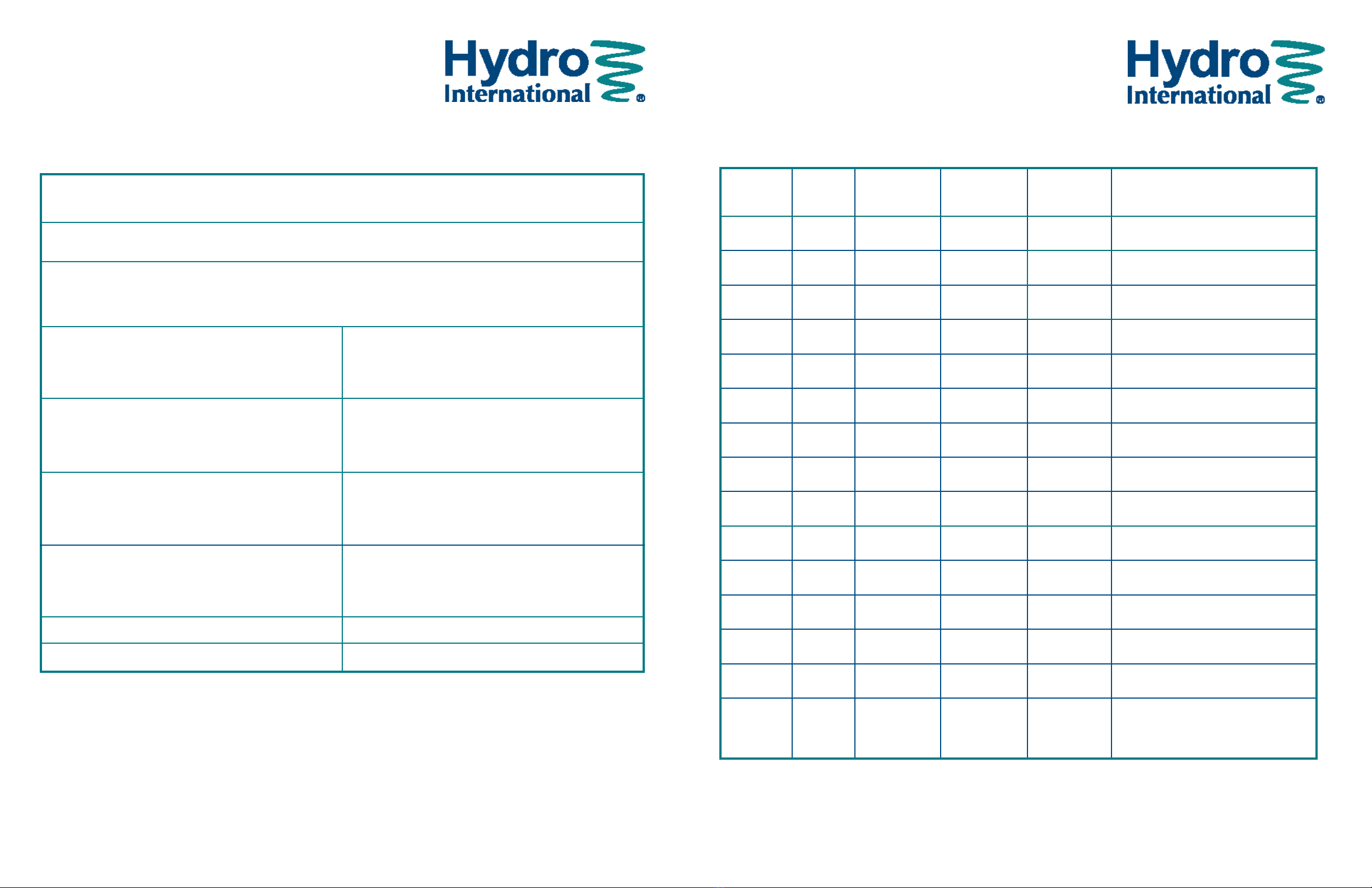

Downstream Defender®Pollutant Storage Capacities and Max. Cleanout Depths.

Fig.1 Pollutant storage volumes of the Downswtream Defender®.

Oil Max Oil

Storage Depth

Isolated Sediment

Storage

Sediment

Unit Diameter Total Oil Storage Total Sediment

Storage

Sediment

Max. Liquid Volume

Removed

(feet) (gallons) (inches) (gallons) (inches) (gallons)

4 <16 141

6 216 <23 424 <24 1,239

<33 939

<42 1,757 <36 5,546

12 <49 <42

Page | 4 Page | 5