Up-Flo®Filter Operation and Maintenance Manual

Hydro International (Stormwater), 94 Hutchins Drive, Portland ME 04102

Tel: (207) 756-6200 Fax: (207) 756-6212 Web: www.hydro-int.com

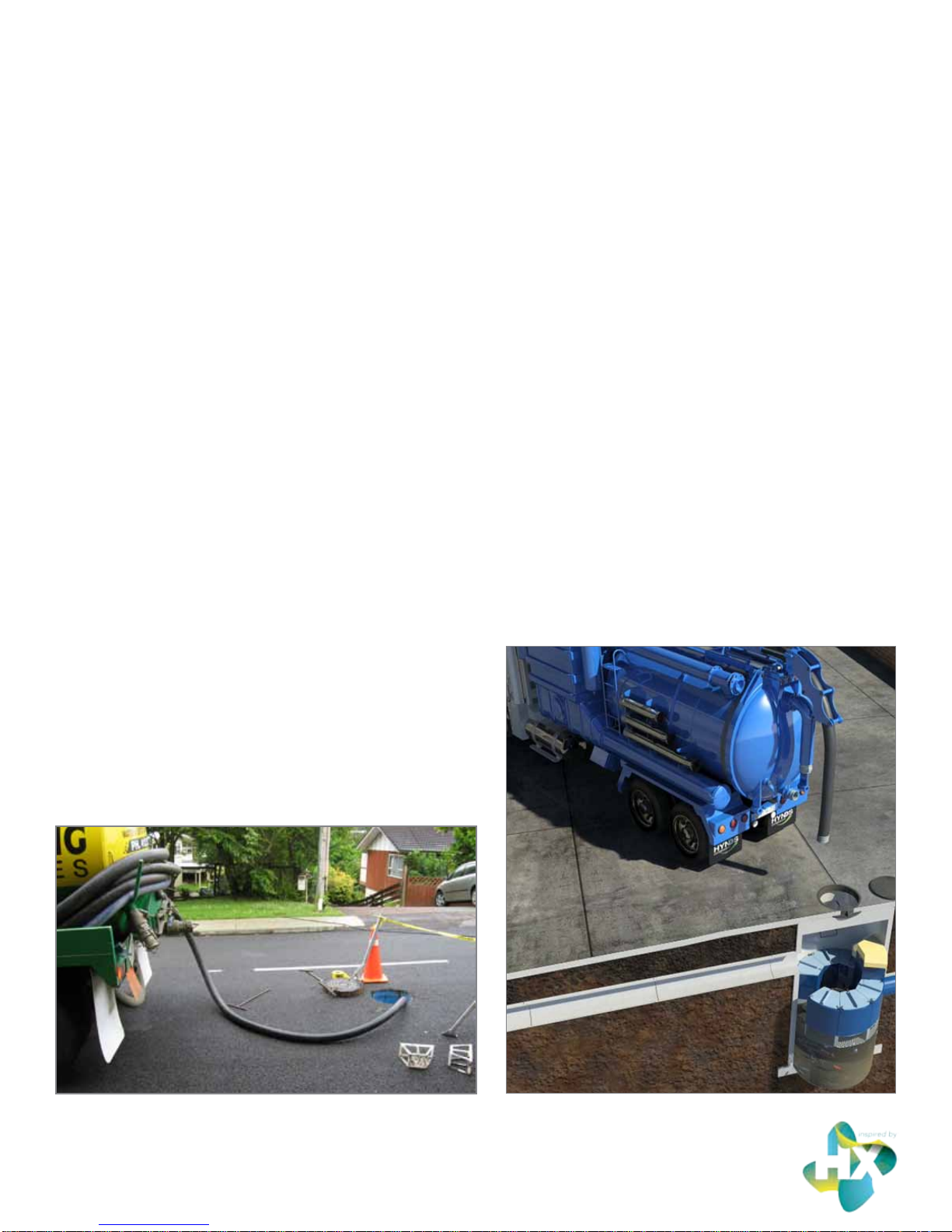

Maintenance Procedures Not Requiring Man Entry:

Floatables, Oil and Sediment Clean Out

1. Set up any necessary safety equipment (such as traf-

c cones) around the access of the Up-Flo®Filter. Safety

equipmentshouldnotifypassingpedestrianandroadtrafc

that work is being done.

2. Remove the grate or lid to the manhole or vault.

3. Without entering the vessel, look down into the chamber to

inspect the inside. Make note of any irregularities.

4. If the standing water level in the sump is above the base of

theFilter Modules(seeFig.8),tugthePullChain(s) tore-

lease the Drain Down Filter plug(s). Allow the excess water

to drain out of the chamber.

5. Use the skimmerpoletottheDrainDownFilterplugback

into the open port.

6.Once all oatables and oil have been removed, drop the

vactor hose to the base of the sump. Vactor out the sedi-

mentandgrossdebrisfromthesumpoor.Upto0.3yd3

(0.2 m3) of sediment and 360 gallons (1,363 L) of water will

be removed from a typical manhole Up-Flo®Filter during

this process.

7. Retract the vactor hose from the vessel.

8.InspecttheAngledScreensforblockagesandragging.If

present, remove the obstruction or ragging materials from

the surface using a hose or other screen-cleaning device.

9. On the Maintenance Log provided by Hydro International,

record the date, unit location, estimated volume of oata-

bles, oils, and gross debris removed, and the depth of sedi-

ment measured. Note any apparent irregularities such as

damaged components or blockages.

10. Securely replace the grate or lid. Remove safety equip-

ment.

11. Dispose of sediment and gross debris following local regula-

tions.

12. Dispose of oil and sump water at a licensed water treatment

facility or following local regulations.

13. Contact Hydro International at (800) 848-2706 to discuss

any irregularities noted during cleanout.

Maintenance Activities Requiring Man Entry

These activities include replacement of the Media Packs and

Drain Down Filter.

Unless the Up-Flo®Filter has been installed as a very shal-

lowunit,itisnecessarytohaveanOSHA-connedspaceentry

trained person enter the vessel to replace Media Packs.

The access port located at the top of the manhole or vault pro-

vides access to the Up-Flo®vessel for maintenance personnel

to enter the vessel and remove and replace Media Packs. The

same access would be used for maintenance personnel working

fromthesurfacetonetorskimdebrisandoatablesortovactor

out sediment, oil, and water. Unless the Up-Flo®Filter has been

installedinaveryshallowconguration,itisnecessarytohave

personnelwithOSHAConnedSpaceEntrytrainingperforming

the maintenance that occurs inside the vessel.

Scheduling

• Call Hydro International to order replacement Media Packs

and Drain Down Filter prior to scheduling maintenance.

• Because Media Pack replacement requires entry into the

Up-Flo®chamber, maintenance events should be scheduled

during dry weather.

• Media Pack replacement should occur immediately after a

contaminated spill in the contributing drainage area.

7

Page | 10

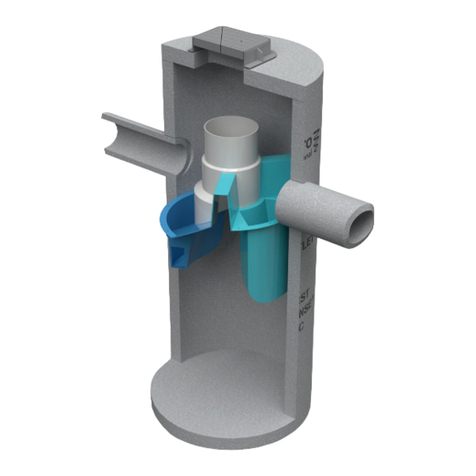

Fig.8 Cutaway view of the Filter Module