Hydrotek Automac Faucets

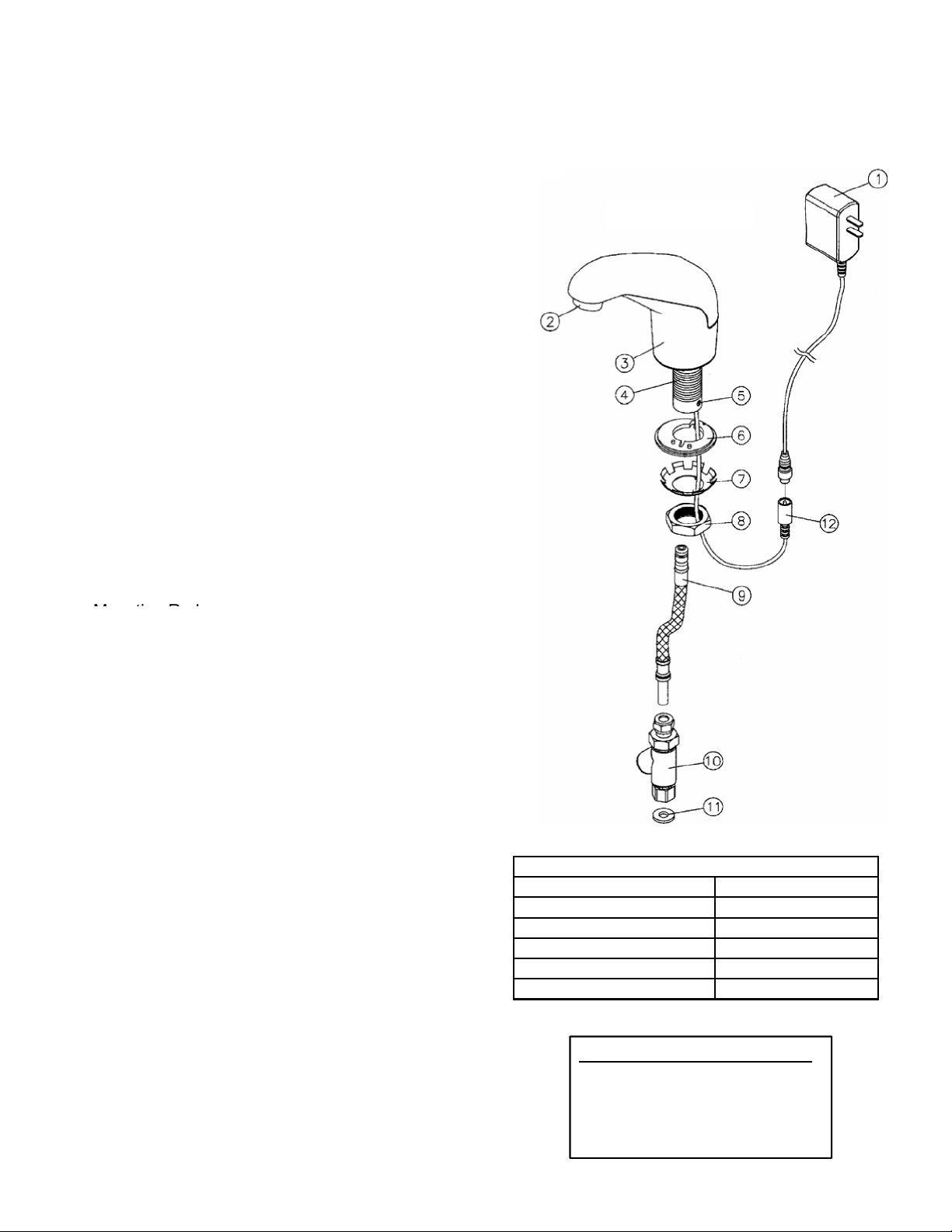

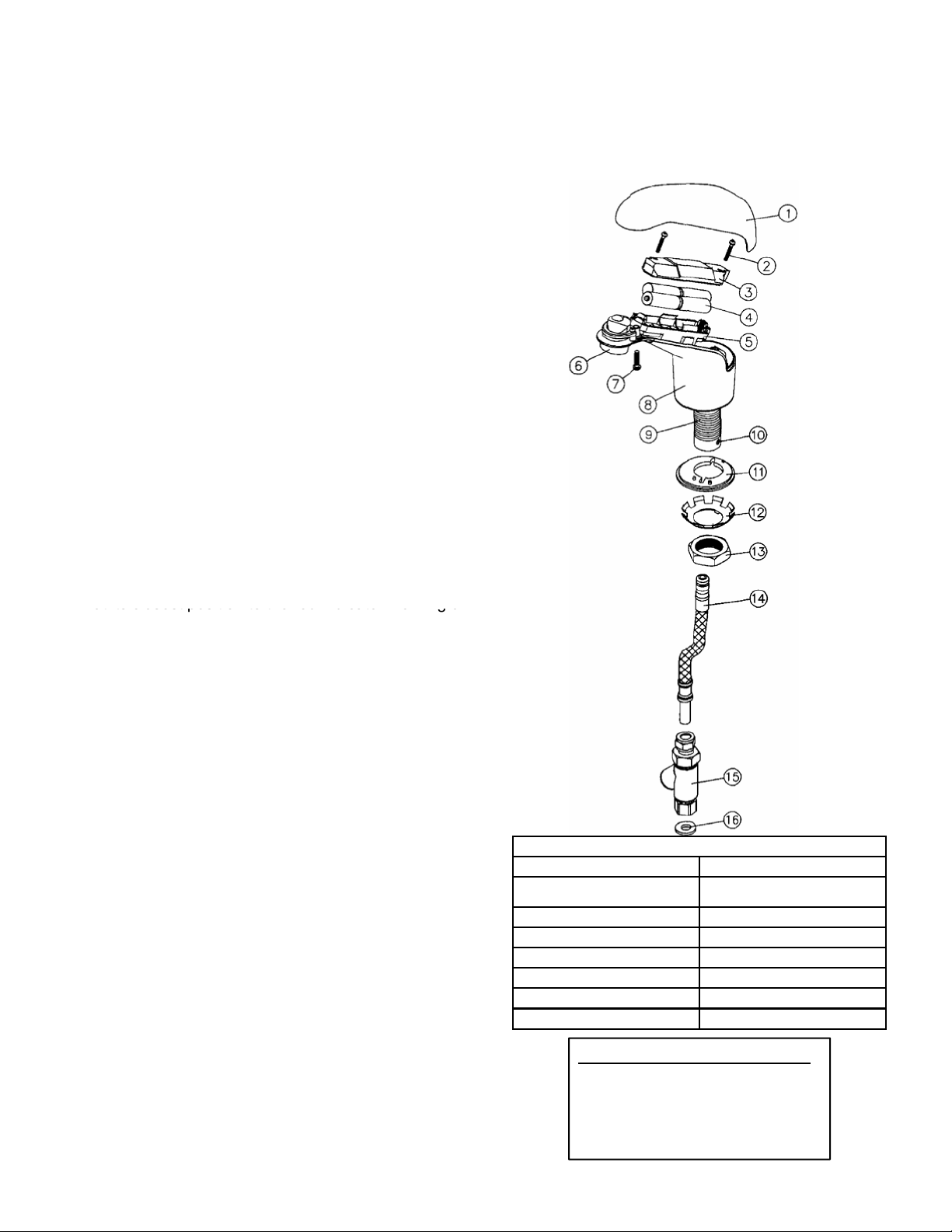

5000E Series

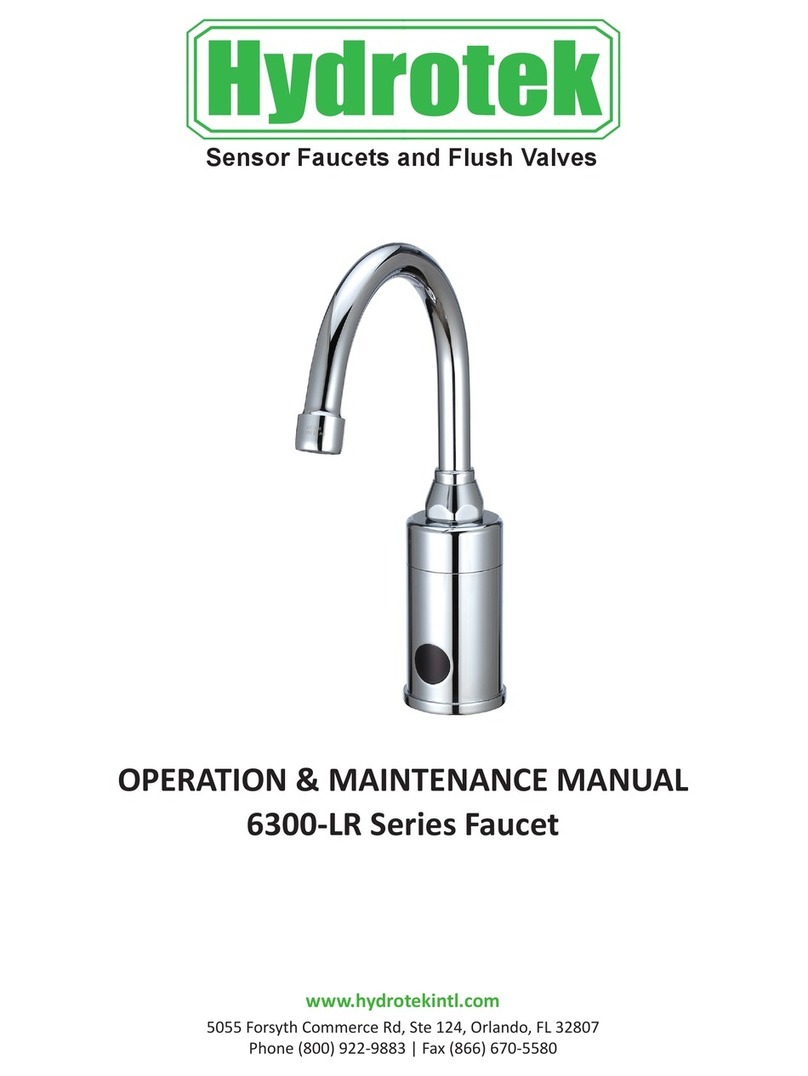

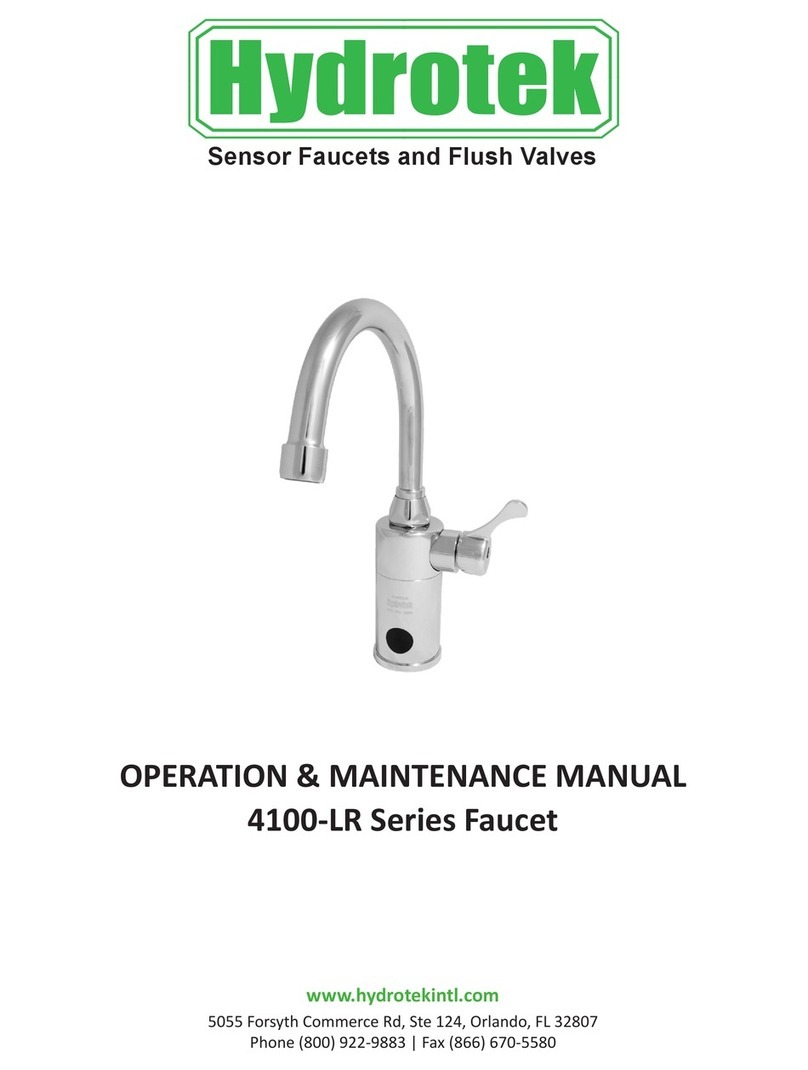

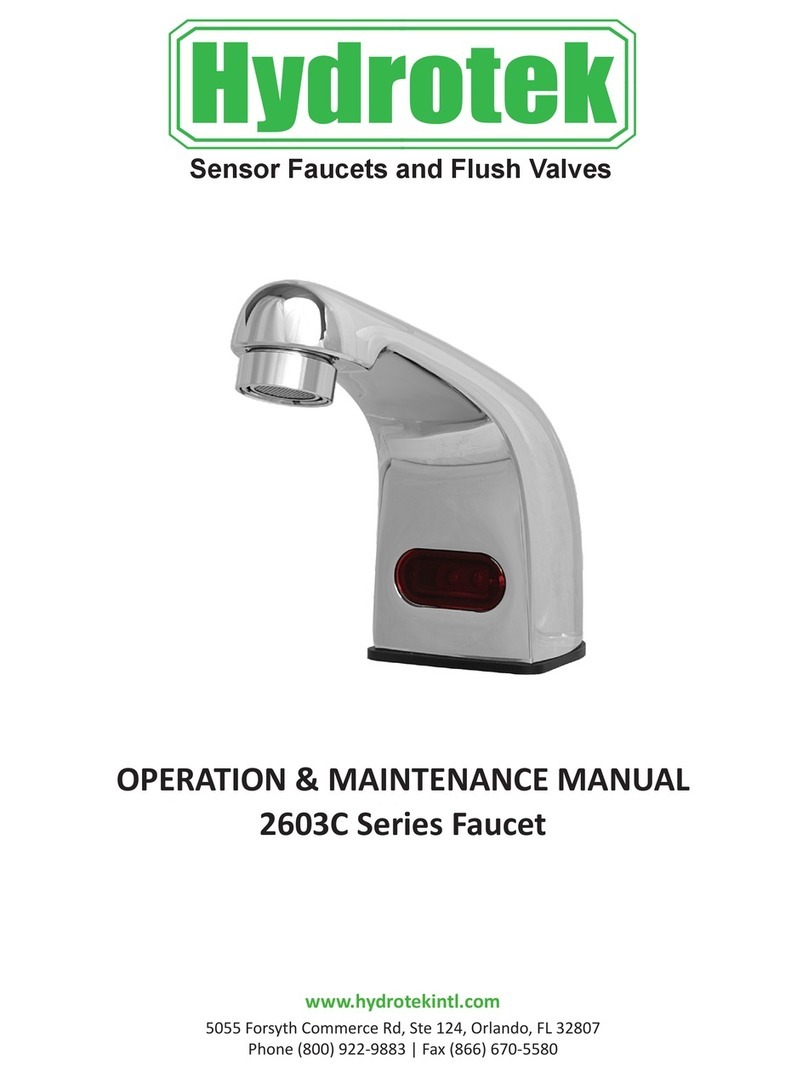

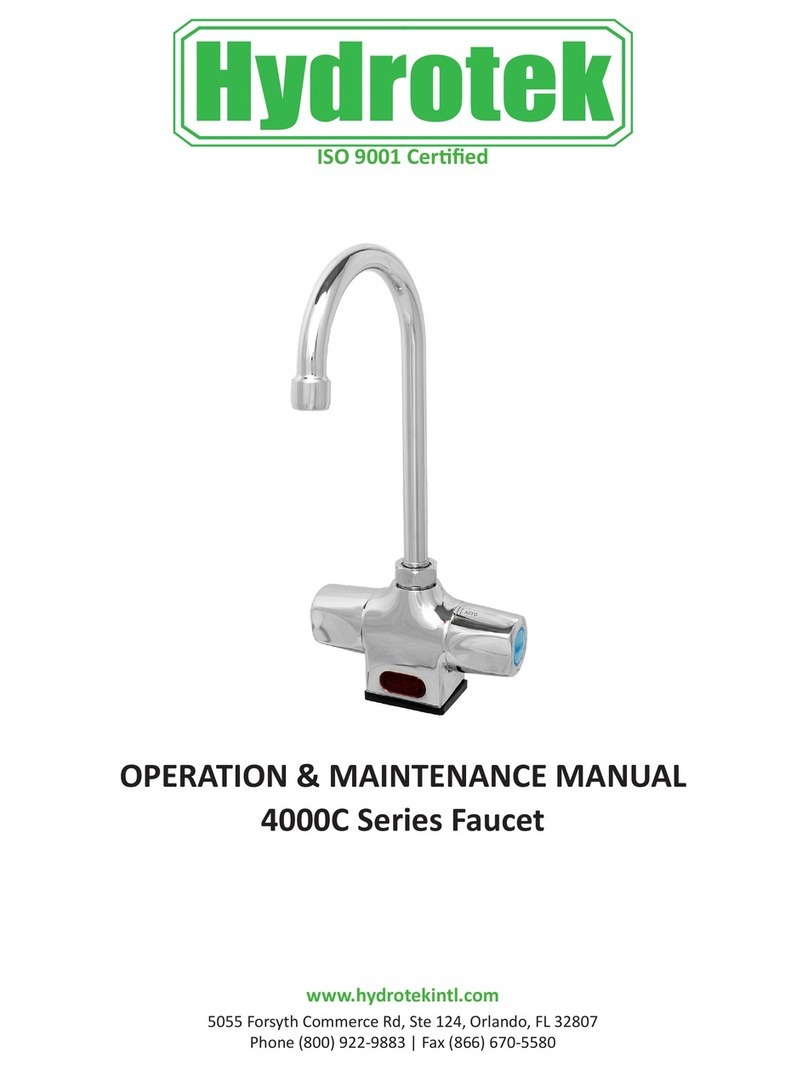

Deck Mounted / Non-mixing

Meets ANSI/ASME A112.18.1 M-1989

Operaon:

1. A connuous, invisible beam is emied from the sensor.

2. The faucet is acvated by placing hands under the spout within the

eecve range of the beam. Water starts to ow immediately for as

long as the user’s hands remain in the sensor range.

3. When hands are removed, the water ow stops. The sensor will

automacally reset and be ready for the next user.

4. In the baery powered version, a ashing red light will indicate a low

baery condion.

Specicaons:

Faucet Construcon: ............... Metal & chrome plated

Control Circuit:

Auto. Time-out: ................. 30 seconds

Sensor Range:................... Self adapng

Shut-o Delay: .................. 1 second

Solenoid Valve: .................... 6V DC, normally closed

Waage: ....................... 0.2W (idle), 3W (in use)

Operang Pressure: ............. 5 psi to 125 psi

Flow Control:...................... 0.5 GPM Laminar, vandal resistant

AC Mode

Power Adapter

Standard Plug-in:.................Input AC 120V 60 Hz

(UL/CSA)......................Output DC 7.5V, 0.8A/Class 2

Power Cable: ................Armored, vandal resistant

Oponal Mul-Unit Adapter: ........Serves up to 8 faucets

(UL/CSA)......................Input AC 120V, Output DC 7.5V, 3A

Baery Mode

Baery Powered Models:............(4) AA Alkaline Baeries

Enduratek Service Life:..............

1.5 million on/o cycles, up to 10 years

Package Includes:

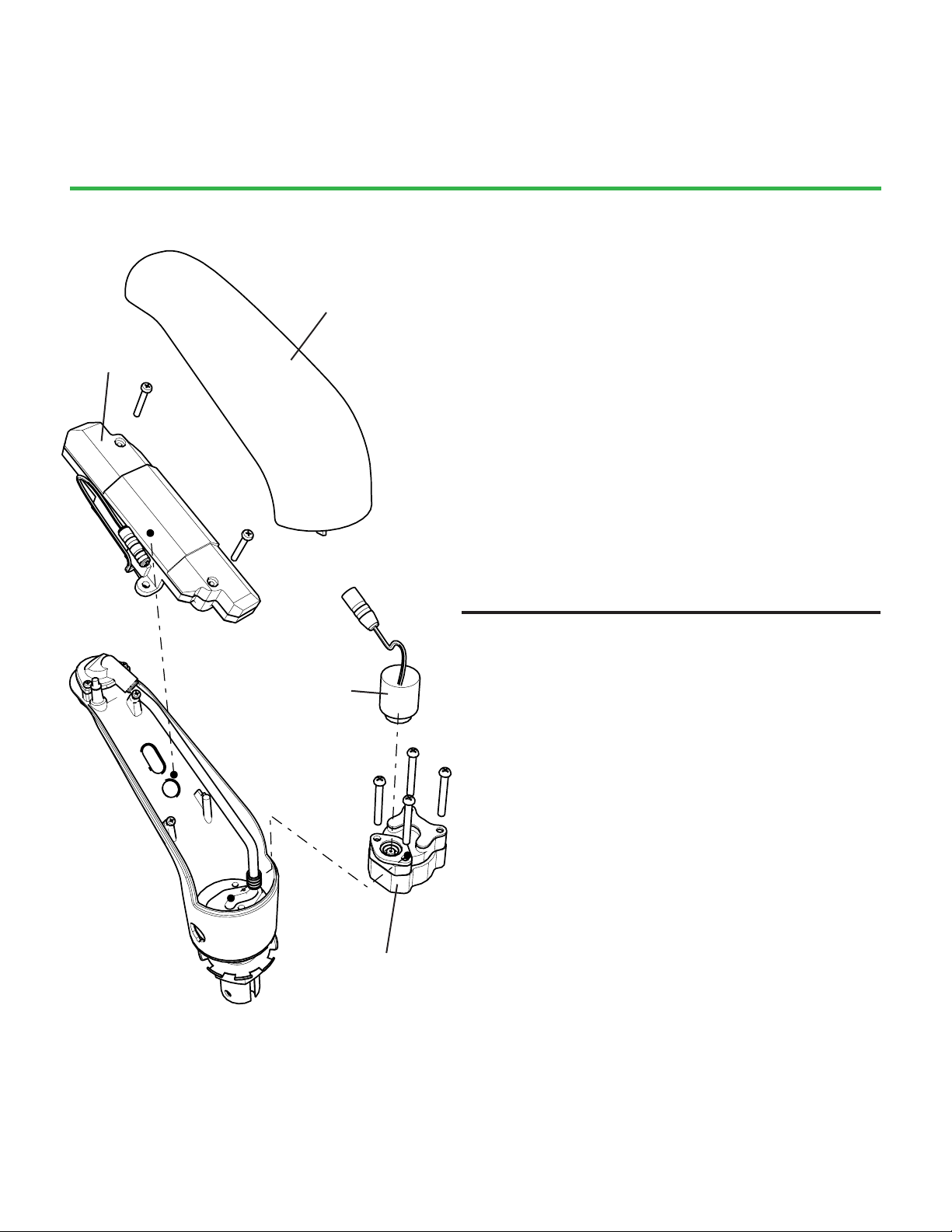

(1) Faucet with sensor/solenoid

(1) 7.5V DC plug-in power adaptor (H-5000E & H-5000E-LR Only)

(2) Armored steel supply tube with lter

(1) Mounng lock nut and washer

(1) 0.5 GPM vandal resistant Rosee ow control

(4) AA Alkaline baeries (HB-5000E & HB-5000E-LR Only)

Dimensions:

Base Width (Outside Measurement) ..................2-3/8”

Base Depth ...................................... 2-3/8”

Faucet Height (Aerator to Base) ..................... 4-7/8”

Faucet Height Overall .............................. 6-1/2”

Depth (Center of Aerator to Center of Faucet Base) ..... 4-7/8”

Mounng Bolt Length.............................. 2-1/4”

Mounng Bolt Size ................................ 1-1/8”

Oponal Variaons and Accessories

• 1.5 GPM VR So Flow or 0.35, 2.2 GPM Laminar Flow Control

• 4” or 8” Centerset Cover Plate

• HC-010E Mul-Unit Voltage Adapter (AC Powered Only)

• HBL-04 Thermostac Mixing Valve with Checks

HYDROTEK INTERNATIONAL, INC.

5055 Forsyth Commerce Rd., Ste 124

Orlando, FL 32807

800.922.9883 (Phone)

866.670.5580 (Fax)

www.hydrotekintl.com

H-5000E (AC Powered)

HB-5000E (Baery Powered)