INSTALLATION INSTRUCTIONS

Hydrotek Model HB/HE-5000EMLR-Mixing Faucet

Battery Powered

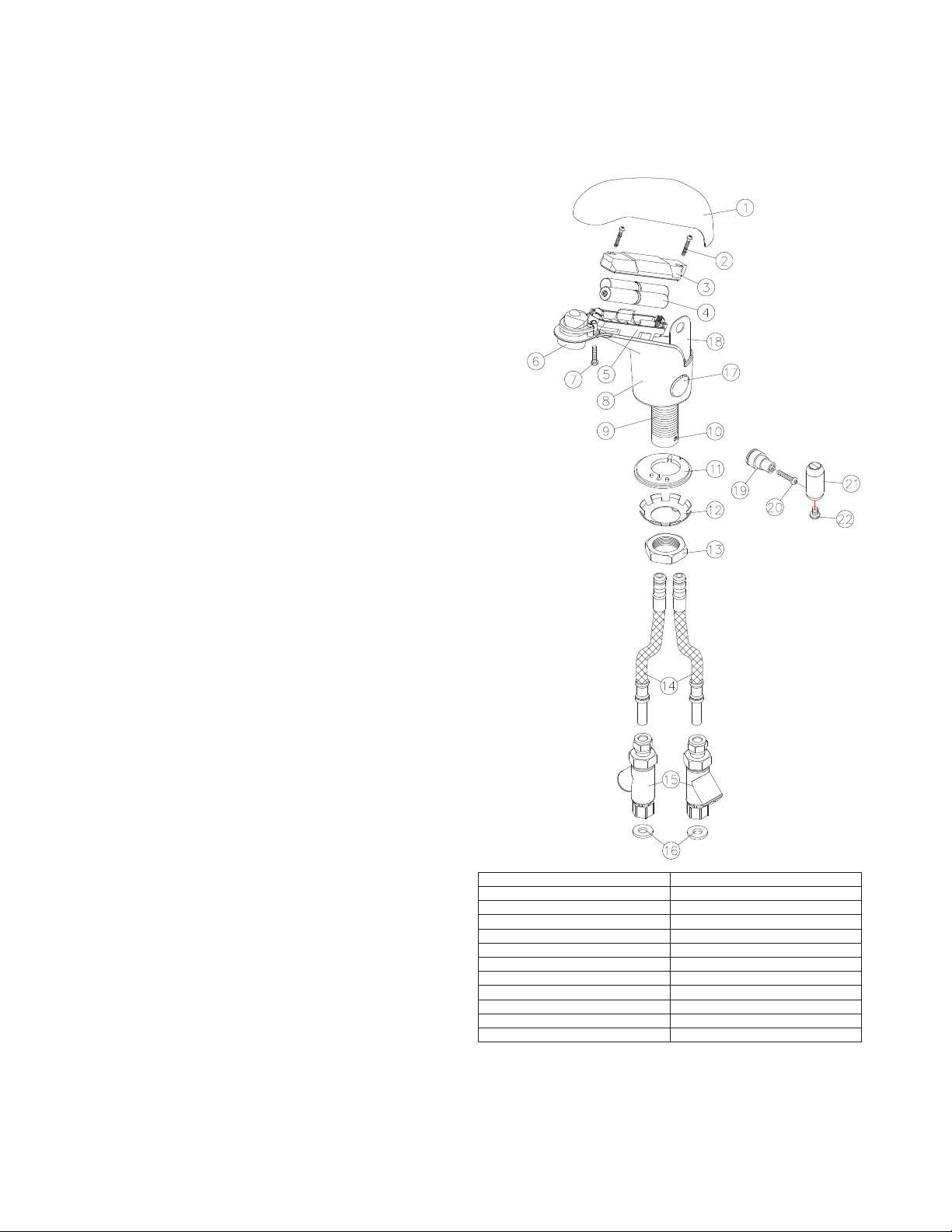

1. Top Cover 12. Star Locking Washer

2. Battery Holder Screws (2)

4. Batteries, AA Alkaline (4)

–

8. Body 19. Mix Shaft Extender

20. Screw, Mix Shaft Extender

10. Locking Screw, Supply Tube

11. Gasket, Rubber 22. Screw, Adjustor Handle

0090H105

0417C

HYDROTEK INTERNATIONAL, INC.

5055 Forsyth Commerce Road, Suite#124

Orlando, FL 32807

1-800-922-9883

866-670-5580(Fax)

Prior to installing this faucet, thoroughly flush all water lines and replace

stop washers as may be required.

Rotate the Supply Tube Locking Screw (10) fully clockwise.Insert both

Supply Tube (14) ends ( with o-rings ) fully into the bottom of the

Mounting Rod (9) by twisting / pushing until properly seated. DO NOT

USE PIPE DOPE, USE TEFLON TAPE. Turn the Locking Screw (10)

counter-clockwise until the markings on the Mounting Rod and the Screw

are properly lined up.

Install in-line Filters (15) onto stop valves using nylon washer (16).

Unscrew Mounting Nut (13) from Mounting Rod (9) and completely

remove both Mounting Nut (13) and Star Locking Washer (12).

From above the deck, carefully feed the Supply Tubes (14) and

Mounting Rod (9) into deck mounting hole and seat faucet in correct

mounting location.

From below the deck, insert the Supply Tubes (14) into the keyed Star

Locking Washer (12) then Mounting Nut (13). Slide Locking Washer

and Mounting Nut up onto Mounting Rod (9) and tighten Mounting Nut

on Mounting Rod to securely lock faucet to the deck.

Connect Supply Tube (14) to the in-Line Filters compression fittings (15)

and securely tighten.

INSTALL BATTERIES and tighten the cover with Battery Holder Screws

(2).You should hear a clicking sound. Dry Test the faucet by placing

hands under the spout and you will hear another clicking sound. If not,

double check the batteries connections and positioning.

Turn water on and check for leaks.

Place your hands under the faucet spout, water should start to flow.

Remove your hands, water should stop. If the faucet is not functioning

properly,RE-INSERT BATTERIES and let the faucet “RESET” itself.

To adjust temperature in internal adjustment mode – open faucet body

top cover and remove Lock-V.R. Access Cover (18) and V.R. Access

Cover (17) from faucet body. With flat-bladed screwdriver rotate shaft

clockwise for colder and counter-clockwise for warmer water.

To install faucet external adjustor handle – open faucet body cover (1)

and remove Lock-V.R. Access Cover (18) and V.R. Access Cover (17)

from faucet body. Install Mix Shaft Extender (19) on Temp. Adjust Shaft

and secure with screw (20).

Securely attach Adjustor Handle (21) to Shaft Extender (19) with

screw (22).

To externally adjust temperature, rotate Adjustor Handle clockwise to

increase, counter-clockwise to decrease water temperature.

To turn faucet on manually – pull Adjustor Handle out from faucet body.

PUSH HANDLE IN toward faucet body to shut off water flow.

IMPORTANT: The stop valve should never be opened to the

point where the water flow exceeds the flow capability of the

fixture. The fixture must always be able to accommodate the

continuous water flow from the valve in the event of a valve

failure. Should the fixture overflow happen due to water

exceeding the capability of the fixture & or the drain pipe,

Hydrotek will not be responsible for any flood damages.

IMPORTANT:This product contains mechanical and/or electrical

components that are subject to normal wear.these components

should be checked regularly (1 year is recommended) and

replaced as needed to maintain the Faucets performance. Call

1-800-922-9883 for furtherdetails.

IMPORTANT:DO NOT use abrasives, acids or cleaning fluids

to clean the Hydrotek Faucet as they may dull the luster and

attack the chrome or special finishes. use only soap and water

then wipe with a clean cloth or towel.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

HE-5000EM

DC Powered Sensor Operated Mixing Faucet

Installaon Instrucons