2

Preparation

Before you leave to do the installation, make sure you have all the equipment needed. Below is a checklist of

what you will usually need. It may be helpful to check each off each thing before you start.

Note: None of the following is supplied with the machine because the parts required vary depending on

the particular installation.

Tools Checklist

1. Toolbox with all common tools.

2. Spade to dig trench (If needed for your installation).

3. Drill with drill bits, hole saws, etc.

Parts Required for Installation

1. 5 gallons fertilizer solution to fill the machine. Note: It will take approx. ½ gallon to prime the machine

before it will start to operate.

2. Four # 12 screws 1 ½” long to mount box to Garage/House (Tap Cons for Concrete, Wood Screws for

Wooden walls, etc.).

3. Silicone sealer to seal mounting screws on machine.

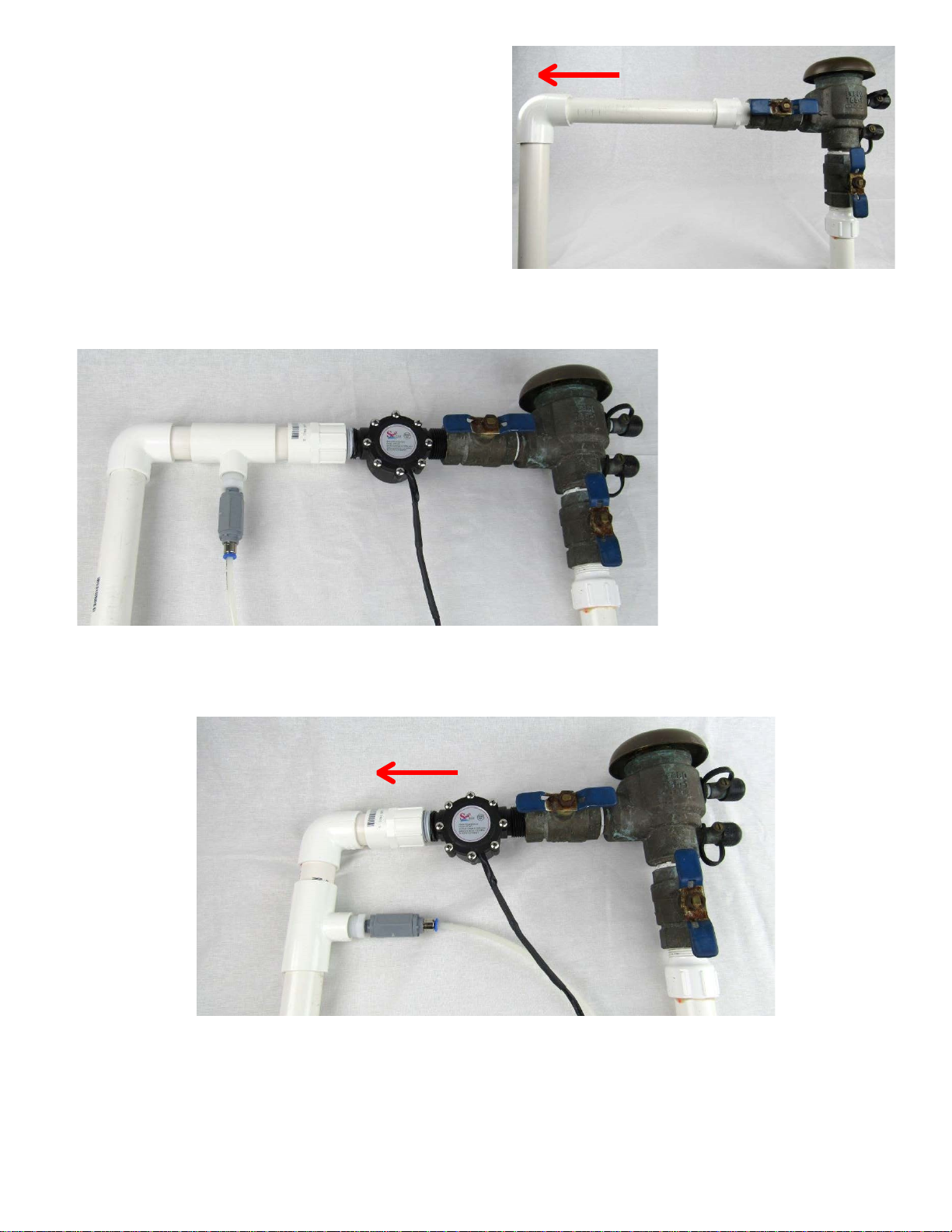

4. Pipe fittings to connect the Flow Sensor and Injection Point into the irrigation system main water pipe

(Included, covered on page 4)

5. Pipe Sealing Compound to seal the pipe fittings for Flow Sensor.

6. Clips to attach tubing to the side of the Garage/House.

7. Optional: ½” conduit to protect tubing if tube is to run in a position where it could be damaged (not

included but available at Home Depot or Lowes).

Performing the Installation

Note: Before you start, it’s a good idea to mentally go through the whole job making sure that you have everything you

need to complete the whole installation process.

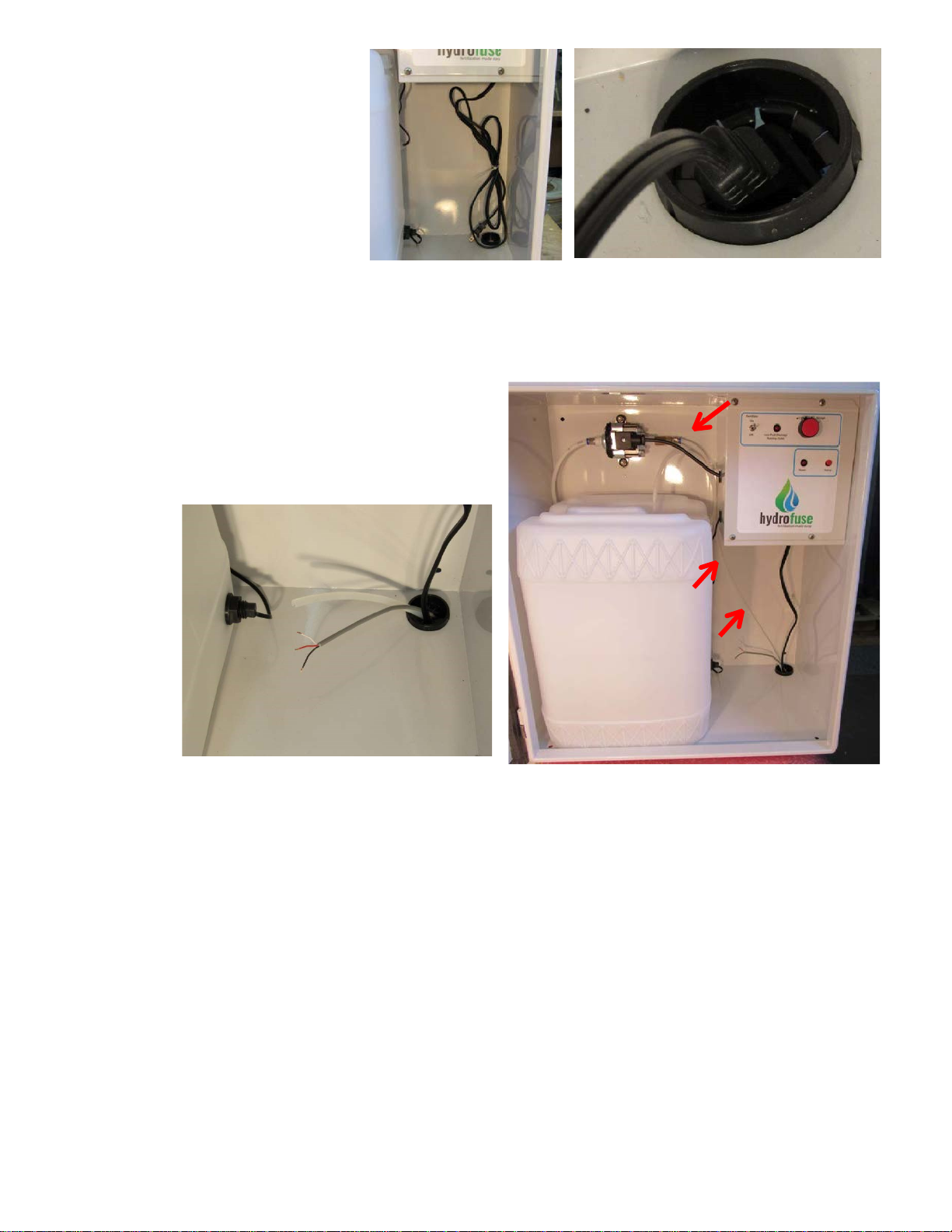

1. Location for the Machine. Pick a good location where you will easily be able to run the injection tubing,

Flow Sensor, and also a 120 V power outlet to plug the system into.

2. Mount to the wall using four 1 ½” long # 12 screws. Use appropriate screws for the material the wall is

made of - wood or masonry. Choose a height that is good for your customer so they can easily operate the

system and use a level to ensure the machine is not at an angle. Tip: If desired the box can be painted to

match the color of a house.

3. Seal the Screws with a small amount of silicone sealer to ensure water does not enter the enclosure.