6

Operating Instructions

NOTE: For proper low water cut-off operation, the boiler should be

cleaned at initial installation and periodically thereafter. Refer to the

boiler manufacturer’s instructions for cleaning procedures.

OPERATING TEST PROCEDURE

1. After installation, bring the boiler water to a safe operating level,

turn on power and set the thermostat to call for heat. The amber

LED lamp should be off. The boiler will fire immediately.

2. Slowly lower the boiler water to a point below the probe. The

amber LED lamp on the control will light. The lamp may begin to

flicker with the bouncing water level. Stop draining the boiler

when the lamp glows steadily.

NOTE: The water should not be lowered beyond a visible point in

the gauge glass.

3. The boiler will shut down within 15 seconds.

IF BURNER DOES NOT SHUT DOWN IN LOW WATER

1. Check to see if a foaming condition in the boiler is preventing the

control from accurately detecting the water level. With power to

the system on, and water above the probe level, set the thermo-

stat so there is no call for heat and allow the burner to shut

down. Then, slowly lower the water in the boiler to a point below

the probe. The amber LED lamp should turn on and the relay will

open after a 15 second delay. Once this has occurred, reestablish

a call for heat and the boiler should not fire. Now raise the water

level to an operating level. The amber light should turn off and

the control should reenergize the burner circuit after a 30 second

delay. If the control functions normally during this test, but allows

water to drop below the level of the probe when the test is con-

ducted with the burner on (as described in the Operating Test

Procedure above), the boiler is foaming. The CycleGard provides

protection for foaming boilers (see CycleGard Intermittent Level

Test Feature on page 5). However, to provide optimal steaming

performance, it is still recommended that you clean the boiler in

accordance with the manufacturer's instructions. The foaming

condition is caused by machining oils, elevated mineral content

from make-up water, grease and other contaminants in the boiler

water. Cleaning the boiler will eliminate foaming conditions in the

boiler and provide for optimal steaming performance.

2. Check terminal block wiring to insure that all connections are

correct.

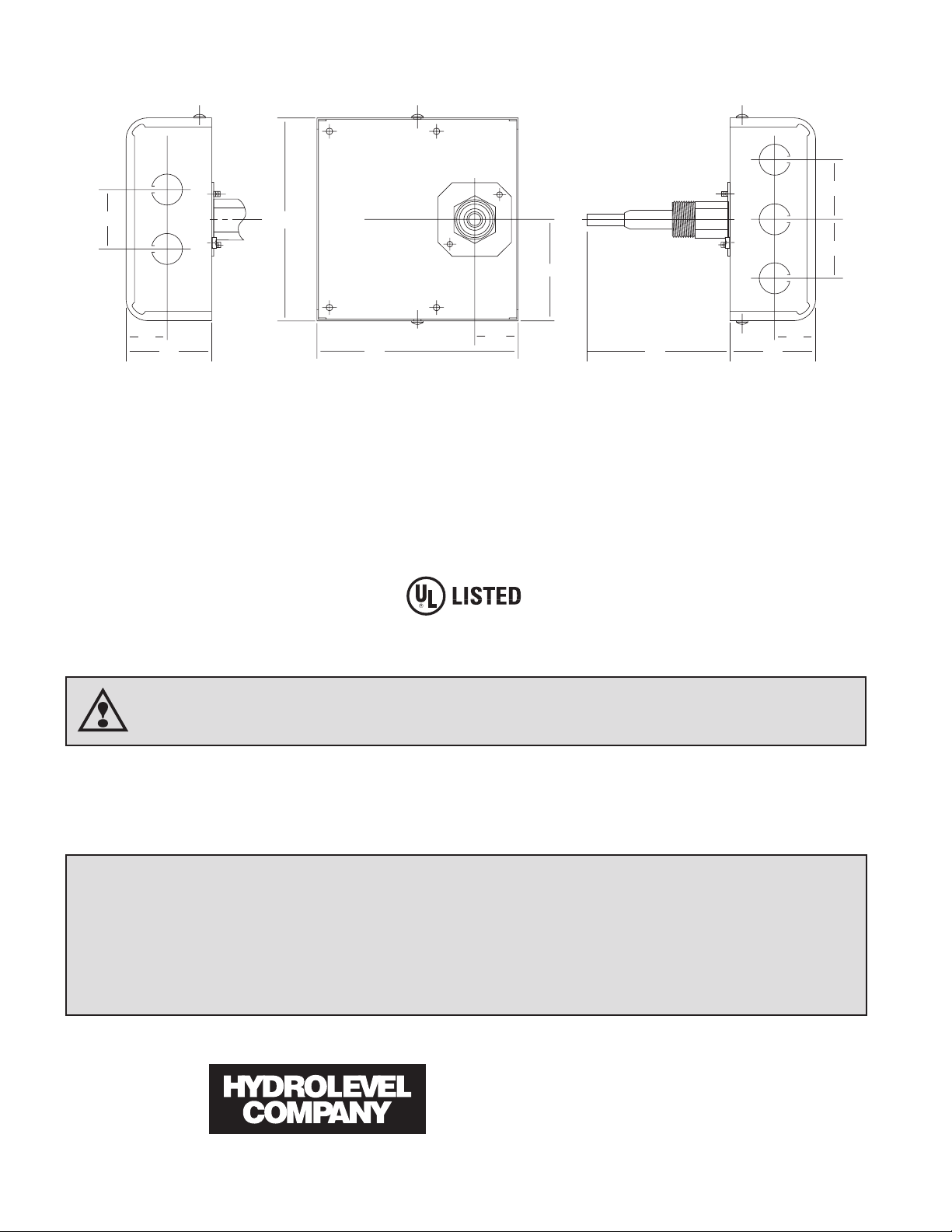

3. Check the probe installation to insure that there is 1/4" clearance

from any surface within the boiler or pipe. (Refer to Step 3 on

page 1 of this instruction sheet.

IF THE AMBER LED LAMP IS ON

The amber LED lamp indicates that the water is below the probe. If

the gauge glass shows that the water is at the correct operating

level and the amber LED is lit check the following:

1. Check for plugged gauge glass.

2. Make sure probe lead wire is properly secured to the terminal.

3. Check for proper ground between probe and boiler shell.

Excessive use of Teflon tape or sealing compound may isolate the

probe from the boiler shell.

4. Remove probe and examine for oily residue. Clean probe with

steel wool and skim boiler.

IF THE GREEN LED LIGHT IS ON

The green LED lamp indicates that the control is conducting an

Intermittent Level Test. The burner does not fire during the test peri-

od. See Intermittent Level Test Feature on page 5 for more details.

Maintenance

To insure optimum performance, remove and inspect the probe

annually.

Clean any sediment or scale from the probe using a scouring pad or

steel wool.

NOTE: Do not use caustic chemicals that could damage the

probe.

Reinstall the probe and perform the Operating Test Procedure

described above.