6

SYSTEM CONFIGURATION

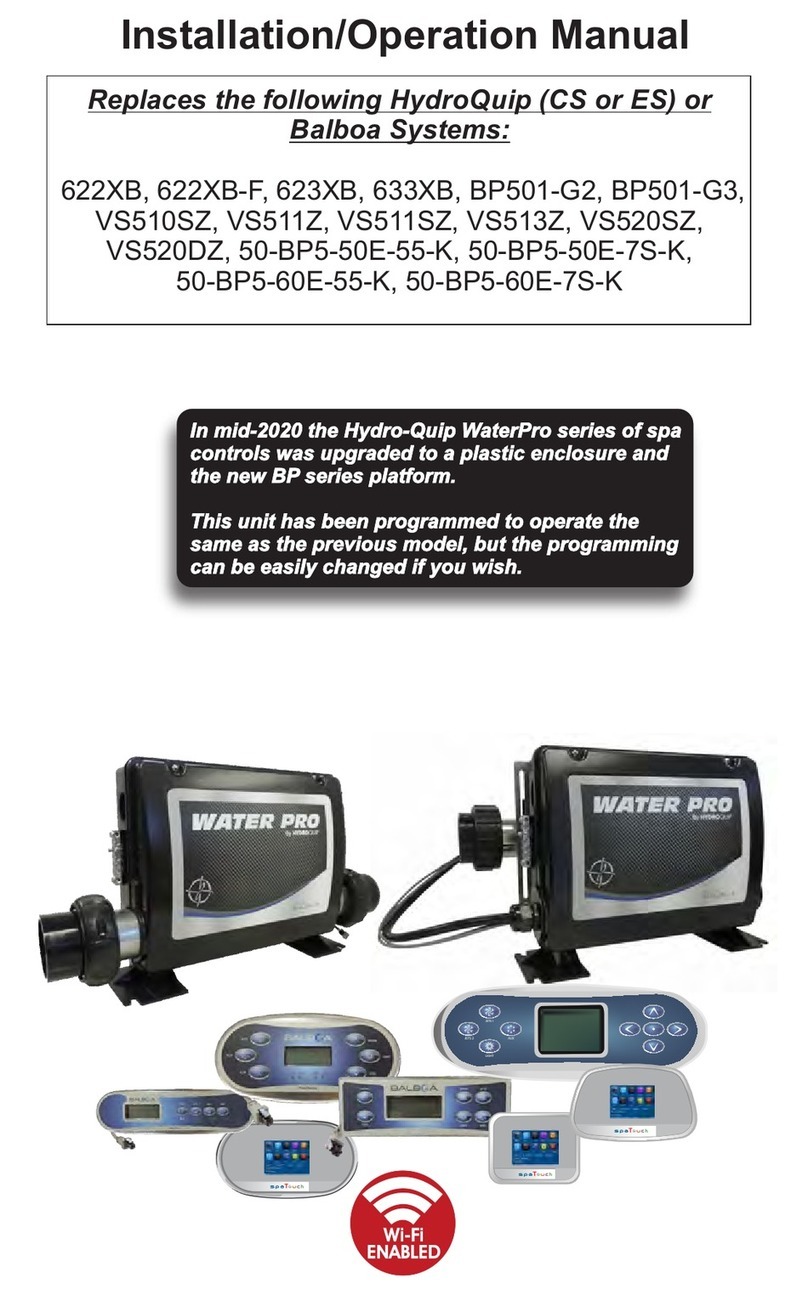

Congratulations on your purchase of the Universal Series Control System from Hydro-Quip. This

series of controls has been developed to allow you complete flexibility during your installation.

This Control System is configured to allow you to choose the voltage for each circuit at the time

of installation. We highly recommend that all component cords be replaced at the time of

installation.

The Universal conversion procedure MUST be accomplished PRIOR to connecting input

service wiring. This control has been shipped from the factory with ALL circuits wired for

120 VAC.

VERIFY YOUR COMPONENT VOLTAGE REQUIREMENTS: 120 VAC will not harm a 240 VAC

component if operated temporarily. 240 VAC WILL harm a 120 VAC component almost

immediately. This is the reason we ship all circuits in the 120 VAC configuration. Hydro-Quip

cannot be held responsible for mis-wire related damage to components.

Note: To utilize the Universal circuitry (120/240VAC), incoming service must be 240V/4-Wire.

Hydro-Quip has made the conversion process simple and easy. After you have

determined the voltage of your components (pump(s), air blower, ozonator etc.), you are

now ready to complete the conversion process. Color-Coded Neutral Wire connectors

have been provided to easily distinguish the circuit to be converted. By simply moving a

Neutral wire from the Neutral side of the conversion terminal block, clearly marked and

located inside the control enclosure, to the Line 2 side completes the circuit conversion.

Follow the illustrations and step-by-step instructions.

Step 1

Circuit Color Chart

Red Connector = Pump 1 Brown Connector = Circulation Pump

(Optional)

Violet Connector = Pump 2 (Optional)

Note: Ozonator Circuit 120V ONLY

Blue Connector = Air Blower

Remove 2(ea) screws and open

front cover of enclosure. Locate

the conversion terminal block and

desired connector (using ‘Circuit

Color Chart” above). Carefully

remove connector from the Neutral

side.

Li e2

ner

l

t

Nua

0oot

m

4p

n

e

(s)

2V

C n pn

(2e s

Vo

10 C n)

ot

m

If you have a 3-wire/240V connected

system, you will not have the Universal

option

!

!

!