TECSYSTEM NT935 WS User manual

2

NT935 WS

PAGE

1) SAFETY REQUIREMENTS

………..........................................

4

2) ACCESSORIES

…………………………………..

5

3) TECHNICAL SPECIFICATIONS

…………………………………..

6

4) FRONT PANEL

…………………………………..

8

•DISPLAY

…………………………………..

9

•OPERATING PROGRAM CONTROL

………………………………….

—

•NOTES ON SCAN AND MAN FUNCTIONS

…………………………………..

—

•LED TEST

…………………………………..

—

•ALARM RELAY TEST

…………………………………..

—

•ALARM RELAY SILENCING

…………………………………..

—

5) MOUNTING

…………………………………..

10

6) ELECTRICAL CONNECTIONS

…………………………………..

11

•NT935 WS BACK

…………………………………..

—

•POWER SUPPLY

…………………………………..

12

•ALARMS AND VENTILATION

…………………………………..

—

•FAULT AND RESET MESSAGE SEQUENCE

…………………………………..

—

7) PROGRAMMING

…………………………………..

13

•NT935 WS

…………………………………..

—

•PROGRAMMING NOTES

…………………………………..

14

•TEMPERATURE SENSORS

…………………………………..

15

•MEASUREMENT SIGNAL TRANSFER

…………………………………..

—

•TEMPERATURE SENSOR DIAGNOSTICS

…………………………………..

16

•VOTING FUNCTION

…………………………………..

—

•PROGRAMMED DATA DIAGNOSTICS

…………………………………..

—

•TEMPERATURE DIAGNOSTICS

…………………………………..

—

•COOLING FAN CONTROL

…………………………………..

17

•FAN TEST

…………………………………..

—

•INTELLIFAN FUNCTION

………………………………….

—

INTRODUCTION

CONTENTS

First of all we wish to thank you for choosing to use a TECSYSTEM product and recommend you read this instruction

manual carefully: You will understand the use of the equipment and therefore be able to take advantage of all its functions.

ATTENTION! THIS MANUAL IS VALID AND COMPLETE FOR THE NT935 WS CONTROL UNIT

3

NT935 WS

PAGE

8) FAIL SAFE FUNCTION

…………………………………..

18

9) TECHNICAL SPECIFICATIONS OF THE EXTENSION CABLE

FOR Pt100

…………………………………..

—

10) FCD FUNCTION

…………………………………..

19

11) NT935 WS WIFI CONNECTION

…………………………………..

—

12) TECSYSTEM WEB SERVER

…………………………………..

21

•WEB SERVER MANAGEMENT BAR

…………………………………..

22

•HOME SCREEN

…………………………………..

—

•SETTINGS SCREEN

…………………………………..

23

•NETWORK SETTINGS

…………………………………..

24

•OPTIONS

…………………………………..

25

•GRAPHICS SCREEN

…………………………………..

26

•EVENTS SCREEN

…………………………………..

27

•GRAPHIC VIEW NOTES

…………………………………..

28

•EXPORT NOTES CSV FILE

…………………………………..

—

•PIN CODE

…………………………………..

—

13) TROUBLESHOOTING

…………………………………..

29

14) WARRANTY CONDITIONS

…………………………………..

—

15) EQUIPMENT DISPOSAL

…………………………………..

30

16) USEFUL CONTACTS

…………………………………..

—

17) NT935-4 WS NOTES

…………………………………..

—

18) UL SPECIFICATION AND RATING

…………………………………..

31

4

NT935 WS

SAFETY REQUIREMENTS

ATTENTION:

Carefully read the manual before starting using the control unit. Keep the instructions for future reference.

Do not open the device, touching any internal component can result in electric shock as voltages over 50 volts

can be lethal. In order to reduce the risk of electric shock, do not disassemble the back of the device. Warranty shall be

void if device is opened.

Before connecting the device to the power supply, ensure that all the connections are correct. Always disconnect

the unit from the supply before making any modification on the wiring.

Any operation on the equipment must be operated by a qualified technician.

Failure to comply with these instructions can cause damages, fires or electric shock, and possible serious injuries!

POWER SUPPLY

The NT935 WS can be supplied from 85 to 260 Vac-Vdc, irrespectively of polarity in Vdc. Before use, ensure that the power

cable is not damaged, knotted or pinched. Do not tamper with the power cable. Never disconnect the unit by pulling the

cable, avoid touching the clamps. Do not carry out any connecting/disconnecting operation with wet hands. To disconnect

the device, do not use objects such as levers. Immediately disconnect the device if you smell burning or see any smoke:

contact technical service.

LIQUIDS

Do not expose the equipment to liquid spurts or drops, do not position it in places where humidity exceeds 90% and never

touch it with wet or humid hands. If any liquid penetrates the control unit, disconnect immediately and contact technical

service.

CLEANING

Disconnect the power cable before cleaning the control unit, using a dry cloth without any solvent or detergent, and

compressed air.

OBJECTS

Never insert objects into the openings of the control unit. If this happens, disconnect the control unit and contact technical

service.

USE RESERVED TO QUALIFIED PERSONNEL

The purchased good is an advanced electronic device that should not be used by non-qualified personnel. Any operation

must be carried out by a qualified technician.

ACCESSORIES

The use of non-original accessories or spare parts may damage the unit and endanger users' safety. In event of fault,

contact technical service.

LOCATION

Install the control unit indoor, in a place protected from water splashes and sun rays. Do not place near heat sources if

exceeding the parameters stated in this manual. Position on a stable surface, far from any possible vibrations. Position the

unit as far as possible from intense magnetic fields.

REPAIRS

Do not open the control unit. In case of fault, always contact qualified personnel. The opening of the control unit and/or the

removal of the series identifying label automatically make the warranty void. The warranty seal is applied to all devices,

any attempt to open the unit would cause the seal to break the consequent automatic cancellation of the warranty.

FUNCTION

To control the transformer correctly from a temperature point of view, enabling the VOTING function is allowed

where the load distributed between the phases of the transformer is adequately balanced.

TECHNICAL INFORMATION

Mail: ufficiotecnico@tecsystem.it —tel: 02/4581861

5

NT935 WS

The following objects are present inside the box:

Control unit

Start guide and QR code

2 blocks for panel mounting

1 supply terminal 3 poles pitch 5

Code: 2PL0367 - Screws tightening torque 0.5Nm

1 relay terminal 12 poles pitch 5

Code: 2PL0361 - Screw tightening torque 0.5Nm

1 Pt100 sensors terminal 12 poles pitch 3.81

Code: 2PL0420 - Screws tightening torque 0.25Nm

1 external Wi-Fi SMA Antenna

ACCESSORIES

ATTENTION: always install the device using the terminals included in the pack.

The use of terminals other than those included with the control unit might cause malfunctions.

6

NT935 WS

TECHNICAL SPECIFICATIONS

NT935 WS

POWER SUPPLY

Supply rated values

85-260 Vac-Vdc

50/60HZ

Vdc with reversible polarities

●

INPUTS

4 inputs for RTD sensors, Pt100 type with 3 wires (max section 1.5mm²)

●

Connections on removable terminal strips

●

Input channels protected against electromagnetic interference

●

Cable compensation for thermistors

500m (1mm²)

OUTPUTS

2 alarm relays (ALARM AND TRIP) SPDT

●

1 sensor or operating failure (FAULT) relay SPST

●

2 ventilation management relays (FAN 1 and FAN 2) SPST

●

Output relays with 10A-250Vca-res COSФ=1 contacts

●

Wi-Fi Connection: protocol 802.11 b/g/n , frequency 2.4 GHz with removable external antenna

Max 100m

in open field

DIMENSIONS

100 x 100 mm DIN 43700 dept 150 mm (including antenna - installed at 90° - and terminal

board)

Hole 92 x 92 mm

TESTS AND PERFORMANCE

Construction in compliance with CE regulations

●

Protection from electrical interference EN 61000-4-4

●

Dielectric strength 1500 Vac for a min. between output relays and sensors, relays and power

supply, power supply and sensors

●

Accuracy ±1% vfs, ±1 digit

●

Ambient operating temperature from –20°C to +60°C

●

Humidity 90% non-condensing

●

Frontal film polycarbonate IP65

●

7

NT935 WS

TECHNICAL SPECIFICATIONS

NT935 WS

Housing NORYL 94 _V0

●

Absorption 7.5VA

●

Digital linearity of sensor signal

●

Self-diagnostic circuit

●

Protection treatment of the electronic part

Option

DISPLAY AND DATA MANAGEMENT

2 x 13 mm displays with 3 digits to display temperatures, messages and channels

●

3 LEDs to display the state of the alarms of the selected channel (ALARM-TRIP-FAULT)

●

4 leds selection of display mode (SCAN-AUTO-MAN-T-MAX)

●

2 LEDs to display the state of FAN1 and FAN2

●

Temperature control from 0°C to 240°C (*)

●

2 alarm thresholds for channels 1-2-3 (**)

●

2 alarm channels for channel 4 (**)

●

2 ON-OFF thresholds for FAN 1 and FAN 2

●

Sensor diagnostics (Fcc-Foc-Fcd)

●

Data memory diagnostics (Ech)

●

Access to programming through front keyboard

●

Automatic exit from programming, display and and test after 1 minute's inactivity

●

Incorrect programming warning

●

Selection between channels automatic scanning, hottest channel or manual scanning

●

Storage of maximum temperatures reached by channels and alarm status

●

Front key to reset the alarms

●

Voting Function

●

Intellifan function

●

Fail Safe Function

●

WEB SERVER Wi-Fi Function

●

Synchronization with SERVER NTP (Network Time Protocol) in STATION mode

●

(*) On demand, available version from -40°C to 200°C with alarm temperature management range from 0°C to 200°C

(**) 4 CH channels with independent programming are available on request, see notes NT935-4 WS.

8

NT935 WS

1)

3-digit temperature display

12)

Enter/Reset button

2)

Control unit series

13)

Programming/Setting key

3)

TRIP (red) LED

14)

Led/relay test key

4)

ALARM (yellow) LED

15)

RS (green) LED

5)

FAULT (red) LED

16)

3-digit channel display

6)

FAN 1 (yellow) LED

17)

T-max mode selection (red) LED

7)

FAN 2 (yellow) LED

18)

Man mode selection (yellow) LED

8)

Display mode selection key

19)

Auto mode selection (green) LED

9)

Fixing block

20)

Scan mode selection (yellow) LED

10)

UP key

21)

Fixing block

11)

DOWN key

FRONT PANEL

1

2

3

4

5

6

7

8

9

10

11

12

14

13

15

16

17

18

19

20

1MN0157 REV.0

21

9

NT935 WS

DISPLAY

The first display is dedicated to temperatures.

The second display to the monitored channel.

When the device is switched on or after a reset, the model of the NT935 control unit, the type of sensors, VER "00" (firmware

version, the temperature range of the device and the WS (web server) identification are always shown on the display.

Pressing the MODE key, the display modes can be set:

•SCAN: the monitoring unit displays all the activated (°C) and deactivated (NO) channels scanning every 2 seconds.

•AUTO: the monitoring unit displays the hottest channel automatically.

•MAN: manual reading of the channel temperature using the up/down keys

•T.MAX:The display shows the maximum temperature of the channel selected with the cursor keys. In the event of fault,

the Tmax value is replaced with the type of fault stored (fcc-foc). Turning ON of the leds Trip-Alarm-Fault LEDs alerts us to

events that have occurred. The stored values are always successive to the moment of the last T-MAX reset, for resetting

the values press the RESET key.

OPERATING PROGRAM CONTROL

To control the protection levels programmed, press the PRG key twice to access the VIS programme. Repeatedly pressing

the PRG key, you can scroll through all the previously loaded values in sequence.

After 1 minute's keyboard inactivity, the programming display procedure is automatically abandoned.

To stop the display, press the ENT key.

NOTES ON SCAN AND MAN FUNCTIONS

During the SCAN and MAN modes, the operation of the NT935 can be displayed.

1) RUN cPU:

This message appears when the device is turned on.

2) Ech Err:

This message appears when a damage in the EEPROM memory is detected.

Pressing Reset will cancel the message and restore the original default parameters, listed in the programming paragraph

on pages 13-14. Return the control unit to TECSYSTEM for repairs.

3) CAL Err:

This message appears when damage is found in the measurement circuit.

The temperature values displayed might be incorrect. Return the control unit to TECSYSTEM for repairs.

4) Pt Err:

This message appears when it is detected that one or more PT100 sensors are not working correctly, FOC, FCC and

FCD indications in the temperature sensor diagnostics paragraph on page 16. In case of Err the FAULT relay will be

de-energised.

The above messages will be displayed following the 1-2-3-4 priority stated.

NOTE: in any display mode in case of faulty sensor failure (fcc, foc or fcd) the control unit will automatically set up in SCAN

mode (PRIVILEGED SCAN) allowing immediately displaying of the fault condition on the relative CHn channel (the Mode

key is disabled ).

LED TEST

We suggest carrying out the control unit LED test regularly.

For this operation, press the TEST key briefly; all the displays turn on for 2 seconds.

If one of the LEDS does not work, please return the control unit to TECSYSTEM for repair.

ALARM RELAY TEST

This function allows you to carry out a test of the relay operation without having to use further devices. To start the test

procedure, press and hold the TEST button for approximately 5 seconds: the TST indication appears for 2 seconds confirming

entry into the Relays Test mode.

L The LED that is lit shows the relay to be tested; use the cursors to select the desired relay.

Press the SET and RESET keys to energise and de-energise the relay to be tested; the display will show ON-OFF.

After 1 minute's keyboard inactivity, the RELAY TEST procedure will be automatically abandoned.

To stop the RELAY TEST procedure, press the TEST key.

Alternatively it is possible to use the PT100 model simulator: SIM PT100.

ATTENTION: accessing at the relay test mode will temporarily disable the failsafe function, the relays with function

enabled switch (ALARM-TRIP-FAULT).

ALARM RELAY SILENCING

If you want to silence the ALARM signal press the RESET key: the relay de-energises and the ALARM LED, which was fixed,

will start flashing. Silencing is automatically disabled when the temperature goes below the ALARM threshold.

10

NT935 WS

Fix the unit securely with the blocks supplied.

Connect the Wi-Fi antenna only after suitably fixing the device.

1)

Control unit

2)

Panel hole dimensions (+0.8 mm tolerance)

3)

Identification label

1)

Control unit

3)

Fixing screw

2)

Fixing blocks

4)

Cross-head screwdriver #1X100mm

MOUNTING

1

1MN0007 REV. 0

2

3

1

2

3

4

1MN0008 REV. 0

Drill a 92 x 92 mm hole in the panel sheet.

11

NT935 WS

NT935 WS

SCREEN

RED

RED

WHITE

ELECTRICAL CONNECTIONS

4

Note: relay contact image in non-alarm condition, with the exception of the FAULT relay, which switches: contact 11-

12 open (NO) contacts 11-12 closed (NC) fault condition identification. Read the Alarms and Ventilation paragraph

on page 12 and see the opening of the fault contact.

RELAYS CONNECTION EXAMPLE

1

2

3

5

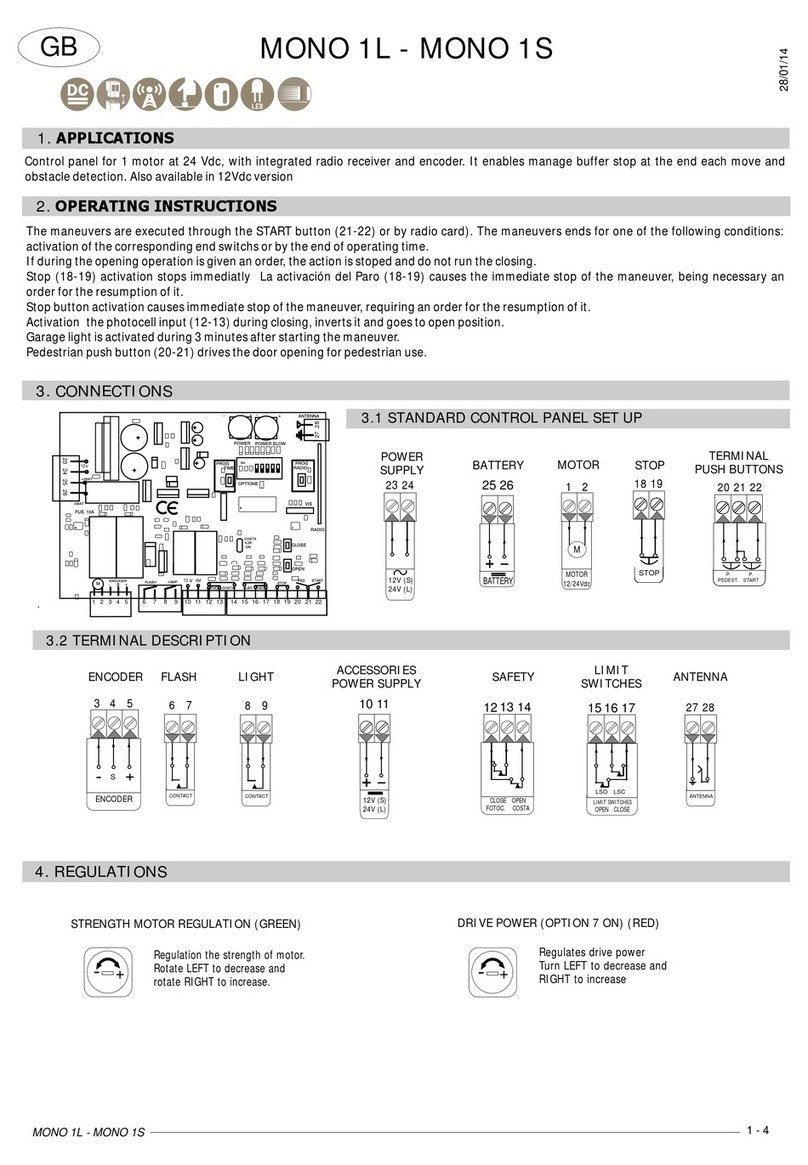

1)

Pt100 sensors (white-red-red)

4)

Access point key

2)

Power supply 85-260Vac-dc 50/60Hz.

5)

Antenna and Wi-Fi connector

3)

Relays (FAN2-FAN1-ALARM-TRIP-FAULT)

1MN0095 REV. 0

Output relay with 10A-250Vac-res COSФ=1 contacts.

COSФ=1.

STOP

SYSTEM

ALARM

CONDITION AUDIO AND

VISUAL INDICATION

Pt100 CONNECTION EXAMPLE

Note: before connecting the

sensors to the control unit, carefully

read the paragraph measurement

signal transfer on page 15.

1MN0157 REV. 0

The Wi-Fi antenna (5) is supplied with the NT935 WS device. If

necessary, the antennaconnection can be extended using a 5mm

SMA Male to Female antenna cable.

NOTE: Never start the device with the antenna disconnected.

12

NT935 WS

POWER SUPPLY

The NT935 WS control unit can be supplied by 85 to 260 Vac-Vdc, 50/60 Hz irrespectively of polarity in Vdc

(terminals 40-42).

This is obtained thanks to the use of a tested power supply unit, newly designed and manufactured, that frees installers from

worrying about the correct Vac and Vdc supply.

The ground must always be connected to terminal 41.

When the unit is supplied directly by the secondary of the transformer to protect, it can be burnt out by strong overvoltages.

This happens if the main switch is closed and the transformer has no load (blank test).

The above-mentioned problems are much more evident when the 220 Vac voltage is taken directly from the

transformer secondary bars and there is a fixed capacitor battery to phase the transformer itself.

.

If an existing control unit must be replaced with a new one, to guarantee its correct and safe operation, the

sensor/relay/supply connecting terminals must be replaced with the new terminals supplied.

ALARMS AND VENTILATION

Carry out the electrical connections on the removable terminal blocks only after disconnecting them from the unit.

When the control unit is in one of the modes mentioned below, it does not monitor the temperature and the relays are all

blocked. The fault contact switches and the fault LED flashes.

•Vis. programming display

•PRG Programming

•Relay test

The ALARM and TRIP relays switch only when the set temperature thresholds are exceeded.

The FAULT contact, programmed in failsafe mode (default YES), opens (11-12) when the equipment is supplied only if

the unit detects no fault on switching on, and stays in this condition until one of the following events occurs:

•Data memory fault (Ech message).

•Pt100 sensor fault (FCC short-circuited sensor, FOC interrupted sensor or Fcd quick temperature increase)

•CAL damage to the measurement circuit.

•Insufficient supply voltage.

•During the power on reset after programming (PRG), displaying the data (VIS) and test relay.

The FAULT failsafe can be disabled selecting FAULT failsafe "NO" see step 34-35 programming page 14.

NOTE: do not connect the FAULT relay to the transformer tripping circuit to avoid unwanted system interruptions.

FAULT AND RESET MESSAGE SEQUENCE

Find below the sequence of fault messages and RESET function condition.

1) ECH

2) CAL

3) FCD

4) ERR PT

The FAN1 and FAN2 contacts can be used to control the cooling fans, or they can be inserted in the conditioning system of the

transformer room, see paragraph cooling fan control on page 17.

NOTE: always disconnect the unit before performing any electrical connections.

11 12

FAULT 11-12 NC: ALARM FAULT OR POWER OFF

FAULT 11-12 NO: POWER ON OR NO FAULT

11 12

FAULT CONTACT (failsafe active)

eeprom fault

measurement circuit fault

quick temp. increase fault

FCC or FOC sensor fault

erasable message

erasable message

resettable condition

non-resettable condition

To protect the control unit against line overvoltages, the PT-73-220 electronic arrester, designed by TECSYSTEM S.r.l.

for this specific purpose, is recommended. Alternatively, it is advisable to use 110 V AC supply voltages or, even better,

110 VDC.

13

NT935 WS

PROGRAMMING

NT935 WS

STEP

PRESS

EFFECT

PRESS

NOTES

1

Keep the PRG key pressed until the display shows PRG

SET

2

Select PRG SET for entering in the programming mode

or PRG 1 to restore the default programmed value.

PRG 1 default value

3

The ALARM threshold for (CH 1-2-3) is displayed.

Set the desired threshold, the Alarm LED flashes

Default 90°C

4

The TRIP threshold for (CH 1-2-3) is displayed and the

Trip LED flashes.

5

Set the desired threshold

Default 119°C

6

FAN1 (CH 1-2-3) is displayed and the Fan1 LED flashes

Default YES

7

Select YES / NO / INT

If INT is selected

read function notes page

17 .

8

(CH4) is displayed

CH4 enabling

9

Select YES or NO

with YES CH4 is enabled

with NO CH4 is disabled

10

The ALARM threshold for (CH4) is displayed, the Alarm

LED flashes.

If CH4=NO jump to step

16, Default NO

11

Set the desired threshold

Default 120°C

12

The TRIP threshold for (CH4) is displayed.

The TRIP led flashes

13

Set the desired threshold

Default 140°C

14

FAN2 for (CH4) is displayed

Default Yes

15

Select YES or NO

16

ON (CH 1-2-3) is displayed and the FAN1 LED flashes

Default 70°C

17

Set the desired FAN1 ON threshold

If you select FAN1 NO, go

to step 21 if you select

INT the FAN1 and FAN2

LEDs flash.

18

OFF (CH 1-2-3) is displayed, the FAN1 LED flashes

Default 60°C

19

Set the desired FAN1 OFF threshold

14

NT935 WS

20

ON (CH4) is displayed, the FAN2 LED flashes

Default 45°C

21

Set the desired FAN2 ON threshold

If you select FAN2 NO, go to

step 24

22

OFF (CH 4) is displayed, the FAN2 LED flashes

Default 35°C

23

Set the desired FAN2 OFF threshold

24

HFN (NO) is displayed

The FAN1-FAN2 LEDs flash

Fan cyclic test

for 5 min. every “n” hours

25

Set the desired number of hours

Default NO = function

disabled

26

FCD (NO) is displayed

Fault for quick temperature

increase (°C/sec)

27

Set the desired value

(FCD info on page 19)

Default NO

(function excluded)

28

VOT (NO) is displayed

(VOTING info on page 16)

29

Select YES or NO

Default NO

(function excluded)

30

The display shows FLS (ALARM) flashing LED ALARM

(info FAIL SAFE on page 18)

31

Select YES or NO

Default NO

32

The display shows FLS (TRIP) LED flashes TRIP

33

Select YES or NO

Default NO

34

The display shows FLS (FAULT) LED flashes FAULT

35

Select YES or NO

Default YES

36

END is displayed

End of programming

37

Press ENT to save the set data

and exit programming

Err: incorrect programming of

the LED values (note 6)

38

Return to step 1

PROGRAMMING NOTES

1) The MODE key allows reversing the programming steps according to the sequence 28-26-8-1

2) The TEST key allows exiting programming without saving the modified data.

3) After 1 minute's keyboard inactivity programming is abandoned without saving the data.

4) During programming the control unit does not control/protect the monitored machine.

5) At the end of programming the control unit is restarted and the FAULT relay is disabled until the unit is fully

restarted.

6) If pressing ENT, “Err” appears, it means that one of the following mistakes has been made:

ERR ALL. = ALARM ≥ TRIP

ERR FAN = FAN-OFF ≥ FAN-ON. (FAN1 OR FAN2)

ERR INT = INT FAN-OFF ≥ FAN-ON (FAN1) DELTA <10°C

The device automatically switches to the programming step of the mistake.

NOTE: EVERY TIME THE CONTROL UNIT IS PROGRAMMED WITH DATA SAVING CONFIRMATION, THE VALUES

STORED IN T-MAX ARE RESET TO THE TIME OF SAVING.

15

NT935 WS

All "NT" series control units have linearity of the sensor signal, with a maximum error of 1% of full scale value.

NOTE: the use of cables not complying with the above could cause possible reading anomalies. It is always

important to take into account that any interference on the signal lines might cause anomalies on the Pt100

inputs (CH1-CH2-CH3-CH4.) or on the sensors themselves.

ATTENTION:

We recommend you check the device's programming before starting the device.

The default parameters set by TECSYSTEM might not match your requirements.

Programming the device is the end user's responsibility, the settings of the alarm thresholds and the enabling of

the functions described in this manual must be checked (by a specialised engineer) according to the application

and features of the system the control unit is installed on.

TEMPERATURE SENSORS

Each Pt100 thermometric sensor has one white and two red connectors (CEI 75.8 regulations).

The CH2 channel must be always referred to the central column of the transformer.

The CH4 channel must be always referred either to the core of the transformer or to the Pt100 ambient sensor if you wish to

thermo-regulate the transformer room using the NT935 WS control unit.

MEASUREMENT SIGNAL TRANSFER

All the cables transferring the Pt100 measurement signals must comply with the following under all circumstances:

1. Every Pt100 must be connected with a three-wire cable having a minimum section of 0.35mm² and a maximum of 1 mm².

2. The extension cable must be screened with tinned copper braid with an 80% cover

3. Conductors must be twisted, maximum recommended step 60mm

4. The cable screening must be grounded only with a termination, preferably on the unit side.

5. The sensors' signal transfer cable must not be near electrical cables, either low or medium-high voltage.

6. The Pt100 cable and the signal transfer cable must be laid in a straight line, without any winding.

7. Any caps used to butt conductors must be crimped properly to avoid false contacts.

NOTE: to install the sensors and signal transferring cable correctly, read the SCS/ SENSOR installation rules

manual.

What may happen when installation rules are not complied with.

1)The electrical field propagating from the power line of another circuit, couples capacitively with the conductors (in particular

with unscreened cables). The effect of this coupling creates a signal that overlaps the signal transmitted by the nearby

conductors, causing incorrect readings.

2) The variations in magnetic flux in the power lines may induce an electromotive force on the signal transferring cables (in

particular non-twisted cables), that, being a closed circuit, generates a current. This interference current, multiplied by the

circuit resistance, gives a voltage value that overlaps the signal to be transmitted, distorting the sensor measurement.

3) False contacts can alter the signal with the consequent variation in the temperature detected.

In specific cases, when the rules for connecting the Pt100 sensors are not complied with, the following anomalies can occur

between the SCS box and the temperature control unit:

a) incorrect temperature readings, alarms or anomalous tripping

b) mechanical / electrical fault of the Pt100 sensors

c) damage to the Pt100 inputs of the control unit.

TECSYSTEM S.r.l. has designed its own special cable to transfer the measurement signals, CEI-compliant, with all the

protection requirements provided for mod. CT-ES

16

NT935 WS

TEMPERATURE SENSOR DIAGNOSTICS

In case of failure or exceeded full scale value of one of the thermometric sensors installed on the machine to protect, the

FAULT relay opens immediately with the relative warning of faulty sensor on the corresponding channel (PT err).

Fcc indicates sensor short-circuited or minimum full scale value of the control unit exceeded -8°C (version 0°÷240°C)

and -48°C (version -40°C÷200°C)

Foc indicates sensor interrupted or maximum full scale value of the control unit exceeded 243°C (version 0°÷240°C)

and 203°C (version -40°C÷200°C)

To eliminate the message and reset the opening of the Fault contact, it is necessary to check the Pt100 connections and

replace the faulty sensor (if any). If the minimum/maximum full scale value has been reached, check that the ambient

conditions match the control unit reading.

Note: exceeding the minimum/maximum full scale value can also be caused by interference on the sensor lines; in this case

we recommend that you check:

the correct installation of the sensors and above all of the extension cable (as stated in the paragraph MEASUREMENT

SIGNAL TRANSFER)

the activation of: VOTING (see below) or FCD (see page 19) according to the conditions of the system.

CAL message display: it appears when damage is found in the measurement circuit. The temperature values displayed

might be incorrect. Return the control unit to TECSYSTEM for repairs.

VOTING FUNCTION

The voting function derives from the redundancy concept that consists in duplicating the components of a system to increase

their reliability.

How does VOTING work?

Using the redundancy principle, we use the sensors installed on the three phases U-V-W to monitor the transformer's

operation, and at the same time to ascertain the sensors are working correctly, discriminating against any false alarms

(generated by installation errors).

By activating the VOTING "YES" function, the control unit compares the temperature values recorded on the monitored

CH1-CH2-CH3 channels and enables the switching of the TRIP disconnect contact only if the TRIP threshold has been

exceeded on at least two channels over the same period T.

By selecting VOTING “NO” the function will be disabled.

Note: if Voting "Yes” is programmed, the switching of the ALARM contact will signal exceeding of the alarm threshold on

each individual channel.

To enable the Voting function, read the programming section on pages 13-14.

Attention: To control the transformer correctly from a temperature point of view, enabling the VOTING function

is allowed where the load distributed between the phases of the transformer is adequately balanced. In addition,

any conditions of FAULT: FCC-FCC-FCD on two or more channels, with active voting, can determine the TRIP

contact inhibition.

PROGRAMMED DATA DIAGNOSTICS

In case of failure of the internal memory or corruption of programmed data, just after switching on, Ech appears with the

relevant Fault contact signal.

In this case, for safety reasons, the default parameters are loaded automatically (see programming table on pages 13-14).

Eliminate the Ech indication by pressing RESET and run programming to enter the desired values.

Finally switch the unit off and back on to check the memory works correctly, if it is damaged Ech will be displayed again

(send the control unit to TECSYSTEM srl for repairs).

TEMPERATURE DIAGNOSTICS

When one of the temperature sensors senses a temperature 1°C higher thanthe alarmthreshold, 5 seconds later the ALARM

relay switches and the ALARM LED of the affected channel (CHn) lights up.

When the trip temperature limit is exceeded, 5 seconds later, the TRIP relay switches and the TRIP LED of the affected

channel (CHn) lights up.

As soon as the recorded temperature returns to values equal to or lower than the limit set for the ALARM and TRIP relays

switching, these relays de-energise and the corresponding LEDs switch off.

The ALARM and TRIP values are kept in the internal memory: they can be recalled by entering the Vis modes (programmed

parameter display) and modified in PRG (programming) mode.

17

NT935 WS

COOLING FAN CONTROL

The NT935 WS control unit is fitted with two FAN contacts (FAN1 and FAN2) and, if programmed correctly, can control the

fans switching ON and OFF to cool the transformer.

The FAN1 and FAN2 contacts can manage cooling of the transformer and the room where it is installed: the cabin.

By connecting FAN1 to the tangential ventilation system (the two bars on the transformer) and FAN2 to the extractor, you

will improve the air flow in the cabin; moreover, the cabin temperature will no longer need to be managed by a thermostat

outside the system.

The fans can be controlled in two different ways:

• Using the temperatures sensed by the sensors on the three columns (FAN1)

CHF 1.2.3

(e.g..ON at 70°C - OFF at 60°C)

• Through an additional sensor (CH4/YES) dedicated to the ambient temperature inside the transformer room (FAN2).

CHF 4

(e.g..ON at 45°C - OFF at 35°C)

The ON and OFF values are programmable according to the device range. The FAN ON must always be at least 1°C higher

than FAN OFF (recommended ΔT FAN ON_OFF +10°C).

The FAN 1/ 2 LED lights up when the temperature exceeds 1°C the FAN ON threshold, the corresponding relay switches,

and turns off when the temperature goes below 1°C the FAN OFF threshold, the corresponding relay switches.

FAN TEST

By programming (HFn), it is possible to have the fans operating 5 minutes every "xxx" hours, regardless of the column or

ambient temperature values (i.e.: with HFn=001 the fans are activated for 5 minutes every hour).

This function aims at verifying the fan operation and their control apparatus periodically.

By setting NO this function is inhibited.

To enable the HFN function, read the programming section on pages 13-14.

INTELLIFAN FUNCTION

What it is used for:

The Intellifan function allows reducing the transformer's thermal shock by partially anticipating (one bar at the time) the

activation of the tangential ventilation system.

The reduction in the transformer's thermal shock will extend the life of the transformer and of the ventilation system itself.

By enabling the FAN1 "INT" function, the control unit will alternate the activation (each 30 minutes) of the FAN1 and FAN2

contacts, anticipating the activation of the ventilation system at the intermediate value included between FAN1 ON and FAN1

OFF.

EX. FAN1 ON = 70°C and FAN1 OFF = 60°C FAN INT. ACTIVATION = 65°C

Before enabling the function, check that the connection of the two ventilation bars is distributed in such a way that the RH

bar is connected to the FAN2 relay, pins 1-2, and the LH bar is connected to FAN1, pins 3-4.

By selecting FAN1 "NO or YES", the function will be disabled.

Note: once the FAN1 threshold is exceeded, the control unit will activate both bars.

To enable the INTELLIFAN function, read the programming section on pages 13-14.

Note: for correctly working of the INTELLIFAN function we recommend you observe ΔT 10°C between FAN1 ON and

FAN1 OFF. The connection to the VRT series devices, where Intellifan is enabled, must be made between the

contacts FAN1 - COM-EN1 and FAN2 - COM-EN2.

IMPORTANT WARNING

Before carrying out the isolation test of the electrical panel the control unit is installed on, disconnect it together

with the sensors from the power supply to prevent it from being seriously damaged.

18

NT935 WS

TECHNICAL SPECIFICATIONS OF THE EXTENSION CABLE FOR Pt100

1. Cable 20 x AWG 20/19 Cu/Sn

2. Section 0.55 mm²

3. Flame-protection insulation PVC105

4. Standards CEI 20.35 IEC 332.1

5. Maximum operating temperature: 90°C

6. Configuration: 4 triples of three twisted and coloured conductors

7. Screen on Cu/Sn

8. Fireproof PVC sheath

9. Outer diameter 12 mm

10. Standard configuration in 100 m coils

The NT935 WS has n.o selection (contact open)/ n.c (normally closed contact) for ALARM, TRIP and FAULT relays,

programming steps 30 to 35 page 14. The selection of the setting YES/NO introduces functions Fail Safe and No Fail Safe.

ALARM AND TRIP

Setting NO (NO Fail safe) normally open contacts are in positions 5-7 Alarm and 8-10 Trip, they switch only when limits are

reached preset temperature.

Setting YES (Fail Safe) normally closed contacts are in positions 5-7 Alarm and 8-10 Trip, they switch only when limits are

reached preset temperature or for device's power supply lack.

FAULT

Setting YES (Fail safe) the contact 11-12 is positioned as normally open, switches (closed) when a fault condition is

identified; see section on page 12 alarms and ventilation.

Setting NO (NO Fail safe) the contact 11-12 is positioned as normally closed, switches (open) when a fault condition is

identified; see section on page 12 alarms and ventilation.

Disabling the failsafe function on the fault contact, the unit will no longer be able to report the fault for lack of power. In this

case it is suggested that the enabling of the fail safe on the ALARM contact for the above indication.

NOTE: When the unit is located in one of the methods described below does not monitor heat, also the relay will all be

banned, the FAULT led start blinking.

•Vis. display programming.

•PRG programming.

•Test of the relays.

The FAIL SAFE is temporarily disabled The FAULT relay switches.

ATTENTION: accessing at the relay test mode will temporarily disable the failsafe function, the relays with function

enabled switch (ALARM-TRIP-FAULT).

FAIL SAFE FUNCTION

19

NT935 WS

The NT series equipment boasts an innovative control function combined with the dynamic status of the Pt100 sensor.

Activating FCD, the control unit analyses the increase in temperature ∆T (*) recorded in a second (°C/sec).

Enabling the function, the user can select the value (∆T) from a minimum of 1°C/sec to a maximum of 30°C/ sec. If the

value sensed is higher than the value set by the user, the control unit inhibits the possible activation of the ALARM and

TRIP alarms and switches the FAULT relay (11-12), displaying the message "Fcd fault".

Example: if we set the function to 5°C, FAULT will switch for FCD only if the control unit senses an increase in ∆T of over

5°C in a second on the monitored system.

Setting "no" disables the FCD function.

When a channel is in FAULT for FCD, the relative Alarm and Trip warnings are inhibited on the single channel; therefore ly

the over-quick temperature increase is highlighted.

Press Reset to delete the FCD warnings on all channels and reset the FAULT relay.

Possible FCD applications

Identification of a possible induced interference on the Pt100 sensor line

If the installation instructions are not complied with (see page 15), any interference on the Pt100 sensor line can cause

false readings or anomalous alarms.

Setting the FCD function in a temperature range of between 1°C and 10°C (5°C recommended), the effects caused by false

readings can be suppressed and the alarm relay activation can be prevented, as shown above.

Corrective actions: check the installation of the sensor extension cable is in line with the instructions given in the paragraph

on the measurement signal transfer on page 15.

Identification of a sensor fault or faulty connection

In case of a faulty connection or sensor fault, a quick positive or negative variation in temperature might occur, leading to

the system tripping or the alarms of the monitored system to be triggered.

In this specific case we recommend the FCD function to be set in a temperature range of between 10°C and 20°C.

Corrective actions: check the terminals the sensor is connected to are tightened and replace the faulty sensor, if required.

Identification of the electrical motor rotor block

In case of temperature control of the electrical motors, the quick temperature increase might be due to a blocked rotor.

In this specific case we recommend the FCD function to be set in a temperature range of between 20°C and 30°C.This

setting is recommended in order to prevent the FCD function from activating during motor start-up, or where the ΔT/sec.

increase varies quickly.

(*) The ΔT value shows the temperature range for each second.

NOTE: you should not enable the FCD function with active VOTING.

FCD FUNCTION

NT935 WS WI-FI CONNECTION

The NT935 WS control unit has a built-in WEB SERVER that is accessible via Wi-Fi connection.

What is needed to access the NT935 WS control unit?

To access the web server a device with a Wi-Fi connection and an Internet browser is needed.

How to connect on the first start? “Access Point” mode

Power the control unit by keeping the button on the back pressed

for approximately 5 seconds.

NOTE: Access point key

The access point key allows the user to temporarily access the web server in the

"Access Point" mode, forcing operation with the IP address 192.168.8.8.

How it works:

With the control unit off, keep the access point button pressed, then power the

device and release the button after approximately 5 seconds

20

NT935 WS

Launch the search for Wi-Fi networks from your device (PC, Smartphone or Tablet).

NOTE: the name of the network to connect to consists of: TECSYSTEM followed by the serial number S/N of the device and

the year of production (18 = 2018), values shown on the identification label of the product purchased.

Select the TECSYSTEM (S/N + YEAR) network.

Click on CONNECT

The TECSYSTEM network requires the insertion of a digital network key: TECSYSTEM in the network key window, repeat

the operation in the network key confirmation window.

Click on CONNECT

Once the connection is established, your device will indicate Connected TECSYSTEM.

NOTE: Connecting to the NT935 WS network will result in automatic disconnection from other networks; for devices such as

Smartphones or Tablets it may be necessary to disable the data connection.

Having connected to the TECSYSTEM network (S/N + YEAR) open your browser program and type in the address

192.168.8.8, that follows on page 21.

TECSYSTEM (S/N + YEAR)

TECSYSTEM (S/N + YEAR)

TECSYSTEM…

TECSYSTEM (S/N + YEAR)

TECSYSTEM

Other manuals for NT935 WS

1

Table of contents

Other TECSYSTEM Control System manuals

TECSYSTEM

TECSYSTEM NT538 User manual

TECSYSTEM

TECSYSTEM VRT300 Series User manual

TECSYSTEM

TECSYSTEM VRT600 SERIES User manual

TECSYSTEM

TECSYSTEM T119 DIN User manual

TECSYSTEM

TECSYSTEM TRBH User manual

TECSYSTEM

TECSYSTEM VRT600 SERIES User manual

TECSYSTEM

TECSYSTEM FO 935 User manual

TECSYSTEM

TECSYSTEM FO 935 ETH User manual

TECSYSTEM

TECSYSTEM T119 Manual

TECSYSTEM

TECSYSTEM T30 User manual