4

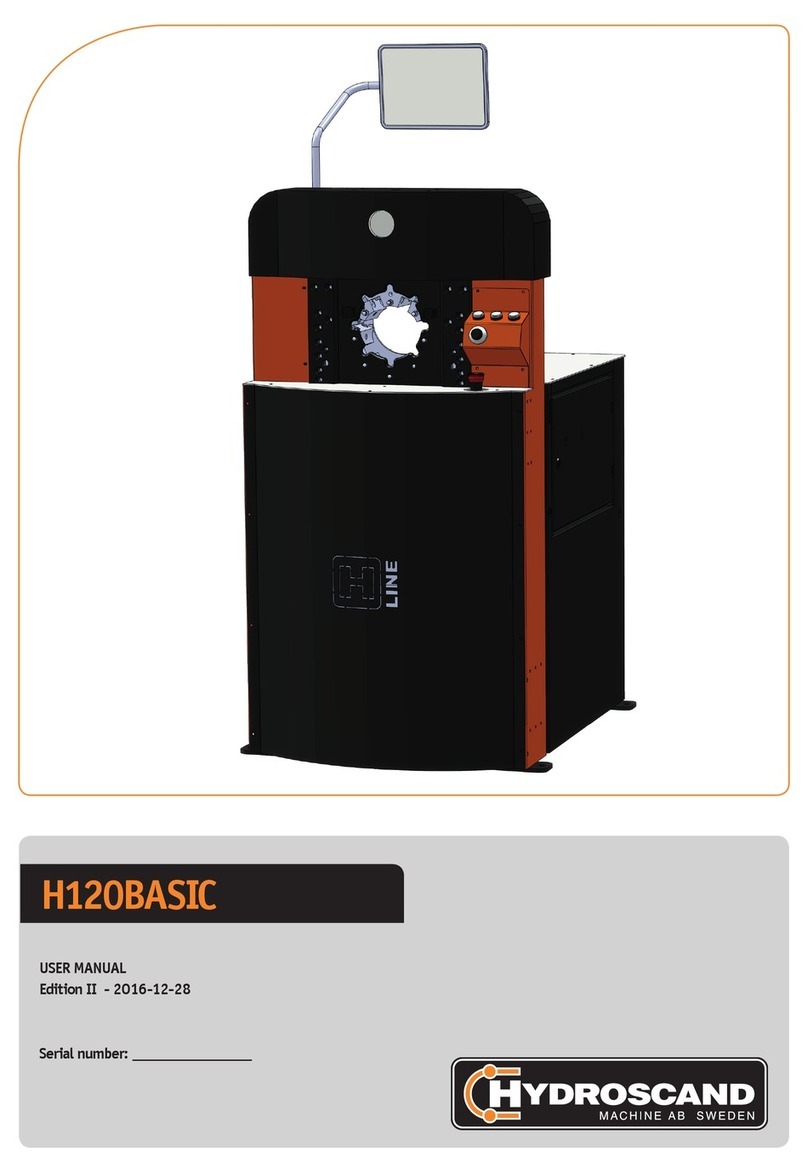

1. Introduction

Do not unpack or operate the crimping machine until you have thoroughly

read this manual.

-

-

information if necessary.

-

with other machine documentation.

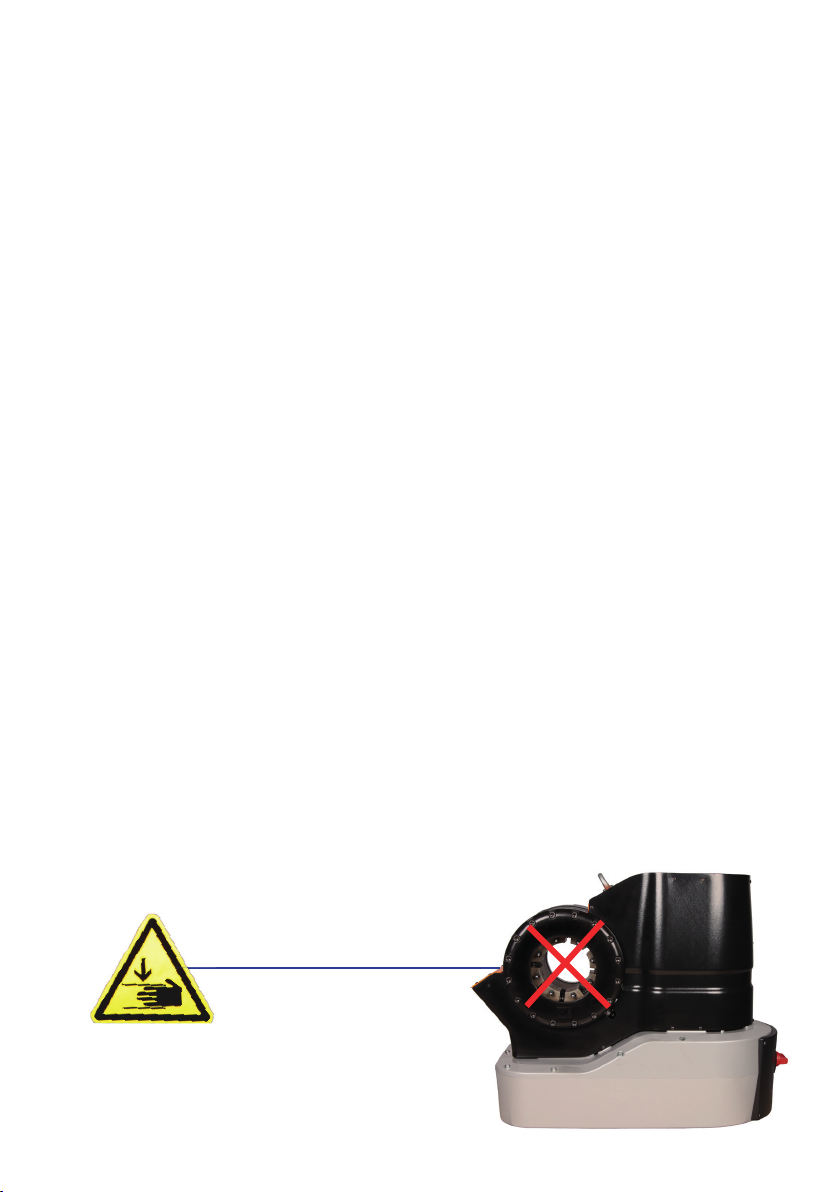

2. Safety rules

-

-

-