- 7 -

Time zones

The switch-on and –off times of the unit can be programmed in the menu ‘Time zones’after the

operation mode ‘Timer control’was retrieved. One such setting is possible per day.

A group of several days or also individual days can be programmed by the operator. Switch-on

and switch-off times are controlled and initiated by the internal timer.

Groups: Mo ... Su

(several days)

Mo ... Fr

Sa ... Su

Individual days: Mo, Tue, Wed, Thu, Fr, Sa, Su

and so on –for every day in the week.

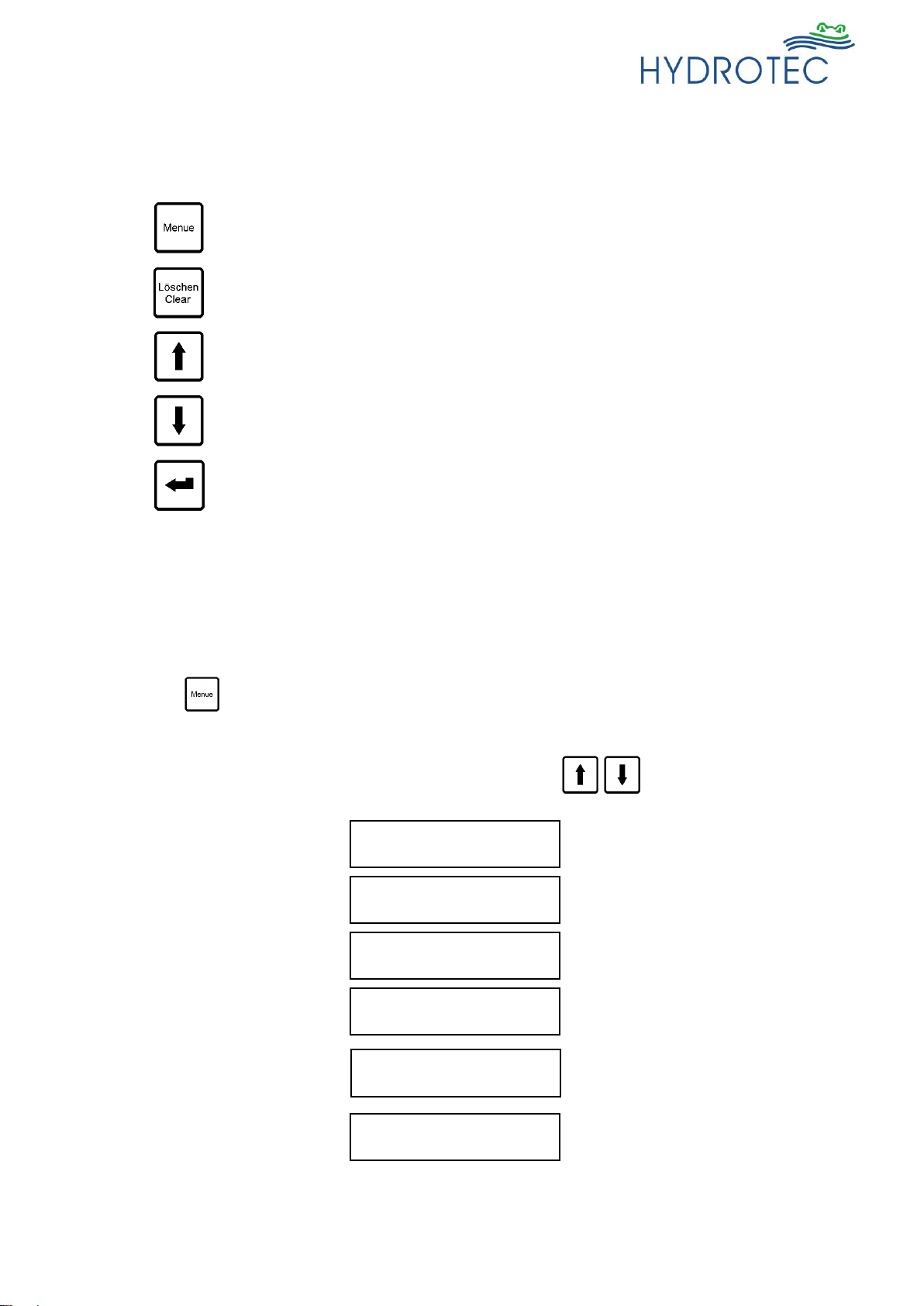

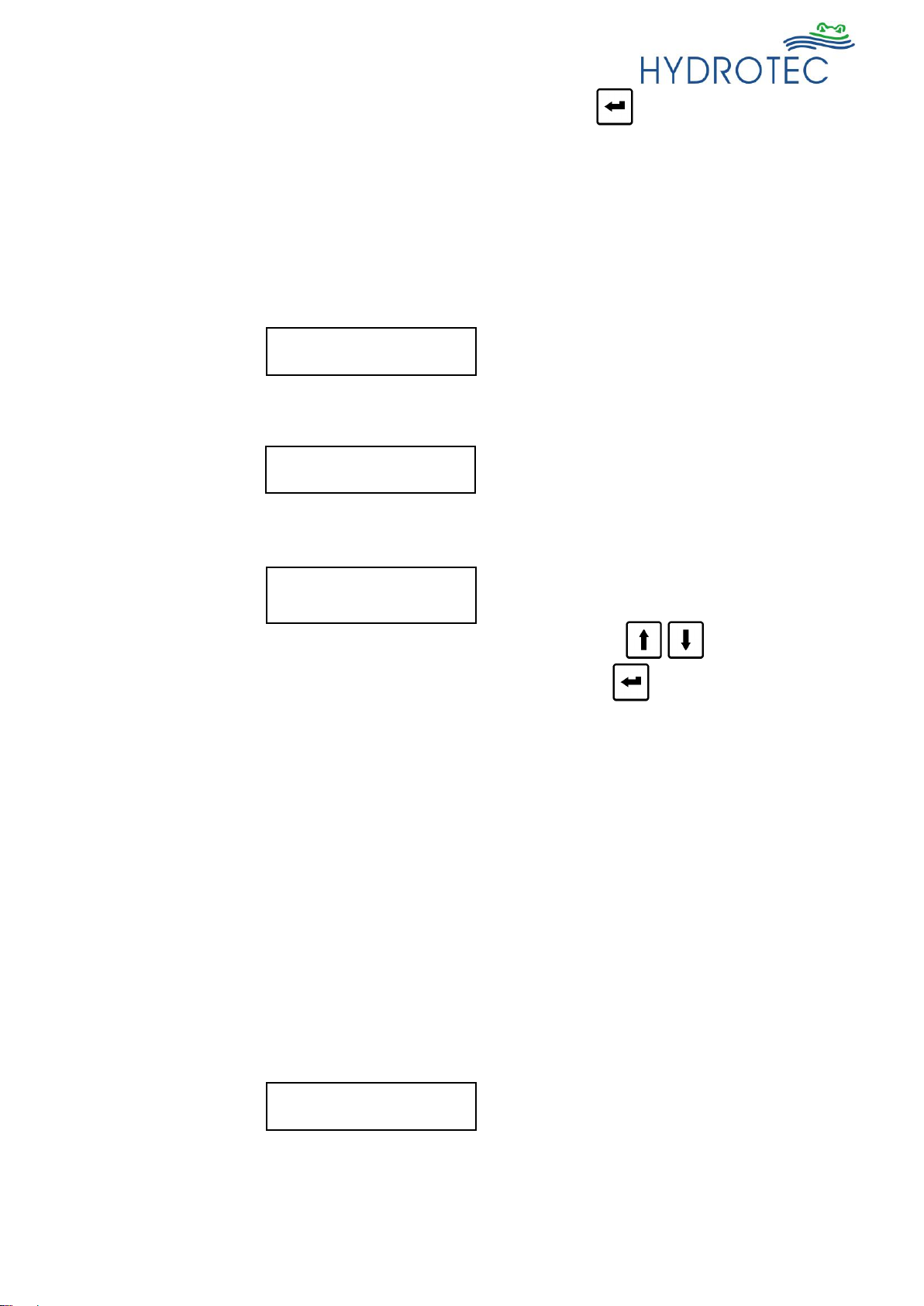

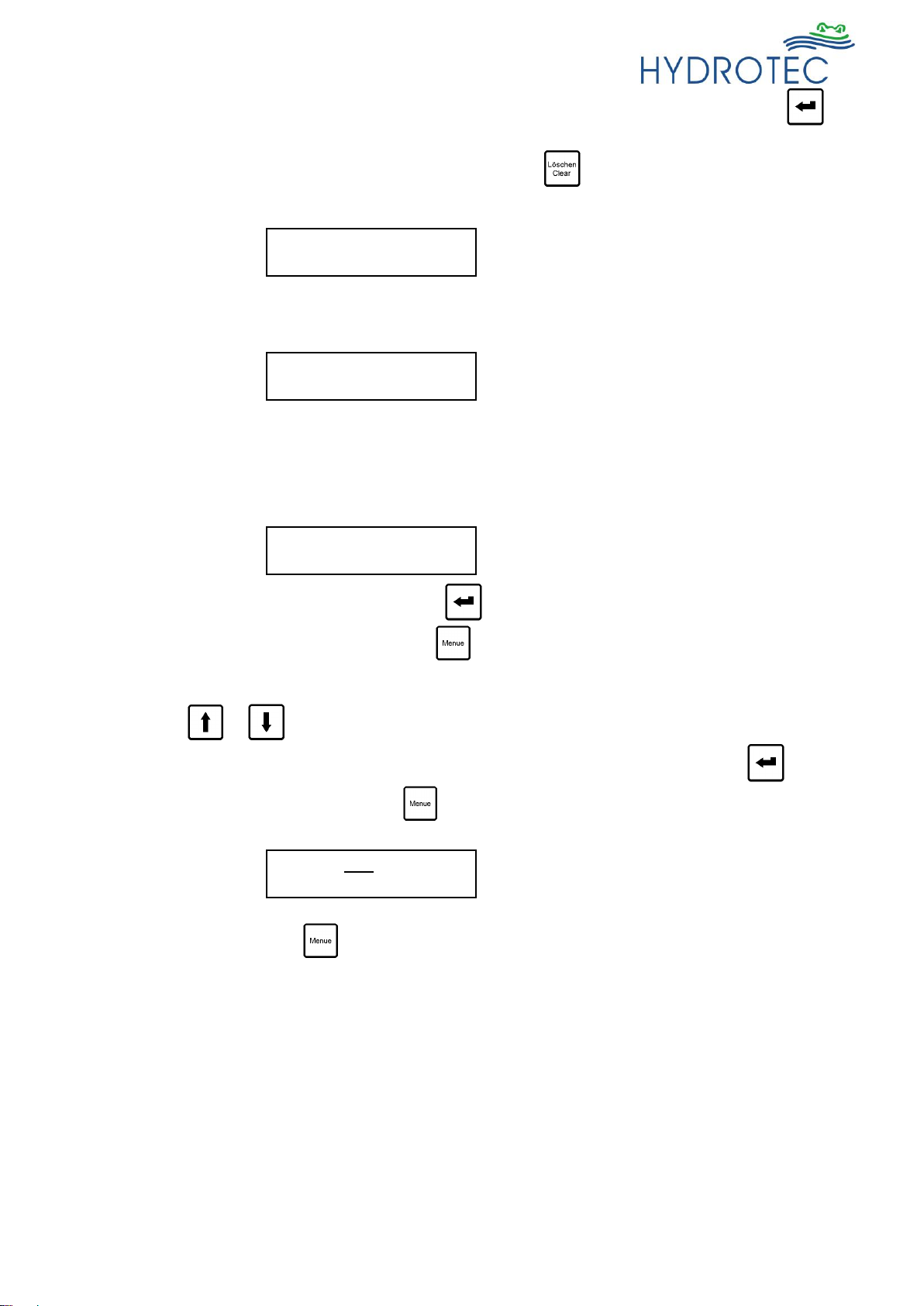

An initial selection of the desired menu is possible with the Cursor buttons , the menu

is then retrieved by pressing the button once and the switching times can then be altered

with the Cursor buttons. The figure that can actually be altered is marked with a line underneath.

Once the correct setting is achieved, the button must be pressed until the line underneath

is no longer visible. If the total switch settings for the selected and retrieved group of days /indi-

vidual day are to be cleared, press the button once.

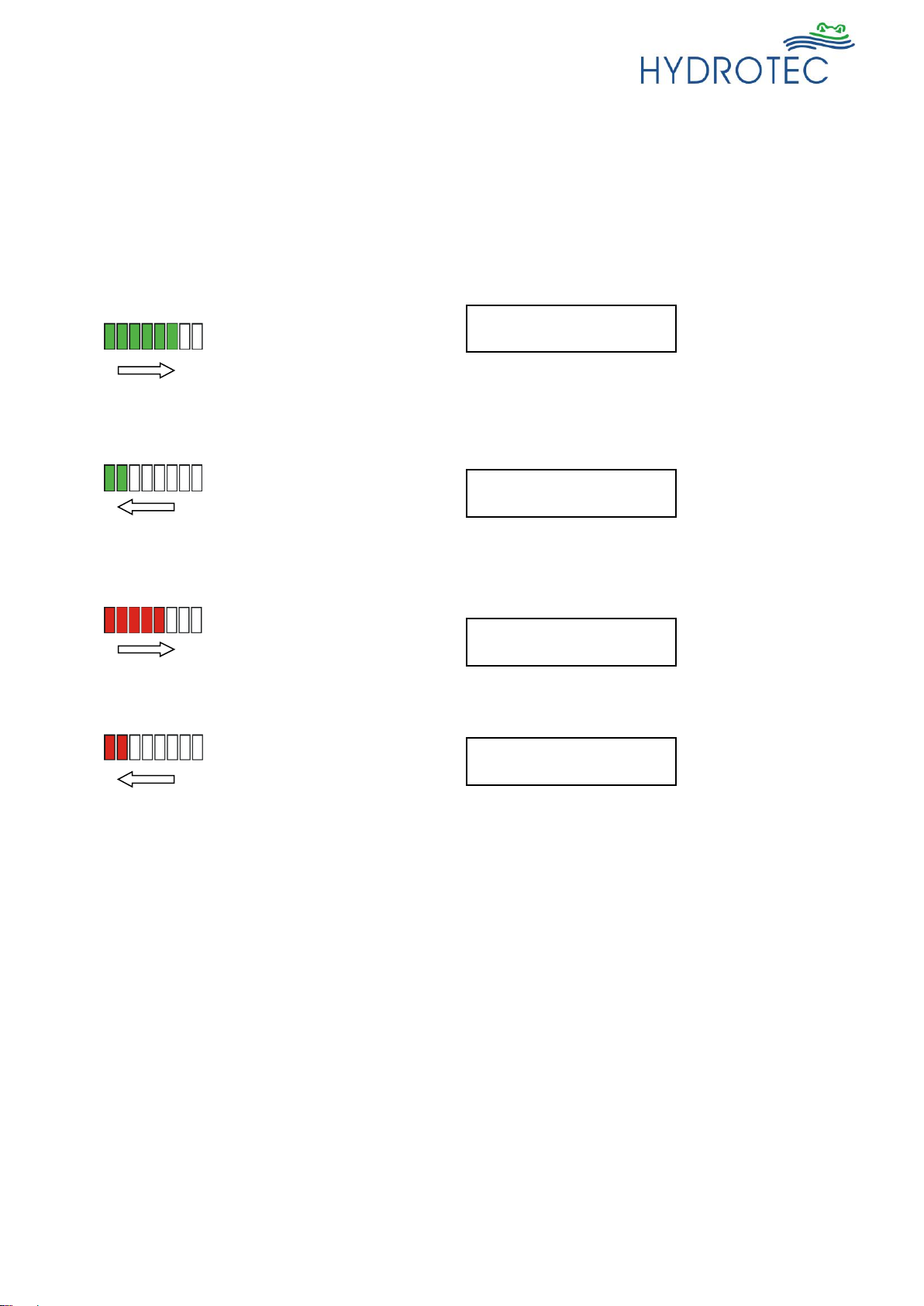

The times for switch-on and switch-off can be selected right on the dot. Below is an example for

setting switch time - group of days Mo-Su, switch-on 6.00 a.m., switch-off 10.00 p.m.

NOTE: If times different to the individual days than provided in the corresponding group of

days are set, the displayfor the group of days show**:**-**:** and the actual switch

time is set in the day monitoring.

If the switch-off time is set earlier than the switch-on time or if the times were reset

(00:00-00:00), the water conditioning unit is not activated that day(s).