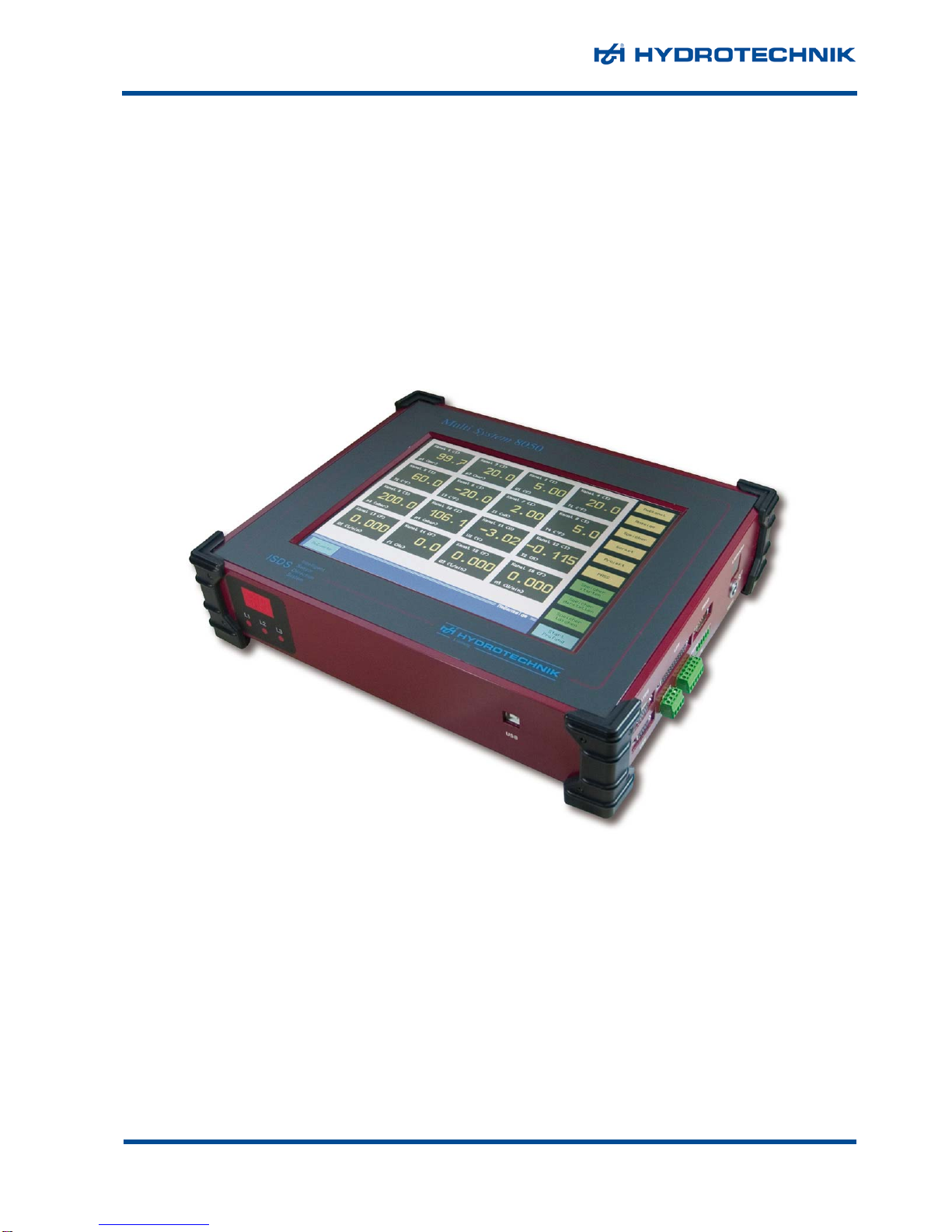

MultiSystem 8050

Operating Instructions Manual

© Hydrotechnik GmbH All rights reserved Page 3 of 62

Rev. 2.5 EN • Firmware version 3.3

8.6 HYDROlink operation menus.......................................................................................... 59

8.6.1 Program menu................................................................................................................59

8.6.2 Menus menu...................................................................................................................59

8.6.3 View menu......................................................................................................................59

8.6.4 Instruments menu...........................................................................................................59

8.6.5 Configuration menu ........................................................................................................59

8.6.6 HYDROrun menu............................................................................................................60

9Technical Data ..............................................................................................................61

Illustrations

Pic. 1 Front view.........................................................................................................................8

Pic. 2 Rear view..........................................................................................................................9

Pic. 3 Right-side connectors.......................................................................................................9

Pic. 4 Rear side connectors........................................................................................................9

Pic. 5 Start screen ....................................................................................................................13

Pic. 6 Measuring display...........................................................................................................14

Pic. 7 Elements on the screen..................................................................................................14

Pic. 8 Display mode „TEXT“......................................................................................................15

Pic. 9 Display mode „GRAPHIC“ ..............................................................................................16

Pic. 10 Virtual keyboard..............................................................................................................17

Pic. 11 Virtual 10-key pad...........................................................................................................18

Pic. 12 Channel menu ................................................................................................................18

Pic. 13 Configure analog inputs..................................................................................................19

Pic. 14 Zero point alignment.......................................................................................................20

Pic. 15 Linearisation function......................................................................................................20

Pic. 16 Enter linearisation table ..................................................................................................21

Pic. 17 Configure inputs for voltage/current................................................................................21

Pic. 18 Configure frequency inputs.............................................................................................22

Pic. 19 Configure trigger input ....................................................................................................23

Pic. 20 Configure trigger output..................................................................................................24

Pic. 21 Configure digital inputs ...................................................................................................25

Pic. 22 Configure digital outputs.................................................................................................25

Pic. 23 Configure analog outputs................................................................................................26

Pic. 24 Configure calculated channels........................................................................................27

Pic. 25 Configure CAN channel..................................................................................................28

Pic. 26 Display menu..................................................................................................................29

Pic. 27 Adapt scaling..................................................................................................................30

Pic. 28 Assign colors and symbols .............................................................................................31

Pic. 29 Set contrast.....................................................................................................................32

Pic. 30 Memory menu.................................................................................................................32

Pic. 31 Define trigger..................................................................................................................33

Pic. 32 Device menu...................................................................................................................34

Pic. 33 Set channel filters ...........................................................................................................35

Pic. 34 Hardware setup ..............................................................................................................36

Pic. 35 Compact Flash information.............................................................................................37

Pic. 36 Project menu...................................................................................................................38

Pic. 37 HYDROrun menu............................................................................................................39

Pic. 38 Release HYDROrun .......................................................................................................40

Pic. 39 Delete test procedures....................................................................................................41

Pic. 40 Initiate recording.............................................................................................................42

Pic. 41 Present series of measurement......................................................................................43

Pic. 42 Select measurement data...............................................................................................44

Pic. 43 Adapt presentation parameters.......................................................................................45

Pic. 44 Adapt scaling..................................................................................................................46

Pic. 45 Adapt graphic settings ....................................................................................................47

Pic. 46 Graph y = f(t) ..................................................................................................................48

Pic. 47 Use spot values..............................................................................................................49

Pic. 48 Use delta spot values .....................................................................................................50

Pic. 49 Graph y = f(x)..................................................................................................................51

Pic. 50 Table...............................................................................................................................51

Pic. 51 Select intermediate values..............................................................................................52

Pic. 52 Intermediate values ........................................................................................................52

Pic. 53 Display statistical data ....................................................................................................53

Pic. 54 Starting a test procedure.................................................................................................54