Introduction

The Hydroguard is a state of the art hydrodynamic separator. Hydrodynamic separators

remove solids, debris and lighter than water (oil, trash, floating debris) pollutants from

stormwater. Hydrodynamic separators and other water quality measures are mandated

by regulatory agencies (Town/City, State, Federal Government) to protect storm water

quality from pollution generated by urban development (traffic, people) as part of new

development permitting requirements.

As storm water treatment structures fill up with pollutants they become less and less

effective in removing new pollution. Therefore it is important that storm water treatment

structures be maintained on a regular basis to ensure that they are operating at optimum

performance. The Hydroguard is no different in this regard and this manual has been

assembled to provide the owner/operator with the necessary information to inspect and

coordinate maintenance of their Hydroguard.

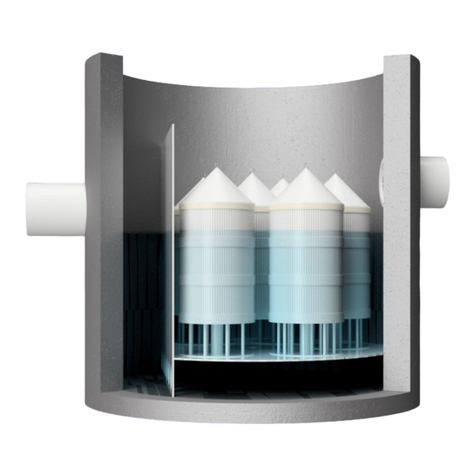

Hydroworks®HG Operation

The Hydroworks HG separator is unique since it treats both high and low flows in one

device, but maintains separate flow paths for low and high flows. Accordingly, high flows

do not scour out the fines that are settled in the low flow path since they are treated in a

separate area of the device as shown in Figure 1.

The HG separator consists of three chambers:

1. an inner chamber that treats low or normal flows

2. a middle chamber that treats high flows

3. an outlet chamber where water is discharged to the downstream storm system

Under normal or low flows, water enters the middle chamber and is conveyed into the

inner chamber by momentum. Since the inner chamber is offset to one side of the

structure the water strikes the wall of the inner chamber at a tangent creating a vortex

within the inner chamber. The vortex motion forces solids and floatables to the middle of

the inner chamber. The water spirals down the inner chamber to the outlet of the inner

chamber which is located below the inlet of the inner chamber and adjacent to the wall of

the structure but above the floor of the structure. Floatables are trapped since the outlet

of the inner chamber is submerged. The design maximizes the retention of settled solids

since solids are forced to the center of the inner chamber by the vortex motion of water

while the outlet of the inner chamber draws water from the wall of the inner chamber.

The water leaving the inner chamber continues into the middle chamber, again at a

tangent to the wall of the structure. The water is then conveyed through an outlet baffle

wall (high and low baffle). This enhances the collection of any floatables or solids not

removed by the inner chamber. Water flowing through the baffles then enters the outlet

chamber and is discharged into the downstream storm drain.