Congratulations! You now own a state of the art 1/10

scale oval race car. The Hyperdrive Pro 3 Solid Chassis

has gone through months of testing by our factory

drivers to insure that you get a car that has maximum

performance and adjustability built in. In purchasing this

kit you have not only helped the hobby and sport of Oval

pan car racing by supporting your local hobby shop but

you have also bought the quality of a Hyperdrive Racing

performance product.

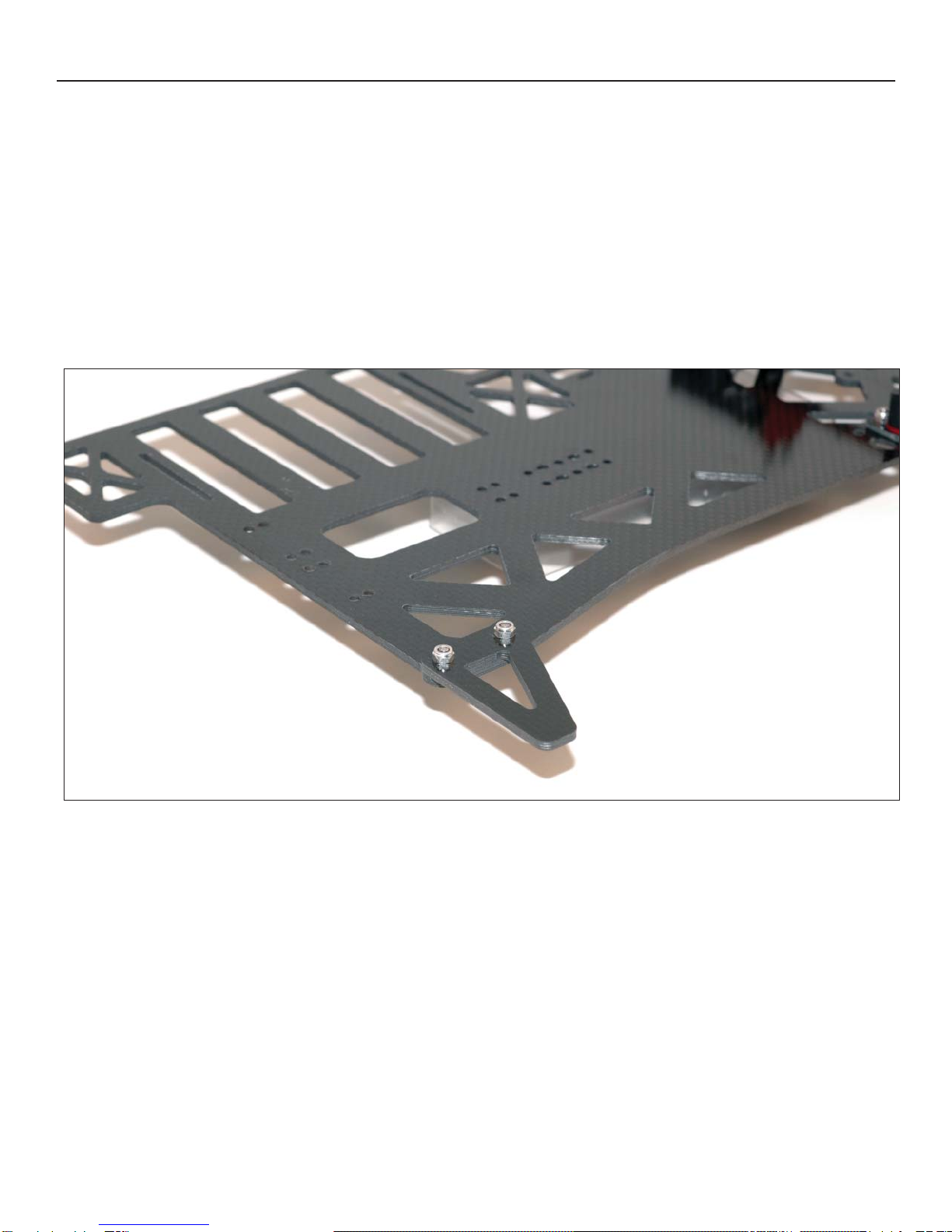

How well your car performs is dependant upon the

assembly of your car kit. Take your time and assemble

your car as shown in this manual. This will give you a

good starting point from which you can make adjustments

dependant upon the track you are racing on.

The following items are required to complete your car:

• Two channel Surface Radio

• Electronic Speed Control

• Batteries (4 cell)

• 05 Electric Motor

• Shock Oil

• Tires

• Body

Tools needed in the construction of your car:

• Phillips Screwdriver

• Hobby Knife

• Allen Wrenches; 3/32, 1/16 & 0.050

• Pliers or appropriate sized Nut Drivers/Sockets

Introduction