Steambrite Supply

Steambrite Supply Created on: : Monday 20 September, 2021

>

any excess grease from pump cavity.

-5-

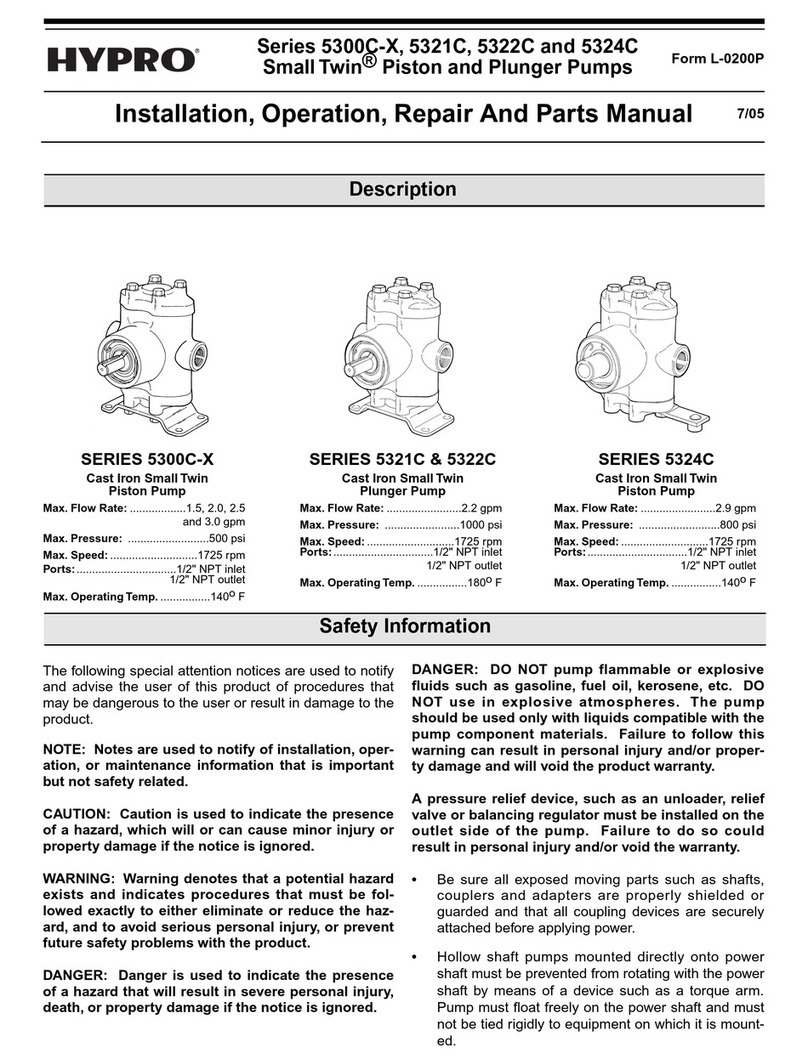

Used for Series

Ref. Part No. Description 5321 5324 5300

A 1055-0005 Seal Ring Seating Tool •

B 3010-0052 Valve Cage Extractor • • •

C 3010-0061 Main Bearing Support Tool • • •

D 3010-0063 Cam Bearing Support Tool • • •

E 3010-0064 Support Bars (Qnty 2) • • •

F 3010-0065 Pry Bar • • •

G 3010-0066 Wire Brush • • •

H 3010-0067 Wire Brush Holder • • •

I 3010-0071 Valve Seat Extractor • • •

J 3010-0222 Seal Ring Seating Tool •

K 3020-0001 3/16" Allen Wrench • • •

L 3020-0003 1/8" Allen Wrench • • •

M 3020-0009 1/16" Allen Wrench • • •

Repair Instructions

Recommended Repair Tools

For Hypro Small Twin Piston/Plunger Pumps

Figure 6 Recommended Repair Tools

Recommended Shop Tools

Bench Press, Arbor Press, Air Gun or Electric Hand

Drill, Metal Pipe, Support Fixture, (3" diameter x 4 1/2"

high), Ratchet Handle Wrench with 9/16" Hex Socket,

Bolt (3/8" diameter x 4 1/2" long), No. 320 Grit Emory

Cloth, Pliers, Small Knife, Large File, Claw Hammer,

Standard Screwdriver, Lubricating Spray (WD-40 or

LPS), Wire Brush (hand or machine), Stationary Belt

Sander, and Cleaning Solvent Tank (recommended)

Inspection of Pump Parts

When disassembling pump, thoroughly inspect all

parts and replace if necessary, with special consideration

given to the following areas:

1. Inspect Pump Body for erosion at O-ring seal

points in Valve and Piston bores. Check for wear

resulting from Main Bearings turning in Housing,

especially the Front Bearing area closest to the

Cam Bearing. Check for cracks in the Pump Body,

particularly at the discharge port and along the

casting seam (See Figure 7).

2. Inspect for excessive wear on the Cylinder Heads.

This can result from erosion and/or valve seat

hammer (See Figure 7).

3. Inspect for pitting and general wear in the Unitized

Valves, particularly where the Poppets seal

against the seat. If this area is worn, replace all

four Valves (See Figure 7).

4. Inspect the Connecting Rod. If there is more than

.007" wear in the total space between the