-5-

chamber should be flushed and drained to avoid chemical

corrosion and damage from freezing. Drain by removing the

lower drain plug.

Controlling the Pump Flow

Thebestwaytocontroltheflowisbyincorporatingtwocontrol

valves in a pipe tee immediately after the strainer in the

discharge line. This permits controlling agitation flow

independently of nozzle flow.

In any centrifugal pump, it is the large volume of liquid which

putsloadonthedrive.Useonlytheflowneededtodevelopthe

pressure required at the boom and to maintain adequate

agitation.Hydraulicmotor-driven centrifugalpumpsareeasily

adjusted to the exact flow required, as explained in the

Operating Instructions of this manual.

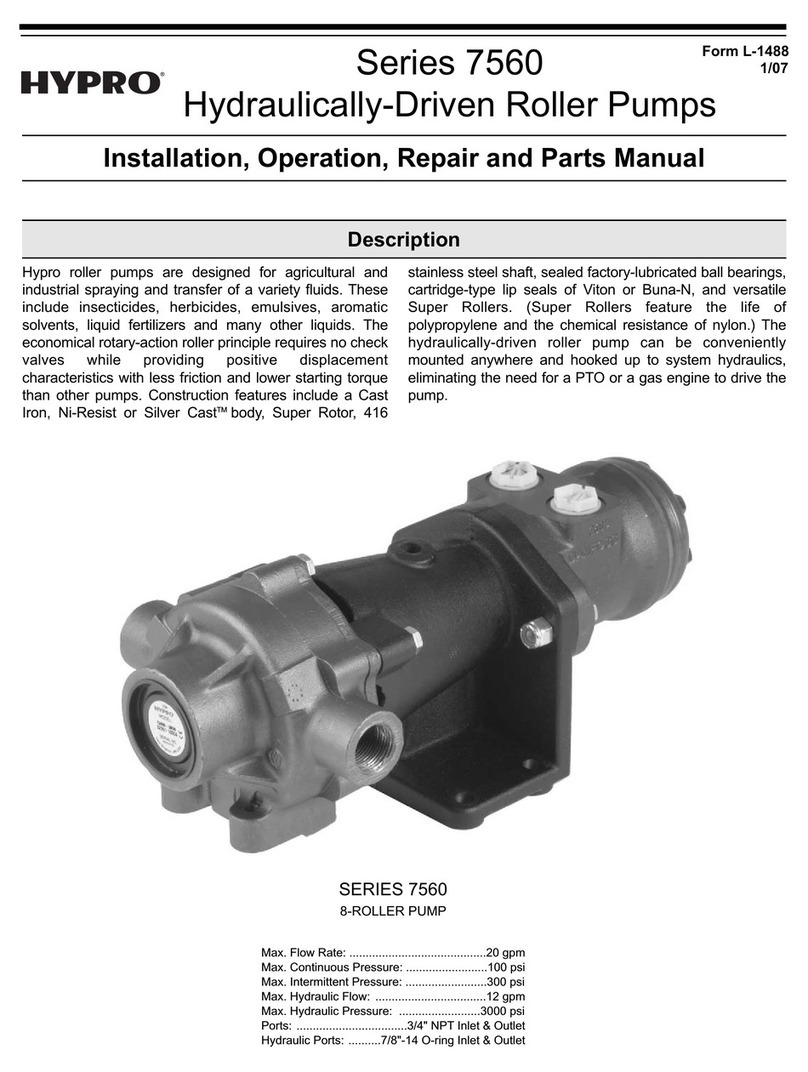

Hooking Up the Hydraulic Motor to the

Tractor Hydraulic System

HyproSeries9300HMChydraulicmotor-drivenpumpscanbe

mounted on either the tractor or sprayer. When hooking up,

make sure that no dirt or liquid gets into the hydraulic motor.

Keep all hydraulic connections clean. Be sure to connect

the hydraulic motor into the system correctly by putting the

pressurelinetothePressurePortAdapterandreturnlinetothe

Tank Port Adapter. The port adapters on the hydraulic motor

are sized to accommodate 1/2" NPT fittings. For maximum

performance, the hydraulic lines should also be at least 1/2"

[12.7mm]insize.Forlineslongerthan8feet[2.44m]orforthe

HM3Cmodels,hydrauliclinesizeshouldbeatleast3/4"[19.05

mm] in order to reduce heat generation.

Thetank(OUT)portadapterwithabuilt-incheckvalveassembly

willguardagainstreverseoperation —allowing youtoreverse

oilflowtooperateotherequipment.Thisadaptermustnotbe

removed. On HM2C and HM4C model pumps, the pressure

(IN)portadapterisatwo-pieceassemblyconsistingofanopen

(unrestricted)adapterwiththreeorificespackedloose with the

pump (See the Operations Section).

WhenusingtheHM2CorHM4Cunitonanyflowcompensated

(loadsensing)closed center system, or anysmall open center

systemwithamaximumflowof8gpm[30.28lpm]forHM2Cor

10 gpm [37.85 lpm] for HM4C, the metering orifice should be

removed from the pressure port adapter. When using these

units on flow compensated systems, connect to the motor

priority circuit if your tractor has one.

Standardspoolvalves,whicharefoundon all tractor hydraulic

systems,cancausepotentiallydamaginghighpeakpressures

in the hydraulic system when closed, because of abrupt shut-

offofoilflowinboththesupplyandreturnlines. Whenshutting

offthepump,movetheselectortotheFLOATpositiontoallow

the centrifugal pump to come to a stop gradually.

Operation

Open Center Systems—All Models

Adjusting Centrifugal Pump Output

HM1C and HM3C motors have a bypass screw set 1-1/2

turns from fully closed at the factory. HM2C and HM4C

have the bypass screw fully closed from the factory.

1. Open the bypass adjustment screw 2-1/2 turns from fully

closed. Turn the bypass screw in to achieve the flow for

the desired gpm and psi.

2. Startthetractor. Leavethedirectionalvalveintheneutral

position and allow hydraulic oil to circulate for approxi-

mately 10 to 15 minutes or until adequately warmed.

4. Primethecentrifugal pumpwithall valves open (See the

Installation Instructions and System Configuration Dia-

gram).

5. Close the agitation line valve and keep the control valve

and the boom shut-off valve open. Note the spray

pressure.

7. Open the agitation line valve until you have desired

circulation in the tank. Recheck the spray pressure. If it

is too low, close down the agitation line valve until the

desired spray pressure is reached. If the spray pressure

is too high, throttle the centrifugal pump by closing down

the control valve.

Closed Center (Pressure Compensated) —

HM2C and HM4C models only

On a pressure compensated system the amount of oil that is

allowed to flow through the hydraulic motor is regulated by a

metering orifice in the pressure port adapter. Three different

sizesof orifices are supplied with the HM2C and HM4C model

pumps to allow flexibility in the flow required for individual

sprayer needs.

The smaller the orifice the less hydraulic oil goes through the

motor,sothepumpwillrunslowerandtheflowofliquidpumped

andthespraypressurewillalsobeless. Asthehydraulicoilflow

is increased (by installing a larger orifice), the amount of liquid

being pumped and the spray pressure is also increased.

Installing and Removing Metering Orifice

1. Shut off the hydraulic system.

2. Disconnect the line to the pressure port of the hydraulic

motor.

3. Remove the adapter from the motor using a 1-1/16''

wrench.