-3-

General Safety Information Continued

1. Always mount the pump with oil sight tube in the

upright position.

2. The correct type and size of hose are vital to good

performance:

a. Use good quality inlet hose, compatible with

fluids being pumped and with good elasticity

to reduce inlet water hammer or pulsation.

Be sure that the hose is not too rigid but

capable of operating at low vacuums without

collapsing. The diameter of the inlet hose

should be at least that of the pump inlet port

size and preferably one size larger if the inlet

line is longer than approximately 6 feet.

b. Use only approved high pressure hose on

the discharge side of the pump.

3. Most ports are provided with hose barb connections.

Use good quality hose clamps, and tighten securely.

NOTE: Use only pipe, fittings, accessories, hose, etc.

rated for the maximum pressure rating of the pump.

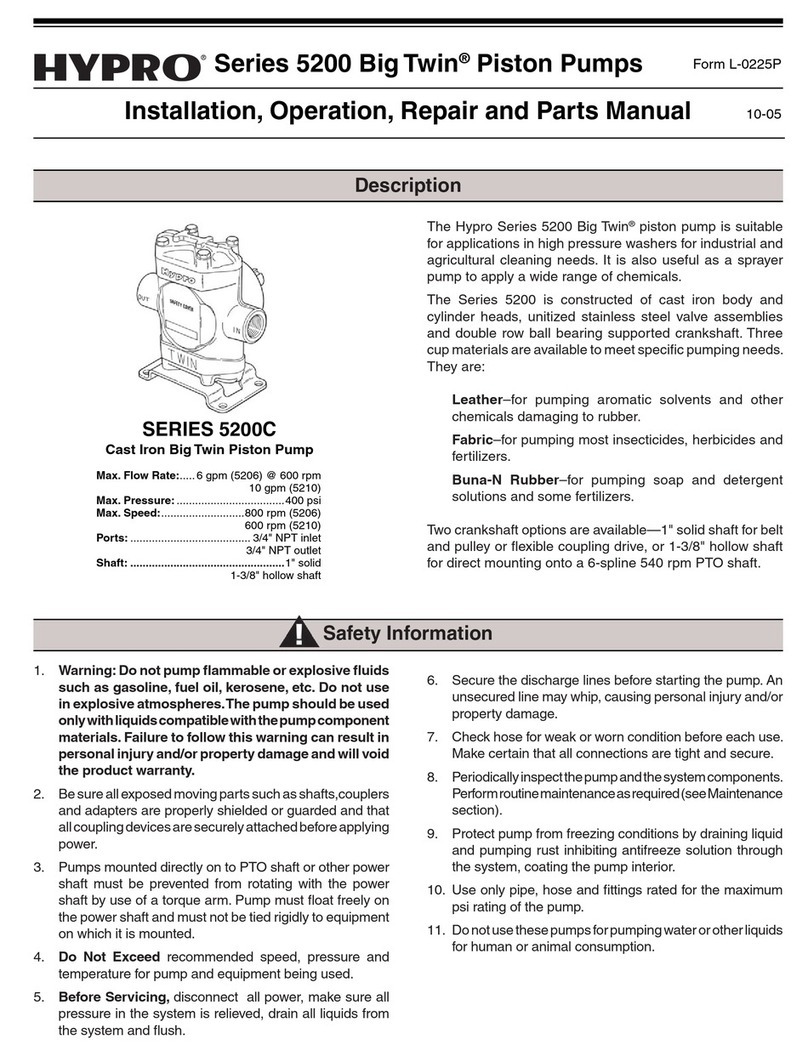

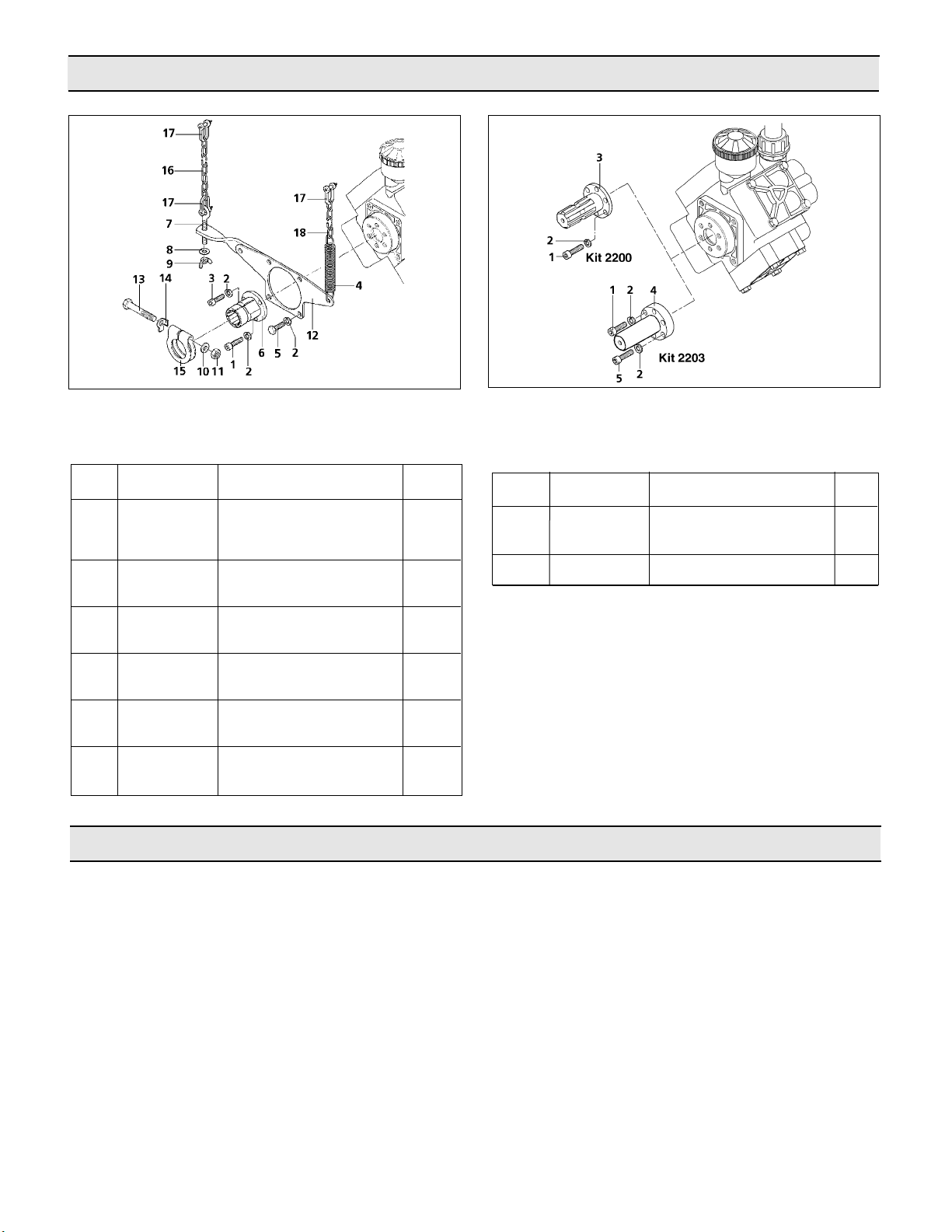

4. See the illustration for typical system hook-up.

The diagram shows necessary components and

accessories and their connections within the

complete system.

Agitation Line

Outlet

Control

Valve

Control

Valve

Or

Pressure

Gauge

To Spray Gun

To Boom Nozzles

Bypass Line

Tank

Shut-off

Strainer

Relief

Valve

Pump

Boom Shut-off

or Selector

Agitator

Pump Operation Instructions

Installation

Form L-1383 (12/11, Rev. B)

15. WARNING: Because of the risk of electrical

shock, all wiring should be done by a qualified

electrician.

WARNING: DO NOT handle a pump or pump

motor with wet hands or when standing on a wet

or damp surface, or while standing in water.

16. Do not operate a gasoline engine in an enclosed area.

Be sure the area is well ventilated.

17. Use only pipe, hose and fittings rated for the

maximum rated pressure of the pump or pressure that

the pressure relief valve is set. Check with a local

supplier for the proper pressure rating. Do not use

used pipe!

18. Do not use these pumps for pumping water or other

liquids for human or animal consumption.

19. Do not pressure feed pump inlet.

1. Be sure the oil is halfway up the clear oil sight tube. If

necessary,fill to the correct level with Hypro Oil

(Part Number 2160-0038). Hypro Oil is a specially

formulated, high-grade, nondetergent, SAE 30 weight

oil designed to prolong pump life.

2. Make sure the suction hose barb is tightly screwed onto

the suction union, and that there are no air leaks on the

inlet side of the pump.

3. Check the charge pressure on the pulsation dampener

before starting the pump. The pressure is checked with

astandard automotive air gauge. The pressure should

be at approximately 20% of your operating spray

pressure.

4. The relief valve bypass port should be connected back

to the liquid tank unrestricted. Do not hook the bypass

line back to the inlet port or inlet hose.

5. Always allow the pump to start under low pressure by

putting the pressure release lever in the pump position.

6. Start the pump and run for approximately one minute at

low pressure. Stop the pump and check the oil level in

sight glass. Oil should be halfway up the sight glass.

Add Hypro Oil (Part Number 2160-0038) if necessary.

7. Return the pressure release lever to the pressure

position and adjust the pump to the desired pressure by

changing the relief valve setting on the control unit,

relief valve, or unloader.