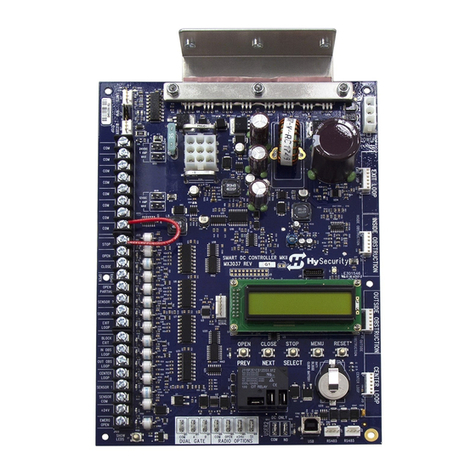

Smart Touch Controller Inputs...........................................................................................................................5-4

STC Terminal Inputs .................................................................................................................................................. 5-4

Setting the Emergency Fast Operate ....................................................................................................................... 5-6

Installing a Push-Button Device for EFO .................................................................................................................. 5-6

Connecting Accessories............................................................................................................................................ 5-7

User Relays – Programming Procedure ............................................................................................................. 5-8

Vehicle Detector Logic .................................................................................................................................... 5-10

Conguring the Vehicle Detector Logic and anti-TailGate Mode Selection........................................................... 5-10

Vehicle Detector Installation: HY-5A ...................................................................................................................... 5-12

Connecting HY-5A Vehicle Detectors ..................................................................................................................... 5-13

Dual Gate SyStemS ...............................................................................................6-1

Connecting an Interlocked Pair (Dual Gate) ............................................................................................................. 6-1

Dual Gate Wiring Connections ................................................................................................................................. 6-2

Dual or Sequenced Gates: Power, Software & Accessory Requirements

................................................................... 6-3

Programming a Dual Gate (Interlocked Pair) ........................................................................................................... 6-3

Connecting Sequenced Gates............................................................................................................................6-4

troubleSHootinG ..................................................................................................7-1

System Diagnostic Messages....................................................................................................................................... 7-1

Electrical Issues ............................................................................................................................................................ 7-6

AC-Powered StrongArm M30/M50 Operators ............................................................................................................ 7-6

Mechanical Issues......................................................................................................................................................... 7-6

Hydraulic Issues............................................................................................................................................................ 7-7

Typical Problems and Troubleshooting Procedures ..................................................................................................... 7-7

General Maintenance................................................................................................................................................... 8-1

Smart Touch Analyze and Retrieve Tool (S.T.A.R.T.) ..................................................................................................... 8-1

What You Need ............................................................................................................................................................ 8-1

Installing S.T.A.R.T. Software ........................................................................................................................................ 8-1

Installing S.T.A.R.T. Software, continued...................................................................................................................... 8-2

Setting User Account Controls..................................................................................................................................... 8-2

Electrical Controls ........................................................................................................................................................ 8-2

Mechanical Maintenance ............................................................................................................................................. 8-3

Hydraulic System Maintenance.................................................................................................................................... 8-3

M30/M50 Hydraulic Cylinder Maintenance ................................................................................................................. 8-4

M30/M50 Bearing Maintenance & Lubrication ............................................................................................................ 8-5

Clock Battery Replacement.......................................................................................................................................... 8-5

reference Section ................................................................................................ a1

M30/M50 WiringDiagram .......................................................................................................................................... A2

aPPenDix b .......................................................................................................... b1

Wire Sizing and Runs ................................................................................................................................................. B1

StrongArm M30/M50 Wiring Chart (Incoming Power)............................................................................................... B2