8000 SRM 970 General

General

This section contains a Maintenance Schedule and

the instructions for maintenance and inspection.

The Maintenance Schedule has time intervals for in-

spection, lubrication, and maintenance. The time

intervals are based on a normal operation. A nor-

mal operation is considered to be one 8-hour shift

per day in a relatively clean environment on an im-

proved surface. Multiple shifts, dirty operating con-

ditions, etc., will require a reduction in the recom-

mended time periods in the Maintenance Schedule.

WARNING

Do not make repairs or adjustments unless you

have both authorization and training. Repairs

and adjustments that are not correct can make

a dangerous operating condition.

Do not operate a lift truck that needs repairs.

Report the need for repairs to your supervisor

immediately. If repair is necessary, put a DO

NOT OPERATE tag on the control handle. Re-

move the key from the key switch.

Your lift truck dealer has the facilities and trained

personnel to do the maintenance. A complete pro-

gram of inspection, lubrication, and maintenance

will help your lift truck perform efficiently and oper-

ate over a longer period of time.

Some users have service personnel and facilities to do

the items listed in the Maintenance Schedule. Ser-

vice Manuals are available from your lift truck dealer

to help users who do their own maintenance.

Do not make repairs or adjustments unless specifi-

cally authorized to do so.

Put the lift truck on a level surface. Lower the car-

riage and forks, apply the parking brake, and turn

the key switch to OFF. Open the access panels and

inspect for leaks and conditions that are not normal.

Clean any oil spills. Make sure that lint, dust, paper,

and other materials are removed from the compart-

ments.

HOW TO MOVE DISABLED TRUCK

How to Tow Lift Truck

WARNING

Use extra care when moving a lift truck during

the following conditions:

• Brakes do not operate correctly.

• Steering does not operate correctly.

• Tires are damaged.

• Traction conditions are bad.

• The lift truck must be moved on a steep

grade.

If the steering pump motor does not operate,

steering control of the lift truck can be slow.

This can make the control of the lift truck dif-

ficult. If there is no electrical power, steering

can be difficult. Poor traction can cause the

disabled lift truck or towing vehicle to slide.

Steep grades will require additional brake

force to stop the lift truck.

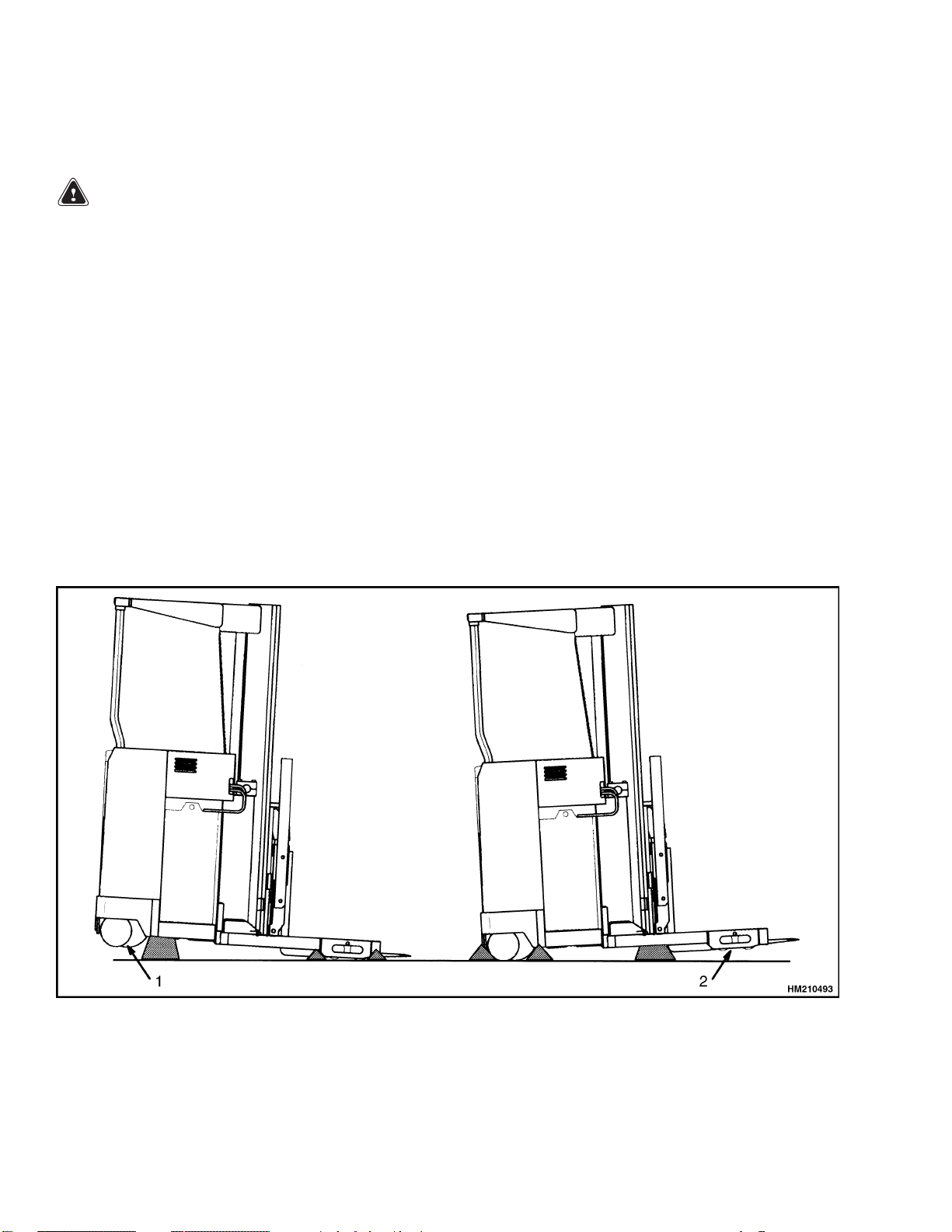

Never carry a disabled lift truck unless the lift

truck MUST be moved and cannot be towed.

The lift truck used to carry the disabled lift

truck MUST have a rated capacity equal to

or greater than the weight of the disabled

lift truck. The capacity must be for a load

center equal to half the width of the disabled

lift truck. See the nameplate of the disabled

lift truck for the approximate total weight.

The forks must extend the full width of the

disabled lift truck. Center the weight of the

disabled lift truck on the forks and be careful

not to damage the under side of the lift truck.

1. The towed lift truck must have an operator.

2. Tow the lift truck slowly.

3. Raise the carriage and forks approximately

30 cm (12 in.) from the surface.

4. If a counterbalanced lift truck is used to tow the

disabled lift truck, that lift truck must have an

equal or larger capacity than the disabled lift

truck. Install an approximate half-capacity load

on the forks of the lift truck that is being used

to tow the disabled lift truck. This half-capacity

load will increase the traction of the lift truck.

Keep the load as low as possible. Do not attempt

to tow a reach truck with another reach truck.

1