Hydraulic Gear Pump Repair 1900 SRM 97

DISASSEMBLE

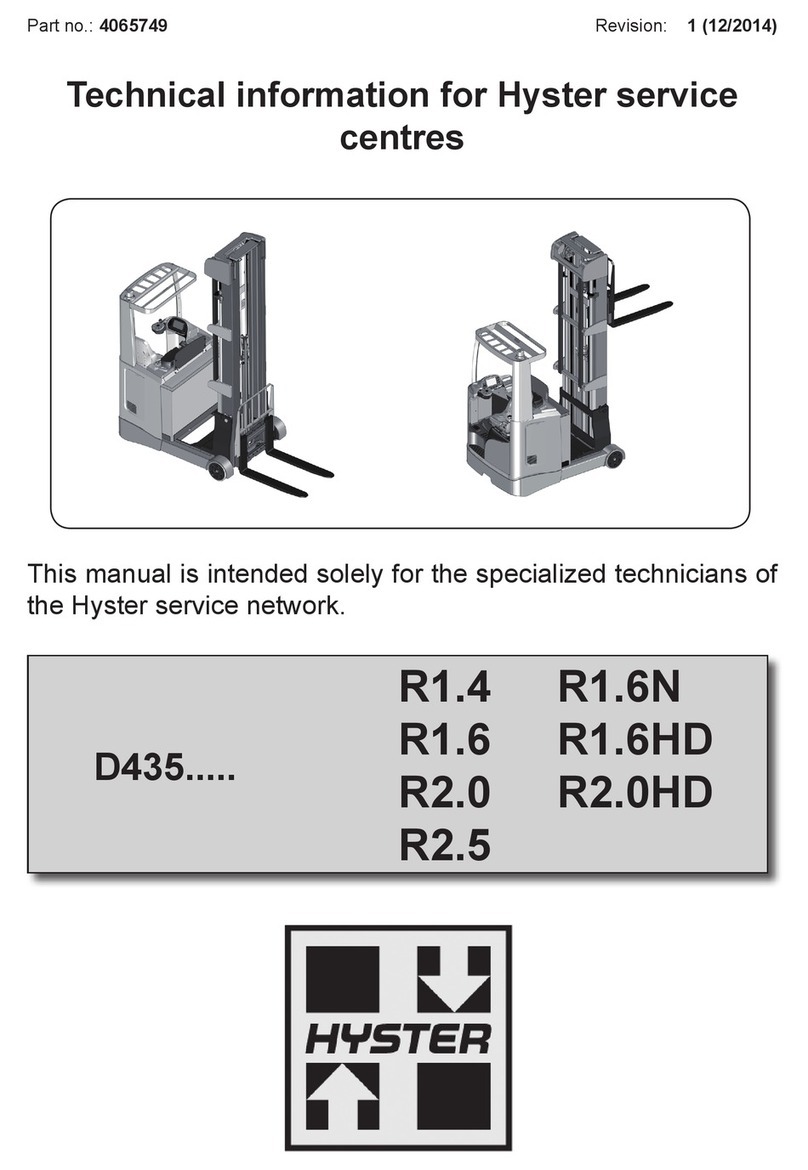

NOTE: SeeFigure6,Figure7,Figure8,orFigure9

for the illustration that is similar to the pump being

repaired. The illustration can have parts that are

different than those in the actual pump that is being

repaired.

1. Remove gear or sprocket from input shaft. If

equipped, remove pulley from input shaft. See

Figure 5.

NOTE: NOTALLLIFTTRUCKMODELSHAVEAPUL-

LEY ASSEMBLY ON THE GEAR PUMP.

1. PLATE

2. CAPSCREW

3. WASHER

4. LOCKWASHER

5. PULLEY

6. NUT

Figure 5. Pulley Assembly on Gear Pumps

2. Before disassembling the pump, make alignment

marks on all housings. Some housings can be as-

sembled in the wrong positions, which will cause

failure or increased wear. Carefully clean the

outside of the pump.

NOTE: The inlet ports in most gear pumps are larger

than the outlet ports.

NOTE: Ifthepumpisheldinavisefordisassembly,

makesurethevisedoesnotholdthepumptootightly

and cause distortion of the pump body.

NOTE: The position of the seals is important. In some

pumps the direction of pump rotation is changed by

changing the position of the seals and housings. The

holes in the seals must be aligned with the oil pas-

sages in the housing sections. The oil passage for the

thrust plates is in the outlet chamber.

Make sure you make careful notes of the location and

orientation of the parts and seals during disassem-

bly. Some of the parts are similar, but not exactly

thesameanditcanbedifficulttomakeanidentifi-

cation if they are mixed.

3. Remove capscrews or nuts that hold housings to-

gether. Use a plastic hammer to separate hous-

ings. Do not damage machined surfaces.

4. Remove gears and thrust plates (if used). Make

a note of the positions of the thrust plates, seals,

and gaskets. Do not use a punch to mark the

parts. Remove any springs and check valves.

5. Remove bearings with a puller. In some pumps,

the bearing blocks or plates must be replaced

with the bearings.

6. Remove front seal.

CLEAN

WARNING

Cleaning solvents can be flammable and toxic

and can cause skin irritation. When using

cleaning solvents, always follow the solvent

manufacturer’s recommended safety precau-

tions.

WARNING

Compressed air can move particles so they

cause injury to the user or to other personnel.

Make sure the path of the compressed air is

away from all personnel. Wear protective gog-

gles or a face shield to prevent injury to the

eyes.

CAUTION

Any dirt that enters the hydraulic system can

cause damage to the parts.

Clean all parts of the pump with solvent. Use com-

pressed air to dry the parts. Do not use a cloth to dry

the parts. Pieces of the cloth can cause restrictions in

thehydraulicsystem.Makesuretheworkareaand

tools are very clean.

4