INTRODUCTION

OPERATOR MANUAL 13

P20PS

14 OM-P20PS2019001-EN

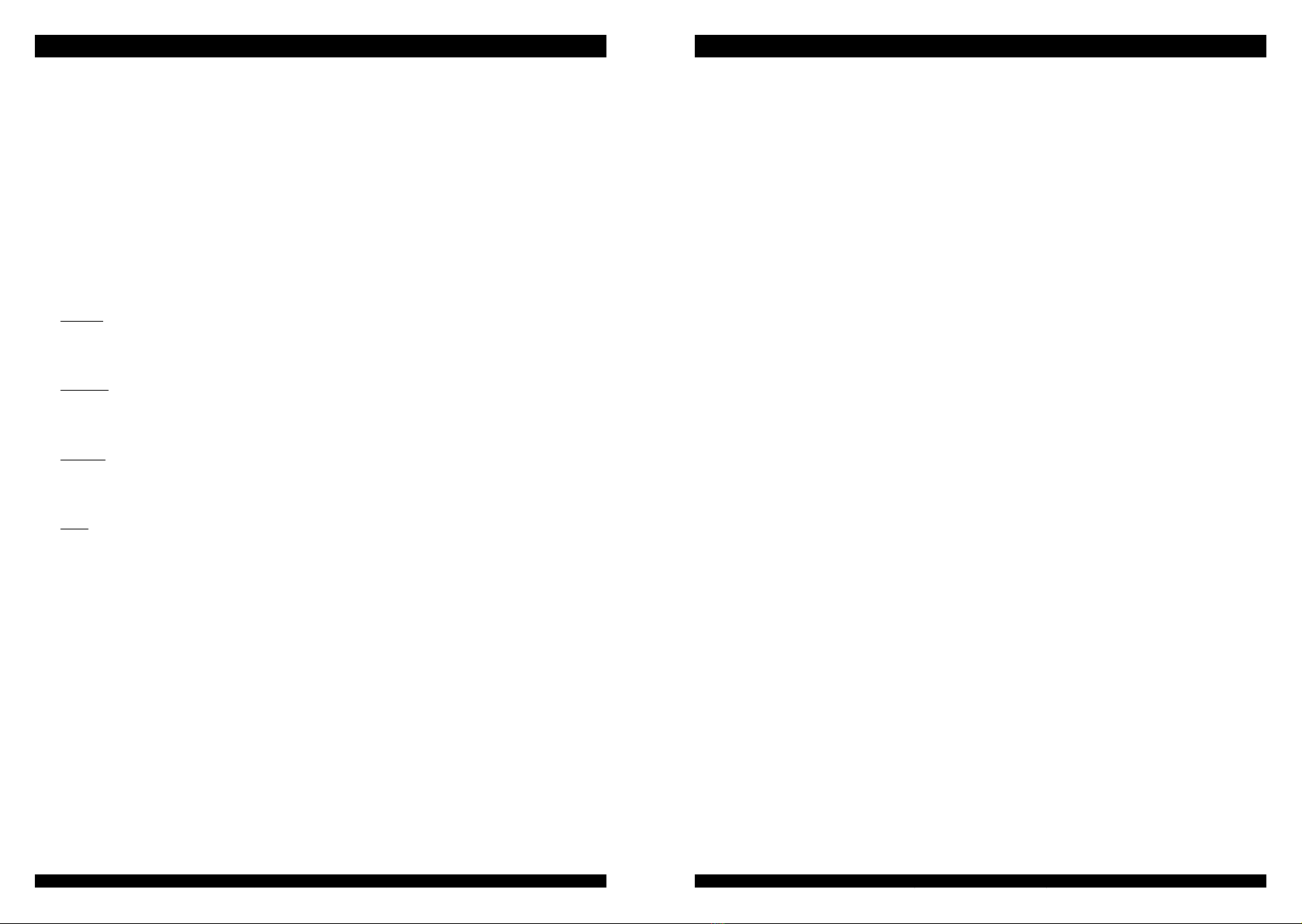

Technical Specifications

Identification

1.1 Manufacturer BYD BYD

1.2 Model P20PS-U P20PS

1.3 Power Electric Electric

1.4 Operating mode Stand-on Stand-on

1.5 Rated loading capacity Q (Kg) 2000 2000

1.6 Load center distance c (mm) 600 600

1.8 Axle centre to fork face x (mm) 966 1036

1.9 Track width (Max. fork height/Min. fork height y (mm) 1311/1373 1381/1443

Weight

2.1 Net weight kg 660 630

2.2 Axle load with load, drive/load side kg 1160/1500 1140/1490

2.3 Axle load without load, drive/load side kg 520/140 500/130

Wheel

3.1 Wheel type Polyurethane Polyurethane

3.2 Drive wheel size Φx w (mm) Φ230×75 Φ230×75

3.3 Load wheel size Φx w (mm) Φ85×110 Φ85×110

3.4 Caster size Φx w (mm) Φ100×50 Φ100×50

3.5 Wheels, number caster/load (X=number of drive

wheels) 1×+2/2(4) 1×+2/2(4)

3.6 Track width (front), drive side b10 (mm) 510 510

3.7 Track width (rear), load side b11 (mm) 370 505

Basic

Dimensions

4.4 Lift height h3 (mm) 120 120

4.9 Handle height when operating, Min./Max. h14 (mm) 970/1300 970/1300

4.15 Min. fork height h13 (mm) 85 85

4.19 Overall length l1 (mm) 1820/2290 1890/2360

4.20 Body length( to fork face ) l2 (mm) 670 670

4.21 Overall width b1 (mm) 726 726

4.22 Fork dimensions s/e/l (mm) 55×180×1150 55×180×1220

4.25 Width over forks b5 (mm) 685 685

4.32 Ground clearance m2 (mm) 25 25

4.34 Aisle width, 800x1200mm lengthwise Ast (mm) 1919/2403 1989/2473

4.35 Turning radius Ast (mm) 1680 1750

Performance

Data

5.1 Travel speed, with/without load km/h 9/12 6/6

5.2 Travel speed, with/without load mm/s 40/50 40/50

5.3 Lower speed, with/without load mm/s 50/40 50/40

5.8 Gradeability, with/without load %6/15 8/15

5.10 Service brake Electromagnetic Electromagnetic

Motor

6.1 Drive motor output kW 1.9 1.3

6.2 Lift motor output kw 1.2 1.2

6.4 Battery voltage/capacity kW 24/130 24/130

6.5 Battery weight (+/-5%) V/ Ah 70 70

Other 8.4 Sound level at driver's ear dB(A) 70 70

Working Environment

Temperature:-5 ~ 40°C

Working humidity:≤90%

Operating Altitude:≤2000m

Road: dry, hard, level and flat

Storage: in airy storehouse

Caution

If the working environment is harsh, decrease the goods or reduce the speed.

Danger

(1) No sharp obstacle.

(2) No strong acid or base on the road.

(3) Do not soak the tire in the water for a long time.

(4) Do not expose the truck to the burning sun.

(5) No flammable gas, no flammable dust and no volatile flammable liquid.

Note

Contact with your BYD local dealer if the forklift is intended to be used in the following

environments:

(1) in places where explosives are stored

(2) in dusty areas

(3) in ports or water front with corrosive salt hazards

(4) in chemical factories with acid and other chemical hazards

(5) in potential explosive environments with dust or other explosive gas

(6) in toxic environment

(7) in radioactive environment

(8) in other special environment