INTRODUCTION

USER MANUAL 8

EPS14Pi

9

INTRODUCTION

Thanks for your using BYD forklift.

The user manual is designed to show correct operation of BYD forklift and procedures related to

checkup, protection and maintenance thereof. Please refer to relevant chapters for more details.

Please read the user manual carefully before carrying out operation so as to op-erate and

maintain forklifts correctly. When a forklift is borrowed or transported, please make sure that

this manual is taken with operators so that it can be used at any time.

When you check the user manual, please note tips containing the following signs:

Danger

It indicates imminent danger. If not avoided, it may result in death or serious injury, or serious

property loss.

Warning

It indicates potential danger. If not avoided, it may result in death or serious injury, or serious

property loss.

Caution

It indicates potential danger. If not avoided, it may result in mild or moderate inju-ry, or some

property damage.

Note

It indicates tips of operation details. Obeying these tips of details can better your operation.

In order to avoid the inconvenience from the claim afterwards, please check whether the

functions and configuration of the forklift are complete.

DESCRIPTION

STATEMENTS

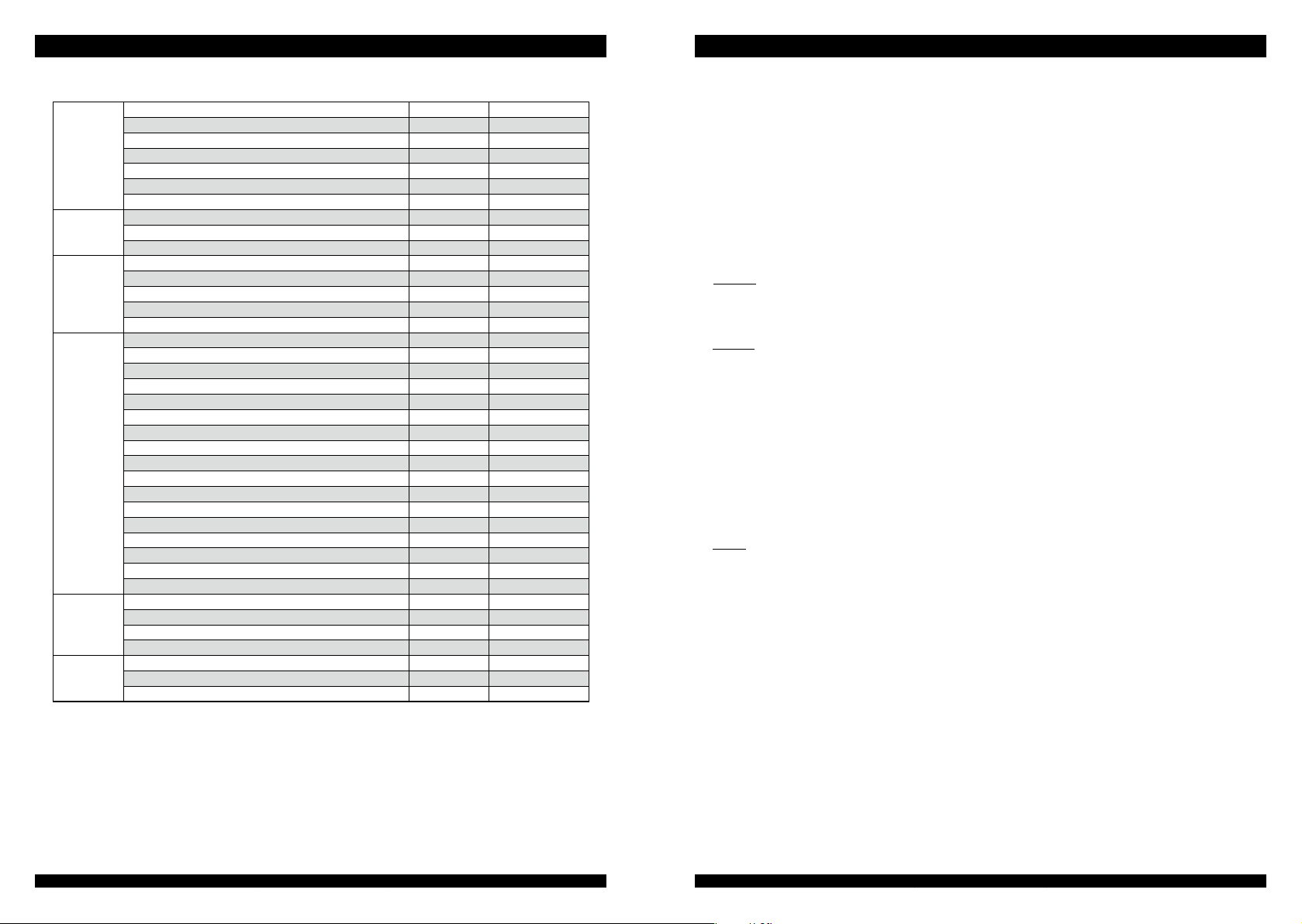

HAND OVER FORKLIFTS

Each certificated forklift has been performed a complete test for its functions in the factory, and

has been protected well during the transportation process. Despite all this, our company can’t

guarantee that the forklift is free of damage during the transportation process. Therefore, in order

to ensure the normal operation of the forklift, you shall inspect and accept carefully and shall be

obliged to re-inspect the following items when handing over the forklift:

1. Check tightness of the wheel nuts

2. Check the level of hydraulic oil

3. Check braking function

4. Check driving function

5. Check steering function

6. Check mast and operating function of accessories

7. Check whether high-voltage connection terminals of electric devices are loose.

The industrial forklifts produced by our company are solely used for available factory sites and

special areas allowed by Regulation on Special Equipment Safety Supervision.

All losses resulted from improper use shall be undertaken by users themselves, and our

company does not undertake any responsibility. If you need to use pur-chased forklift in a

special environment not mentioned in this manual, please negotiate with local dealers of BYD.

Without written permission of our company, any change on the forklift shall not be allowed. If

necessary, please negotiate with our company.

If the purchased forklift is equipped with other appliances beside fork, please load goods in

accordance with the loading nameplate thereof. All appliances are equipped with the user

manual, please read carefully.

This manual is made based on a standard forklift. If you have any doubt about the purchased

forklift, please be free to consult the after-sales personnel of BYD electric forklifts.

Our company will continuously develop products and constantly improve the design and

structures of products. Our company reserves the right to modify and interpret shape,

equipment, expertise and technical parameters.Our company shall not accept any appeal based

on the technical indicators, pattern and specifications in this manual.

OM-EPS14Pi2019001-

E

N