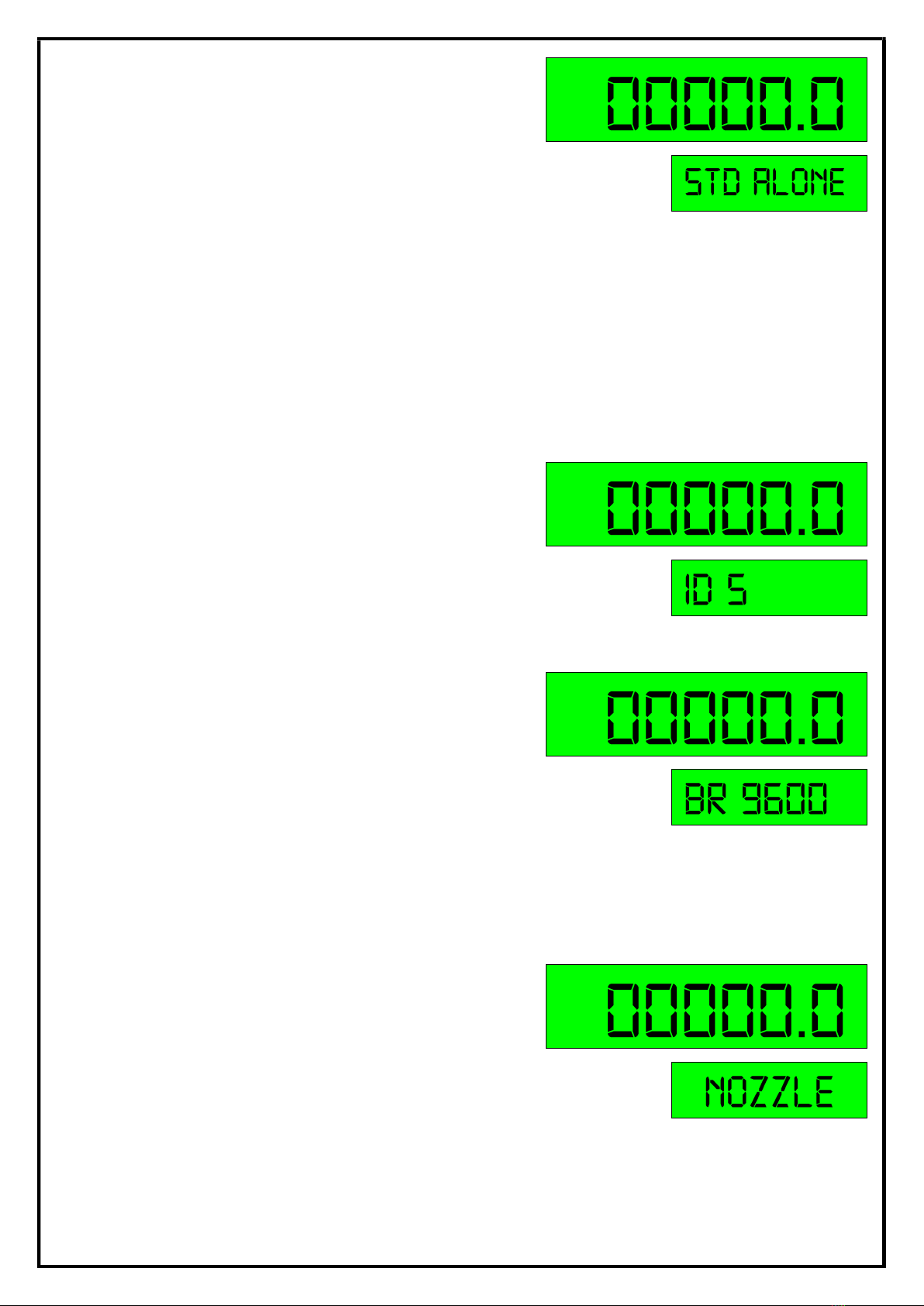

S902/3

ELECTRICAL

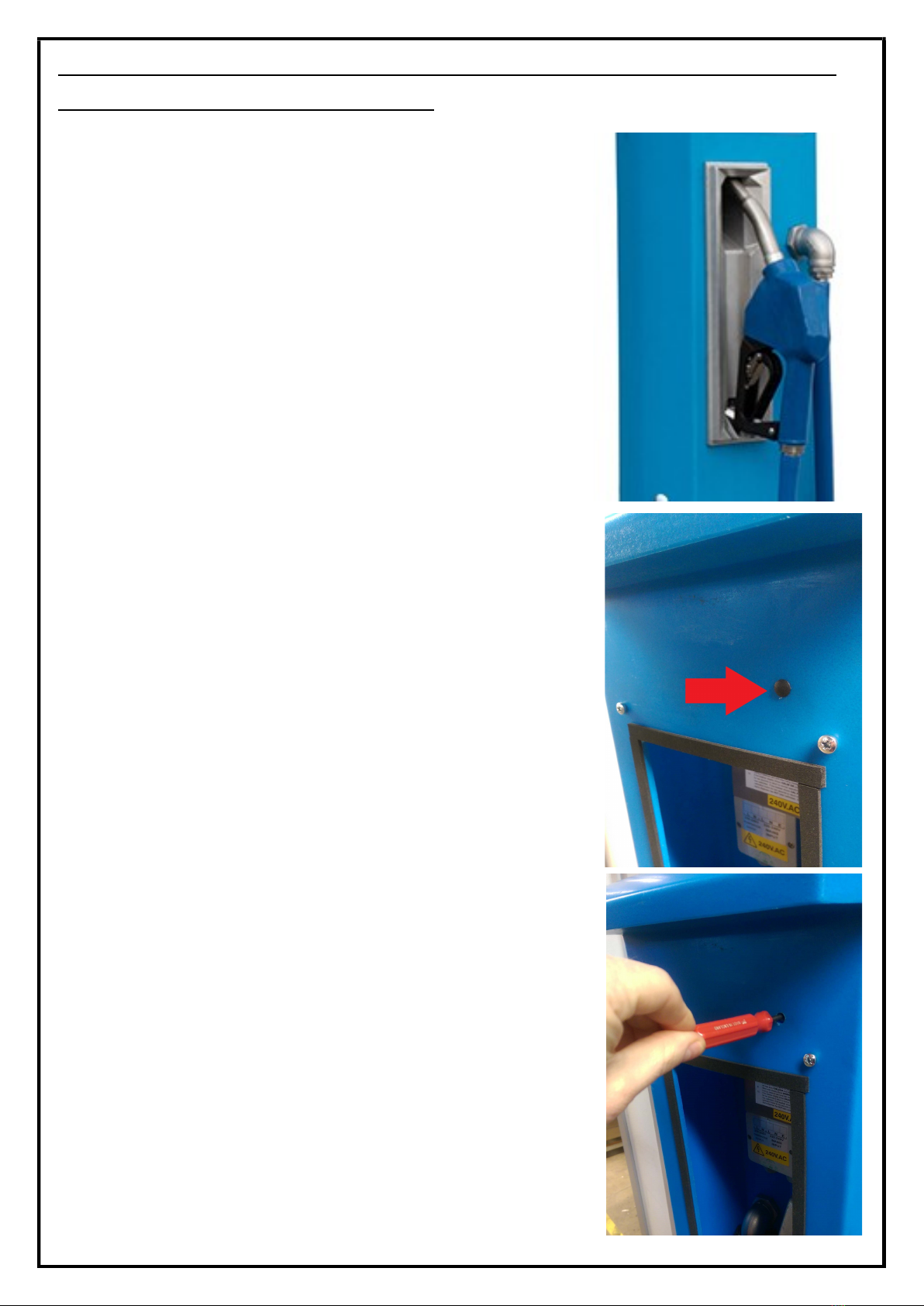

7. Remove the cover from the 220/240V junction box.

8. Connect a constant 220/240V AC 50 Hz supply, fused at 10

amps, to the terminal block in the 220/240V supply junction box

as shown on the wiring details diagram.

NB: The dispenser must have a continual 220/240V AC

supply, even when not in use

9. A 230VAC switched motor supply rated at 10 Amps max. is

provided, to control a remote pump, motor or relay, at the

terminals labelled 230V PUMP/MOTOR OUTPUT.

10. A 12VDC switched solenoid valve supply rated at 8 W max is

provided, to control a remote solenoid valve or relay, at the

terminals labelled 12v SOLENOID OUTPUT.

11. If the dispenser is to be operated in conjunction with a fuel

control key/card system then there are two options:

SINGLE DISPENSER SETUP. The fuel control system can

interrupt/switch the live feed to the pump/motor connected to

the pedestal.

MULTI DISPENSER SETUP. Solenoid valves will need to be

fitted to the inlet feed to each dispenser. The fuel control

system can interrupt/switch the live feed to the solenoid valve

connected to each pedestal.

Make connection – Pump running

Break connection – Pump not running

12. A pulse output for connection to fuel control key/card systems

is available from the separate terminals located on the display

circuit board. This is a passive contact giving 10 or 100 pulses per

litre. Contact ratings are as follows:

Maximum current - 0.25 amps

Maximum voltage - 50 volts

Maximum power - 5 VA