Only operate the machine in open space (e.g. not close to a wall or other fixed

object) and on a firm, level surface;

Do not operate the machine on a paved or gravel surface where ejected

material could cause injury;

Before starting the machine, check that all screws, nuts, bolts, and other

fasteners are properly secured and that guards and screens are in place. Replace

damaged or unreadable labels;

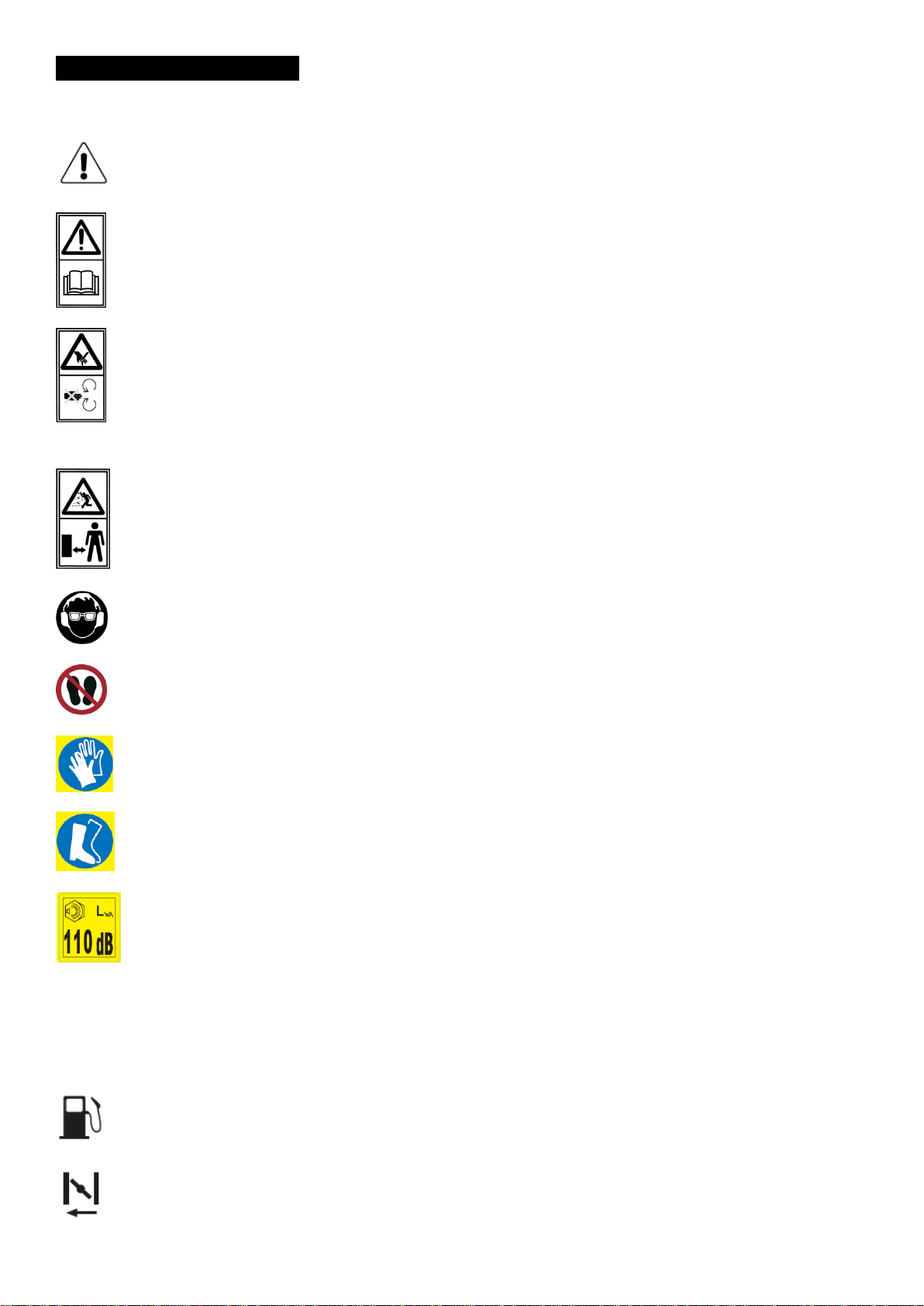

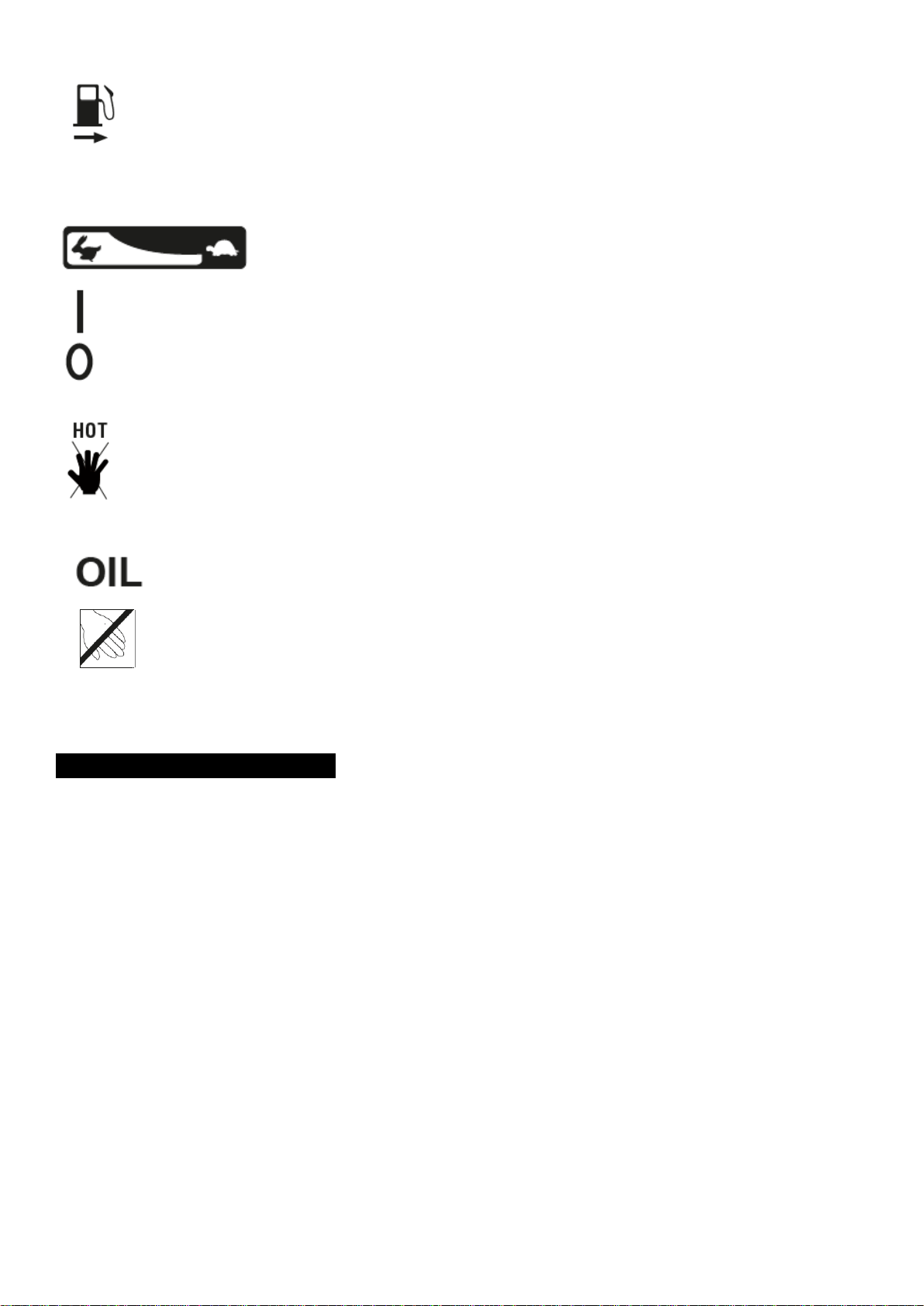

Use extra care in handling fuels. They are flammable and the vapors are

explosive. The following points should be observed:

use only an approved container;

Never remove the fuel cap or add fuel with the power source running. Allow

engine and exhaust components to cool before refueling;do not smoke;

Never refuel the machine indoors;

Never store the machine or fuel container inside where there is an open flame,

such as a water heater;

If fuel is spilled, do not attempt to start the power source, but move the

machine away from the area of spillage before starting;

Always replace and securely tighten the fuel cap after refueling;

If the fuel tank is drained, this should be done outdoors.

Operation

1) Before starting the machine, look into the feeding chamber to make certain that it

is empty;

2) Keep your face and body away from the feed intake opening;

3) Do not allow hands or any other part of the body or clothing inside the feeding

chamber, discharge chute, or near any moving part;

4) Keep proper balance and footing at all times. Do not overreach. Never stand at a

higher level than the base of the machine when feeding material into it;

5) Always stand clear of the discharge zone when operating this machine;

6) When feeding material into the machine be extremely careful that pieces of

metal, rocks, bottles, cans or other foreign objects are not included;

7) If the cutting mechanism strikes any foreign objects or if the machine should start

making any unusual noise or vibration, shut off the power source and allow the

machine to stop. Disconnect the spark plug wire from the spark plug (electric unit

disconnect from supply) and take the following steps:

Inspect for damage;

2