INSTALLATION & OPERATION MANUAL

L500 Series

-1-

TABLE OF CONTENTS

ABOUT THIS MANUAL ………………………………………………………………..…….....………..

SAFETY PRECAUTIONS ………………………………………………………….……..………………

APPROXIMATE CONVERSIONS FROM STANDARD………………………………………………

CHAPTER 1 ENGINE OVERVIEW ……………………………………………..…...….…….………

ENGINE COMPONENTS ………………………………………..……….……………

TECHNICAL DATA ………………………………………………..…….……………..

PERFORMANCE CURVES…………………………………………….………..……..

ENGINE IDENTIFICATION……………………………………..……….………….....

ENGINE SUSPENSION.…………………………………………….……..……...........

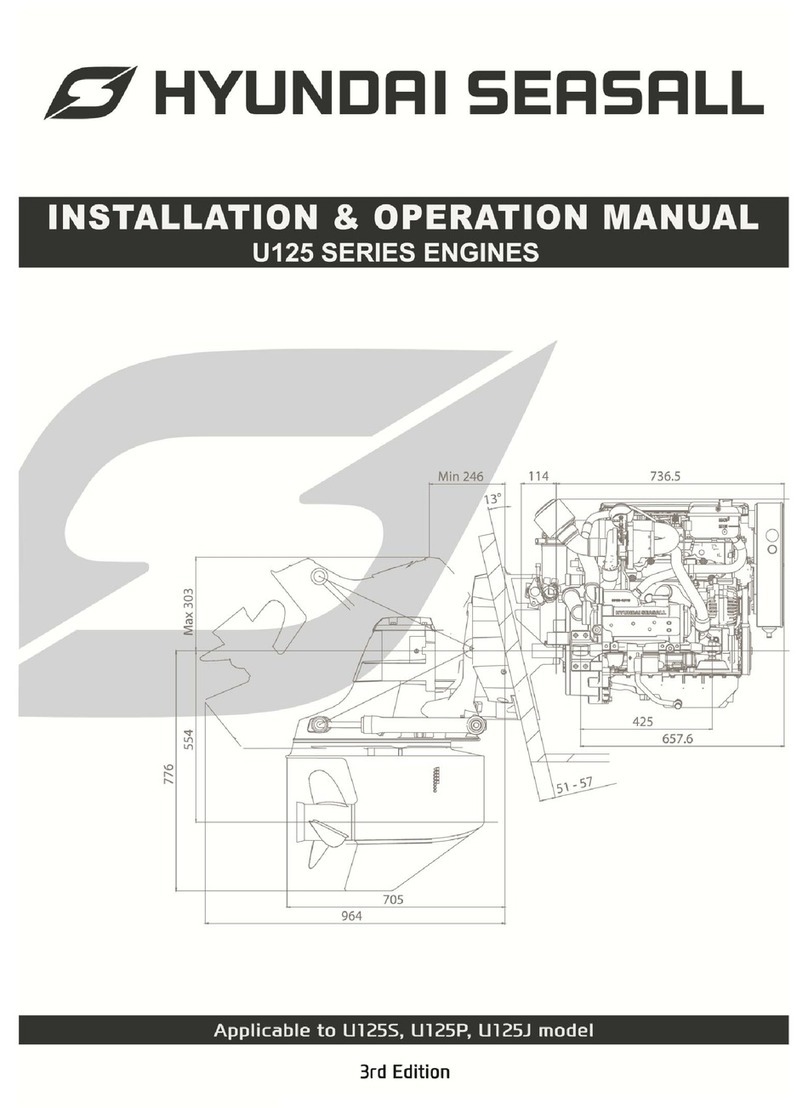

ENGINE DIMENSIONS………………………………………….………..….....……..

CHAPTER 2 ENGINE OPERATION ………………………………………………………….………..

STARTING AND STOPPING ENGINE……………………………..…..…………….

EMERGENCY STOP …………………..………………………………..….…………..

INTAKE AIR HEATER………………………………………………………….………..

CHAPTER 3 COOLING SYSTEM …………………………………………………………..….……...

SCHEMATIC DIAGRAM OF ENGINE COOLING CIRCUIT ……..…....................

SEAWATER FLOW –OPEN COOLING CIRCUIT…………………...……….…….

WATER PICKUP……………………………………………………..…….…….……..

WATER STRAINER…………………………………………………..…….……..…….

CLEANING STRAINER FILTER……………………………………..……….…..………

AUTOMATICDRAIN VALVE..……………………………………………...…..………

SEAWATER PUMP………………………………………………………...…..………

CHECKING SEAWATER PUMP & IMPELLER………………………………..……..

ENGINE COOLANT FLOW……………………………………………….…………….

ENGINE COOLANT………………………………………………………..…….…….

SUPPLEMENTAL ENGINE COOLANT………………………………….……….….

DRAINING COOLANT……………………………………………………..…….…….

REMOVING AIR BUBBLES IN COOLANT………………………………...….……..

CABIN HEATER CONNECTION……………………………………………..…..……

CHAPTER 4 FUEL SYSTEM ………………………………………………………….………………..

EUI SYSTEM…………………………………………………………………..………..

FUEL SUPPLY SYSTEM.….……..…………………………..…………….…….…...

FUEL LINE…………………....………………………………………………..…...……

RECOMMENDED FUEL QUALITY ………………....……………………..……..….

DRAINING WATER FROM FUEL FILTER ………………………………………..….

CHANGING FUEL FILTER ……………………………..……………….…….………..

CHAPTER 5 INTAKE & EXHAUST SYSTEM …………………………………………..….………..

ENGINE ROOM VENTILATION …………………………………………....……......

CHECK AIR FILTER ……………………………………..…………..……..….……..

CLEANING AIR FILTER ……………………………………..……………….….……

EXHAUST SYSTEM…………………………………………………..……..…………

CHAPTER 6 LUBRICATION SYSTEM …………….………………………….………….…………

LUBRICATION COMPONENTS……………………….…………………..…………

ENGINE OIL LEVEL CHECKS…………………….....……………….…….………..

3

4

6

7

7

9

10

11

12

13

15

15

16

16

17

17

17

18

18

19

20

21

22

22

23

23

24

25

25

26

26

27

27

28

28

29

30

31

31

31

32

33

33

34