I-Gard mGARD-100 User manual

C-419EM Instruction Manual, March 2015

Ground fault relay

microprocessor-based relay

mGARD-100

I-Gard’s commitment to electrical safety provides both industrial and commercial

customers with the products needed to protect their electrical equipment and the

people that operate them.

As the only electrical-safety focused company whose product portfolio includes

neutral grounding resistors, high-resistance grounding systems and optical arc

mitigation, we take pride in our technologies that reduce the frequency and

impact of electrical hazards, such as arc flash and ground faults.

For those customers who have purchased from us over the last 30 years, you

know us for the quality and robustness of our products, our focus on customer

service and technical leadership. We build on this foundation by investing

in developing new products in electrical safety education - including EFC

scholarship program - by actively participating in the IEEE community programs

on technical and electrical safety standard, and working with local universities

at discovering new technologies. We remain unrelenting in our goal of improving

electrical safety in the workplace.

Our commitment to excellence is validated by long-standing relationships with

industry leaders in fields as diverse as petroleum and gas, hospitals, automotive,

data centers, food processing, aerospace, water and waste water plants, and

telecommunications. We provide our customers with the product and application

support required to ensure that their electrical distribution system is safe and reliable.

ABOUT I-GARD

SUBJECT PAGE

1. Features ........................................................................................................................................... 2

2. Introduction ..................................................................................................................................... 2

3. Operation ......................................................................................................................................... 3

3.1 Operation and Glossary of Terms .......................................................................................... 3

Auto Reset: ............................................................................................................................... 3

Chassis Ground: ....................................................................................................................... 3

Interposing Current Sensor: .................................................................................................... 3

Failsafe: ..................................................................................................................................... 3

Non-Failsafe: ............................................................................................................................ 4

Manual Rreset: ......................................................................................................................... 4

3.2 Dipswitch Settings .................................................................................................................. 4

3.3 Indication ................................................................................................................................. 6

mGard-Sym Remote Indicator ................................................................................................ 6

3.4 Reset ........................................................................................................................................ 7

3.5 Ground Fault Test .................................................................................................................... 7

4. Installation Instructions .................................................................................................................. 8

4.1 Mounting .................................................................................................................................. 8

4.2 Built-In Current Transformer ................................................................................................... 9

4.3 Interposing Current Sensor .................................................................................................. 10

4.4 Connections ........................................................................................................................... 12

5. Catalogue Numbers .......................................................................................................................12

6. Service ............................................................................................................................................12

7. Technical Specifications ............................................................................................................... 13

8. Dimensional Drawings .................................................................................................................. 14

TABLE OF CONTENTS

1. FEATURES

• WIDE RANGE OF TRIP LEVEL SETTINGS AND TRIPPING TIME DELAYS

• CAN BE USED WITH INTERNAL OR INTERPOSING EXTERNAL CURRENT SENSOR

• WIDE RANGE AC AND/OR DC CONTROL VOLTAGE

• CONNECTS TO MGARD-SYM REMOTE INDICATOR

-MODBUS CONNECTION TO EXTERNAL NETWORK

-REMOTE DATA COLLECTION

-REMOTE RELAY RESET

-MONITORS UP TO 50 DEVICES ON A SINGLE MODBUS ADDRESS

-ISOLATION PROTECTS YOUR NETWORK

2. INTRODUCTION

The mGARD-100 is a microprocessor-based ground fault relay designed and built to be used on solidly grounded or

resistance grounded systems. This innovative digital electronic relay measures ground fault current using a built-in

2‘’ zero sequence current sensor (ZSCS).

The mGARD-100 reacts to alternating current only and will reject direct current signals. Harmonic ltering can be

enabled using a DIP switch. With the harmonic filtering feature enabled, the mGARD-100 rejects all frequencies

except the fundamental. This can be used to eliminate false tripping when using the relay on systems with

variable frequency drives. With the harmonic filter disabled, the relay will accurately respond to AC currents

between 25 and 400Hz.

By using an interposing current sensor, running the secondary through the mGARD-100 internal ZSCS, the

mGARD-100 can be applied on any system voltage.

The mGARD-100 relay is also available with low voltage DC power supplies including 5V, 12V, 24V and 48V DC.

Other specific ratings are available upon request; please consult I-Gard if other ratings are required.

The output relay has Form “Z” (4 terminal) Normally Open (N.O.) and Normally Closed (N.C.) contacts which may

be used to operate the upstream protective device and to indicate a ground fault in the system. The relay can be

set to operate in any one of the following modes: failsafe; non-failsafe; or auto reset by means of front-accessible

DIP switches.

By double clicking the test/reset button on the unit, a functional test of the mGARD-100 is invoked. A single press of

the remote test/reset button resets the relay after a trip. (It is not necessary to press the test/reset button to invoke

auto reset).

The green LED indicates two functions: When slow ashing it means control power is applied to terminals N- and L+;

when fast blinking it denotes the relay has sensed a ground fault current higher than the trip level threshold selected

for a period longer than the tripping time delay and that the output contacts have operated.

The mGARD-100 operates on any control voltage from 40 to 240V AC or DC, and contains an isolated power supply.

The seven position terminal block is pull-apart type that eases the wiring in the field.

A three position, pull-apart terminal connects the relay to the mGARD-SYM remote indicator (with modbus

connectivity) for remote test / reset and monitoring.

Special consideration must be taken in the selection of the neutral grounding resistor in a high resistance grounded

system as the capacitance-to-ground charging current on a system will vary depending on: the overall length of the

cables; the types of loads; the quality of insulation on the phase conductors; the surrounding equipment grounding,

cable trays, junction boxes, the type of sensor, etc. A “Rule-of-Thumb” for systems 600V and lower: The charging

current is 0.5 Amps per 1000 kVA of sensor capacity. In electrical systems of 600V and below it is common to use a

5 Ampere continuous rating for the neutral grounding resistor and setting the pickup current at 20% of that value (1

Ampere) for all relays and coordinating between upstream and downstream relays by selecting different time delays.

3. OPERATION

3.1 OPERATION AND GLOSSARY OF TERMS

Auto Reset:

After a trip, the relay will automatically reset itself three seconds after the ground fault current drops below the trip

current set point. The auto reset feature can be used in both failsafe and non-failsafe modes.

Chassis Ground:

Chassis ground is the ground to which all of the non-current carrying metal equipment is connected/bonded.

Typically, equipment grounding is provided by means of a ground bus. A solid connection is to be made from

terminal 7 of the mGARD-100 to the nearest chassis ground to ensure the relay complies with the specified

electromagnetic compatibility (EMC) standards. If using an external zero sequence current sensor, do not ground

any of the ZSCS secondary wires.

Interposing Current Sensor:

Interposing Zero Sequence Current Sensors (ZSCS) are required for any of the following applications:

• The ground fault trip current setting levels are higher than the 30 mA –12 Amp range available with the built-in

2” ZSCS.

• The size of the power conductors on which the mGARD-100 is being applied is too large for the 2” built-

in ZSCS.

• The system primary phase current on which the mGARD-100 is being applied exceeds 250 Amps continuous.

Failsafe:

The output relay changes state when control power is applied to terminals N- & L+. The N.O. contact closes and

the N.C. contact opens. When a trip occurs or control voltage is removed, the N.O. contact is opened and the N.C.

contact is closed.

Non-Failsafe:

The output relay does not change state when control power is applied to terminals N- & L+. When a trip occurs the

N.O. contact is closed and the N.C. contact is opened.

Ground (Earth):

The conductive mass of the earth, at which point all the exposed conductive parts of the system should be bonded

at a conventional voltage value of zero.

Ground Fault:

A ground fault is understood to be an accidental contact between a live conductor at phase potential and ground.

Manual Reset:

A N.O. contact RESET pushbutton located on the relay must be pressed once to reset the output relay after a trip,

providing the ground fault has been cleared.

Pickup Current / Trip Levels:

The value of the zero sequence (fault) current at which the relay is set to trip (the relay contacts change their state).

Time Delay:

Intentional period of time programmed to elapse before the tripping (operation) of the relay. It should not be confused

with the breaking (opening) time of the protection device.

Zero Sequence Current:

A vector summation of all electrical currents in an electrical line. Theoretically in any electrical system the summation

of all the electrical currents is zero. When the resulting summation value is other than zero it is an indication of a

current leakage to ground.

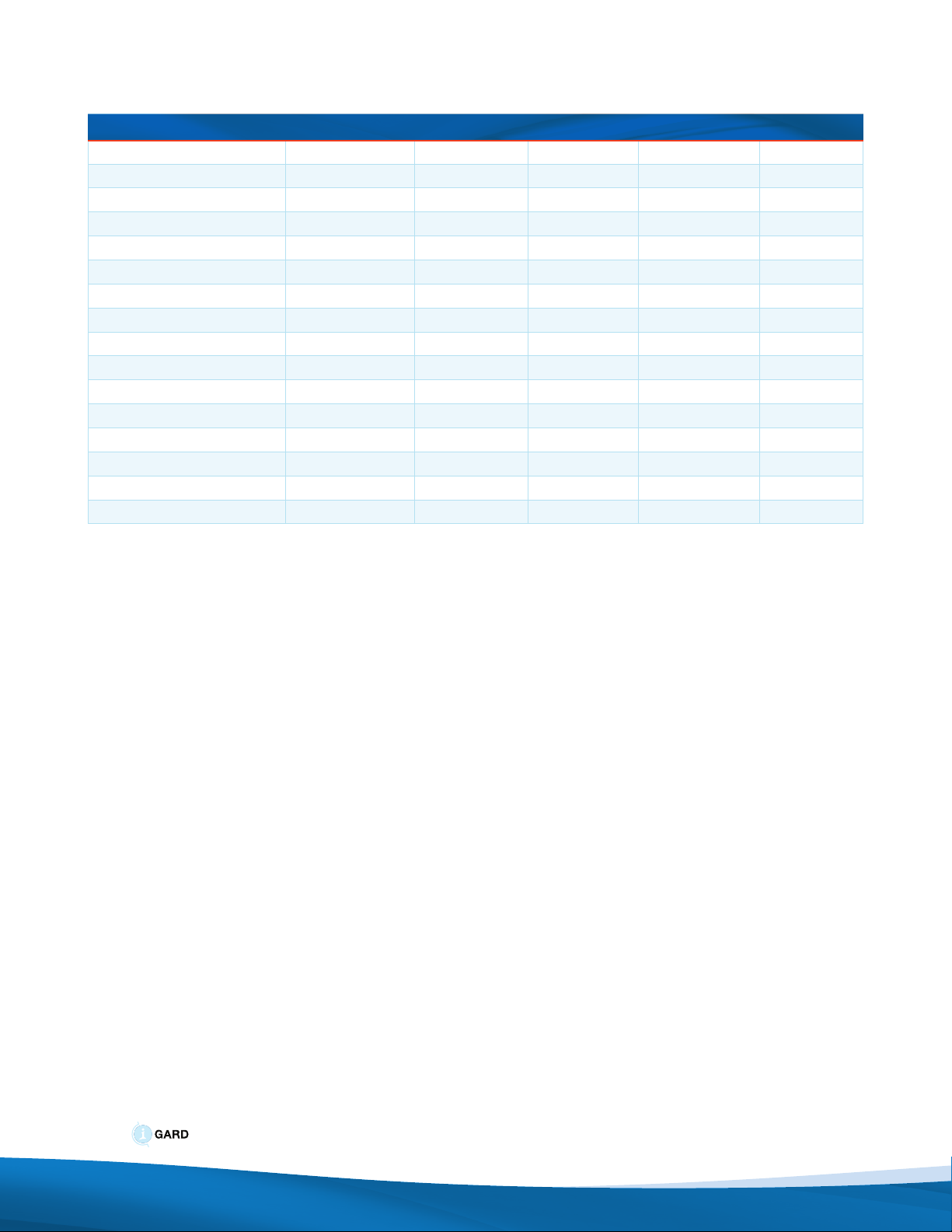

3.2 DIPSWITCH SETTINGS

The DIP switches are mounted inside of the relay and are accessible through the front cover. It is recommended that

all of the DIP switches be set at one time and before energizing the relay.

Changes to the DIP switch settings when the mGARD-100 relay is energized may be performed without having any

adverse effect on the relay. Table 3.0 displays all DIP switch selectable options.

Table 3.0 mGARD-100 DIP switch settings

(In the table above ‘R’ denotes right and ‘L’ denotes left

1Harmonic Filter L

R

Disabled

Enabled

2Trip Contacts L

R

Non-Failsafe

Failsafe

3Auto Reset L

R

Disabled

Enabled

4, 5, 6, 7

Ground Fault

Trip

Current Limit

Internal ZSCS 100:1 Interposing 1000:1 Interposing

L L L L

L L L R

L L R L

L L R R

L R L L

L R L R

L R R L

L R R R

R L L L

R L L R

R L R L

R L R R

R R L L

R R L R

R R R L

R R R R

30

40

60

90

150

250

400

600

900

1500

2500

4

6

9

10

12

3

4

6

9

15

25

40

60

90

150

250

400

600

900

1000

1200

30

40

60

90

150

250

400

600

900

150

250

4000

6000

9000

10000

12000

8, 9, 10 Trip Time Delay

L L L

L L R

L R L

L R R

R L L

R L R

R R L

R R R

20 milliseconds

50 milliseconds

100 milliseconds

200 milliseconds

500 milliseconds

1 second

2 seconds

5 seconds

SWITCH MEANINGFUNCTION SET TO

-Factory Setting

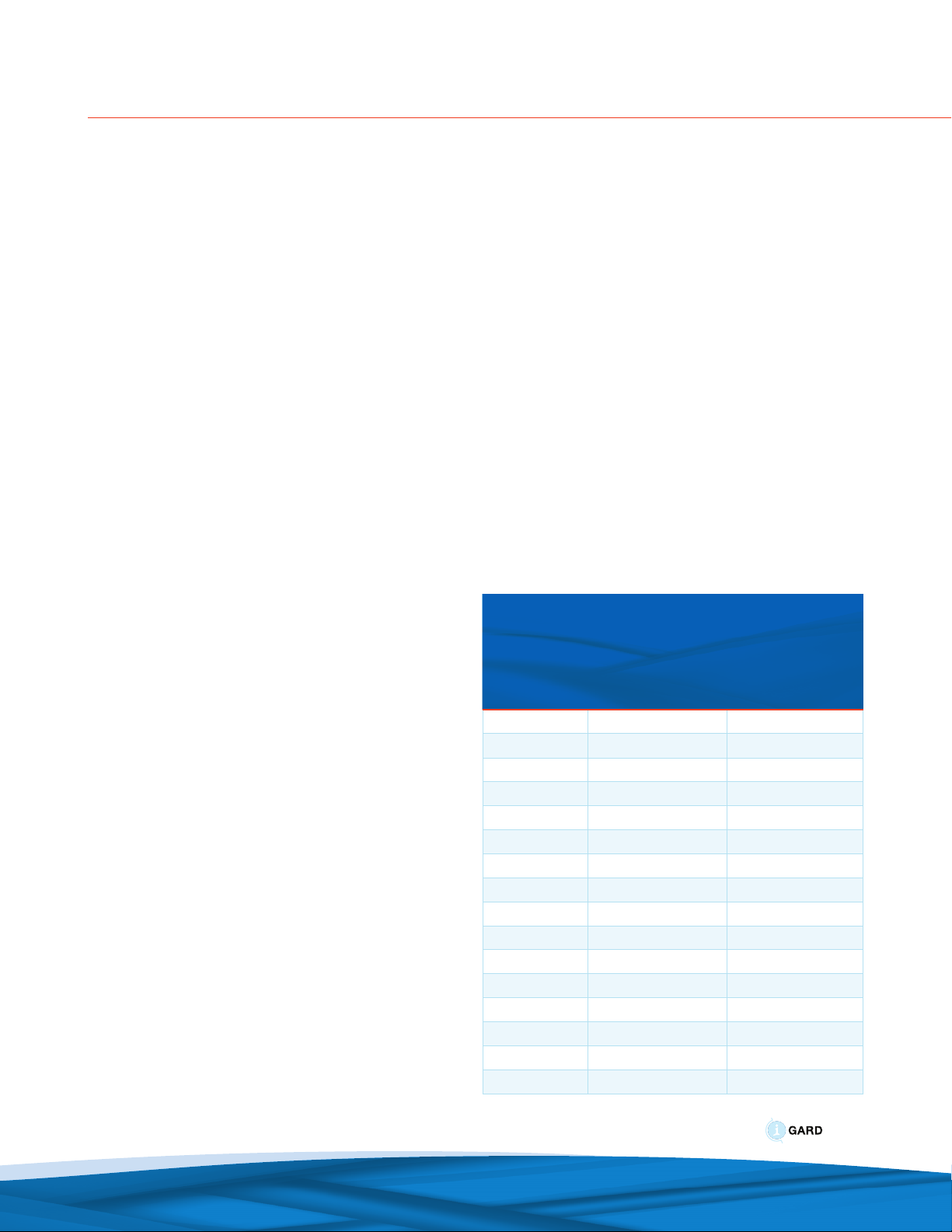

Trip levels can be scaled down by adding turns through the current sensor. Tables 3.1 display the trip levels with

multiple turns through the ZSCS.

Table 3.1 mGARD-100 Trip Levels vs. Turns through ZSCS.

30mA (L, L, L, L) 30mA 15mA 10mA 2.5mA 2mA

40mA (L, L, L, R) 40mA 20mA 14.3mA 5mA 4mA

60mA (L, L, R, L) 60mA 30mA 20mA 7.5mA 6mA

90mA (L, L, R, R) 90mA 45mA 30mA 12.5mA 10mA

150mA (L, R, L, L) 150mA 75mA 50mA 25mA 20mA

250mA (L, R, L, R) 250mA 125mA 83.3mA 30mA 24mA

400mA (L, R, R, L) 400mA 200mA 133.3mA 37.5mA 30mA

600mA (L, R, R, R) 600mA 300mA 200mA 52.5mA 42mA

900mA (R, L, L, L) 900mA 450mA 300mA 75mA 60mA

1500mA (R, L, L, R) 1500mA 750mA 500mA 125mA 100mA

2500mA (R, L, R, L) 2500mA 1250mA 833.3mA 150mA 120mA

4A (R, L, R, R) 4A 2A 1.33A 250mA 200mA

6A (R, R, L, L) 6A 3A 2A 600mA 480mA

9A (R, R, L, R) 9A 4.5A 3A 750mA 600mA

10A (R, R, R, L) 10A 5A 3.33A 1.05A 840mA

12A (R, R, R, R) 12A 6A 4A 1.5A 1.2A

DIP SETTING 1 TURN 2 TURNS 3 TURNS 4 TURNS

-Applies to both internal and external CT

5 TURNS

3.3 INDICATION

There is one green LED on the front of the mGARD-100:

LED Off: No control voltage or mGARD-100 defective

LED Slow Flashing: Normal, control voltage on

LED Fast Blinking: Ground Fault Trip

LED Steady On: Control voltage too low or mGARD-100 defective

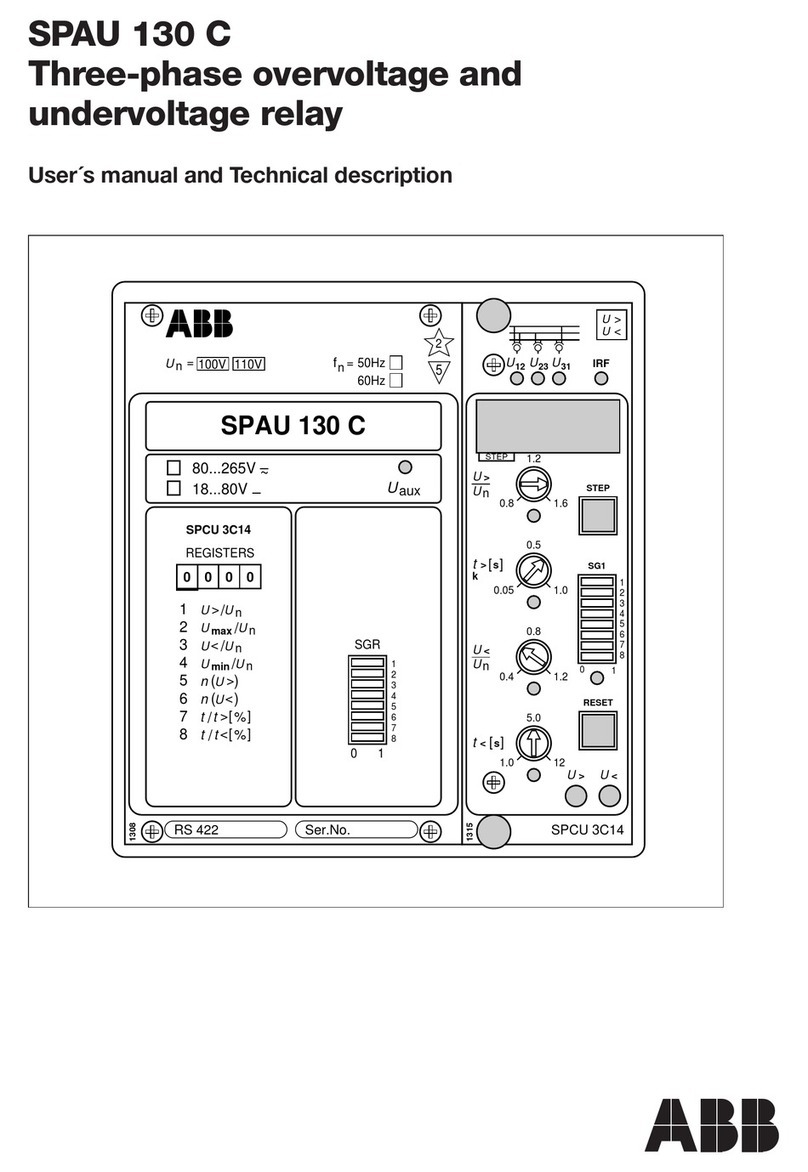

MGARD-SYM REMOTE INDICATOR

The mGARD-SYM is a remote display indicator that is used in conjunction with I-Gard relays. The indicator has the

capability to interconnect and work with up to 50 relays including the mGARD-100 relay in a bus network topology

and provides detailed device status information.

As shown in Figure 3.0, the display has a 4-line screen that shows a list of connected devices. A device can be

selected and viewed in detail. The relay mode, delay and trip level settings can be viewed (but not altered). The reset

and test functions can also be performed directly from the display.

Fault levels are displayed as a percentage of the selected pickup (trip) current level. If the trip level is 1 Amp

and there is a 500 mA fault current, the reading on the display will appear as 50%. Screen navigation is done

using a 4-button interface. The menus are displayed on the right side of the LCD; the left side is reserved for

viewing relay information.

To properly display current levels on the mGARD-SYM, the trip levels can be set to match to a 100:1 or 1000:1

interposing ZSCS using the mGARD-SYM interface.

The mGARD-SYM also provides an isolated connection to an external modbus RTU network. All 50 devices can be

monitored remotely using a single configurable modbus address. Built-in electrical isolation protects the modbus

network from hazardous voltages or transients. The display is compatible with several modbus speeds; 1200, 2400,

4800, 9600, 19200 and 38400 baud. Stop bits are selectable (1 or 2). Data available through modbus includes relay

status and fault levels as well as remote reset.

For more information on the mGARD-SYM display refer to the mGARD-SYM manual (C-416EM).

Figure 3.0 mGARD-SYM Remote Indicator

3.4 RESET

The mGARD-100 has a built in test/reset pushbutton button located on the faceplate. After a trip, the relay remains

in the tripped state until the ground fault has been cleared and the reset button has been pressed, or the control

voltage is removed from terminals L- & N+.

It is NOT necessary to press the remote test/reset button after the ground fault has been cleared when the

mGARD-100 is set in the pulsed trip auto reset mode. In this mode the relay will reset automatically in 3 seconds.

For remote reset capability, the relay must be connected to an mGARD-SYM remote indicator.

3.5 GROUND FAULT TEST

Double clicking the pushbutton located on the relay faceplate invokes a relay test. A simulated current which

exceeds the trip current set on the trip level DIP switches replaces the measured current. Once the trip delay time

set on the trip delay DIP switch has elapsed, the relay should trip and the green LED will blink at a fast rate. This

procedure tests the functionality of the unit.

After the trip, if the relay operating mode is manual reset, the output relay will remain tripped and the green LED

will blink fast until the reset button is pressed. If the relay operating mode is pulsed trip auto reset, the output relay

will reset and the green LED will revert to a slow ash 3 seconds after the test button was pushed or the test was

remotely invoked.

4. INSTALLATION INSTRUCTIONS

Hazard of Electrical Shock, Burn or Explosion

All installation, servicing and testing referred to in this manual must be

performed by qualified personnel. All power should be disconnected

prior to removing covers or enclosures and where live conductors

may otherwise be exposed.

Failure to observe these precautions may result in death or severe

personal injury and damage to equipment. Before placing an

intentional ground fault on the power system, check that a fault does

not already exist. Any test ground fault equipment must be rated for

full system voltage and be fused for protection.

DANGER

The internal electronics have been encapsulated in epoxy to improve the performance in high vibration

environments. Try to keep the exposure to mechanical shock and vibration to a minimum and place the mGARD-100

in a clean dry enclosure. Locate the relay close to the isolating device (circuit breaker or contactor) that is protecting

the circuit being monitored.

When using an interposing current sensor, keep the distance between the relay and the sensor as short as possible.

Use twisted cable and increase the gauge of the conductor as per the table below:

Table 4.0 ZSCS secondary wire run-length

Up to 300 Ft. / 91m. 16

301ft / 92m to 450ft / 137m 14

MAXIMUM CABLE RUN IN FEET/METERS MINIMUM WIRE GAUGE

Provide maximum clearance between the mGARD-100 (and the interposing ZSCS if required) and any strong

magnetic flux producing devices such as power transformers, autotransformers, control transformers, reactors, and

high power conductors and bus work.

4.1 MOUNTING

Refer to Figure 8.0 for mounting dimensions of the mGARD-100 relay. The mGARD-100 is designed to be mounted

with either mounting screws or on a 35 mm DIN rail.

Two #8-32 x 3/4” (M4 x 20) mounting screws are required for screw mounting.

For DIN rail mounting the rail should be bolted to a flat surface. Install the DIN rail horizontally. Allow at least ¾” (20

mm) of rail to extend beyond each end of the relay. Secure the relay to the DIN rail ensuring the release latch at the

bottom of the relay engages the rail. If the relay is to be mounted in any other position take appropriate steps to

prevent the relay from disengaging from the DIN rail.

4.2 BUILT-IN CURRENT TRANSFORMER

The mGARD-100 has a built-in current sensor (ZSCS) with 2.0” (50.8 mm) opening. The maximum continuous

primary phase current is 250 Amps. Refer to Table 4.1 below to determine the cable sizes that will fit through the

internal ZSCS.

WIRE SIZE 14 12 10 8 6 4 2

Diameter (inches) 0.126 0.142 0.179 0.241 0.31 0.358 0.418

of Cable (mm) 3.2 3.6 4.6 6.1 7.9 9.1 10.6

Table 4.1 Number of Conductors through the window of the mGard-100

3 Cables in.

(form factor 2.16) mm

0.27 0.3 0.39 0.52 0.67 0.77 0.95

6.9 7.8 10 13 17 20 23

4 Cables in.

(form factor 2.42) mm

0.3 0.34 0.43 0.59 0.75 0.87 1.02

7.74 8.7 11 15 19 22 26

6/7 Cables in.

(form factor 3.0) mm

0.37 0.43 0.54 0.73 0.93 1.07 1.26

9.6 10.8 14 18 24 27 32

9/10 Cablse in.

(form factor 3.85) mm

0.49 0.55 0.69 0.93 1.19 1.38 1.62

12.3 13.9 18 24 30 35 41

12 Cables in.

(form factor 4.15) mm

0.52 0.59 0.75 1 1.29 1.47 1.74

13.3 14.9 19 25 33 38 44

Sensor Type Inside

Diameter in mm

mGARD-100 T3A T6A

2.0 2.75 5.75

50 70 146

NO. OF CABLES IN FEEDER

Figure 4.0 illustrates a wiring arrangement for detecting ground faults on a solidly grounded system. Pass the

neutral and phase conductors through the ZSCS window. Note that the relay is located downstream of the neutral

ground point.

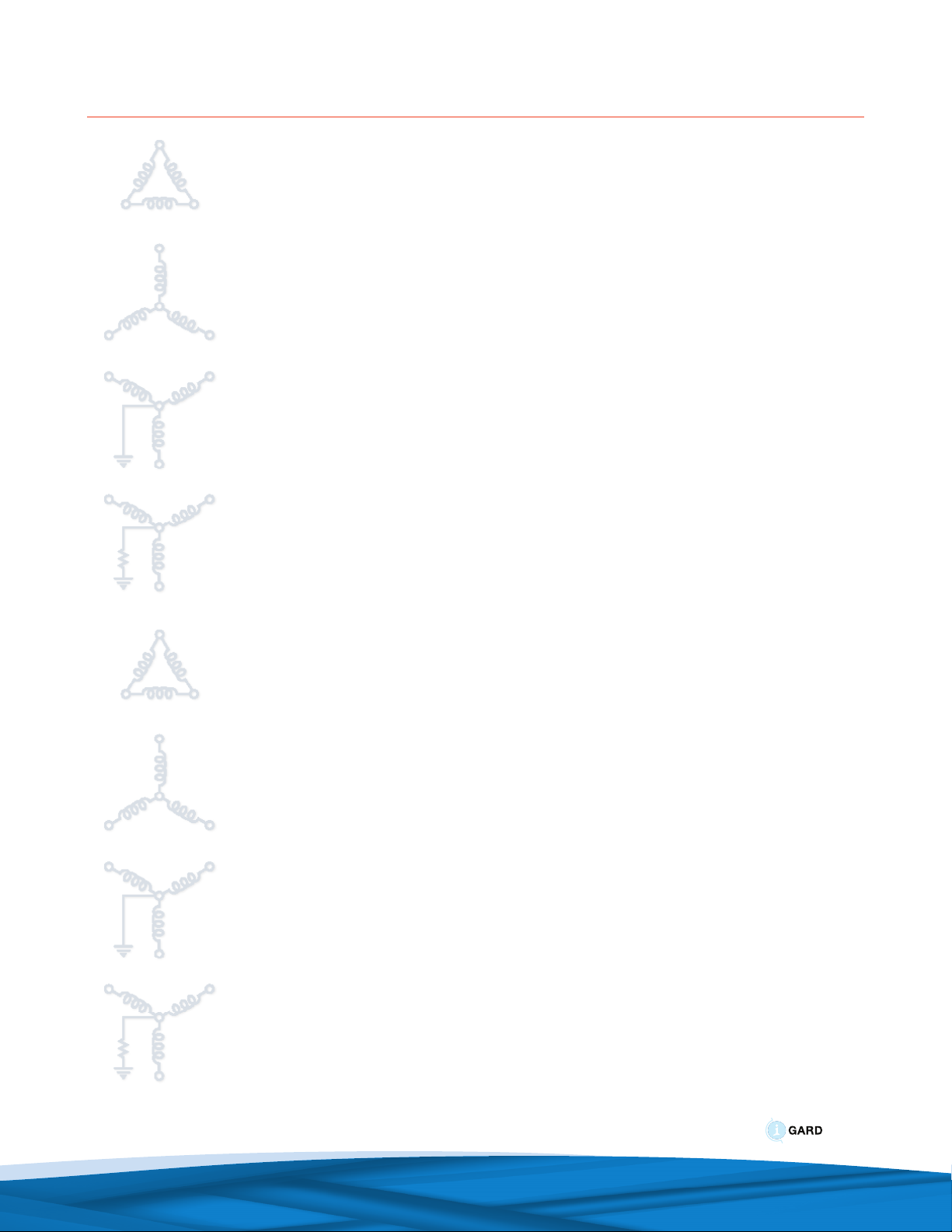

Figure 3.0 mGARD-SYM Remote Indicator

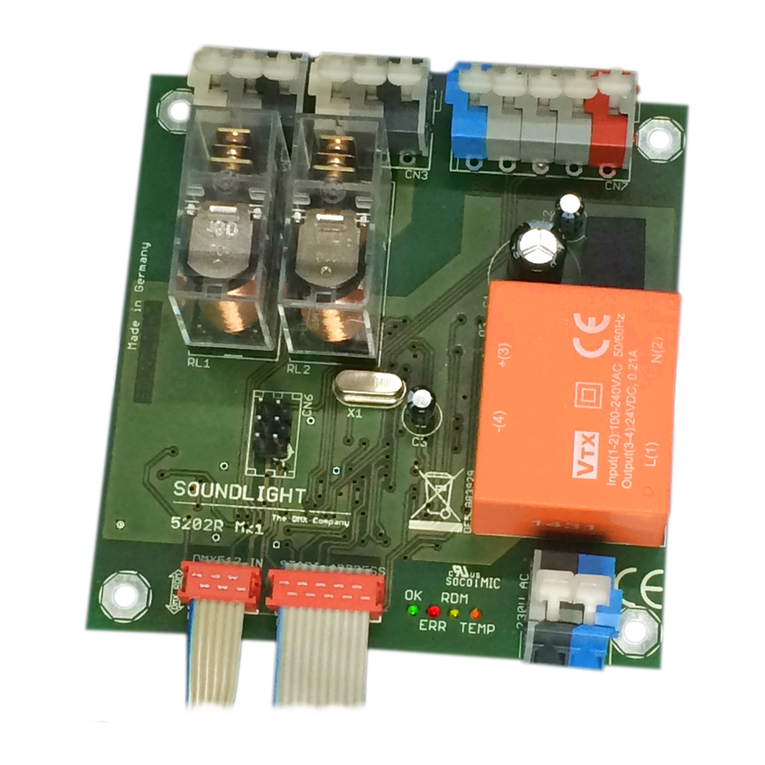

4.3 INTERPOSING CURRENT SENSORS

Refer to the glossary of terms to determine if an interposing current sensor is required for the application.

The mGARD-100 will work with I-Gard TxA and Rx-yA type zero sequence current sensors. Contact I-Gard for

the catalogue number of the zero sequence current sensor with the correct opening diameter required for the

application in case it is not shown on the table below or refer to the manual C-700 available at www.i-gard.com.

Refer to Figure 4.1, pass the phase and neutral conductors through the window of the interposing zero sequence

current sensor. Note that the relay is located downstream from the neutral ground point.

Position the cable in the centre of the zero sequence current sensor window opening. Keep cables and bus-work

clear of the split on split core zero sequence current sensors (T3A-S and T6A-S).

The two secondary terminals of the external zscs are to be routed through the window of the mGARD-100. If using

an mGARD-SYM, use the display to select the interposing I-Gard sensor that you are using to properly display

current levels.

Figure 4.1: mGARD-100 wired for external current sensor, failsafe operating mode, auto-reset with mGARD-SYM

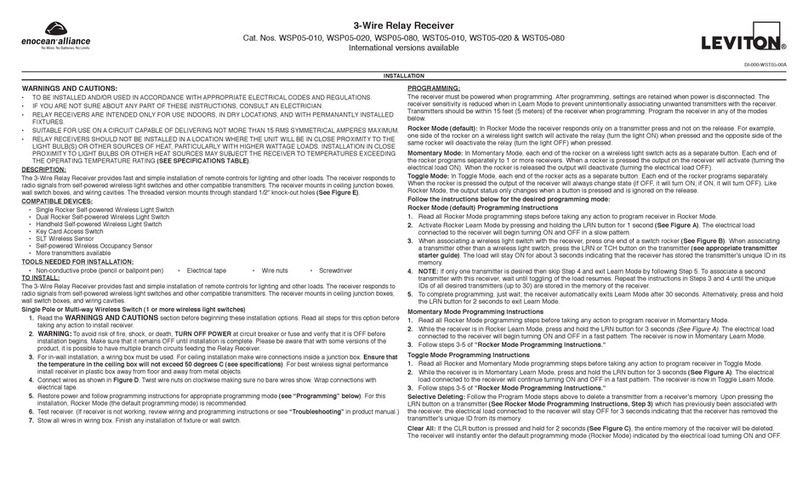

Figure 4.2: mGARD-100 relay monitoring a resistance grounded system and operating in failsafe mode.

Figure 4.2 shows an mGARD-100 relay operating in non-failsafe mode. The relay is monitoring the neutral conductor

in a resistance grounded system.

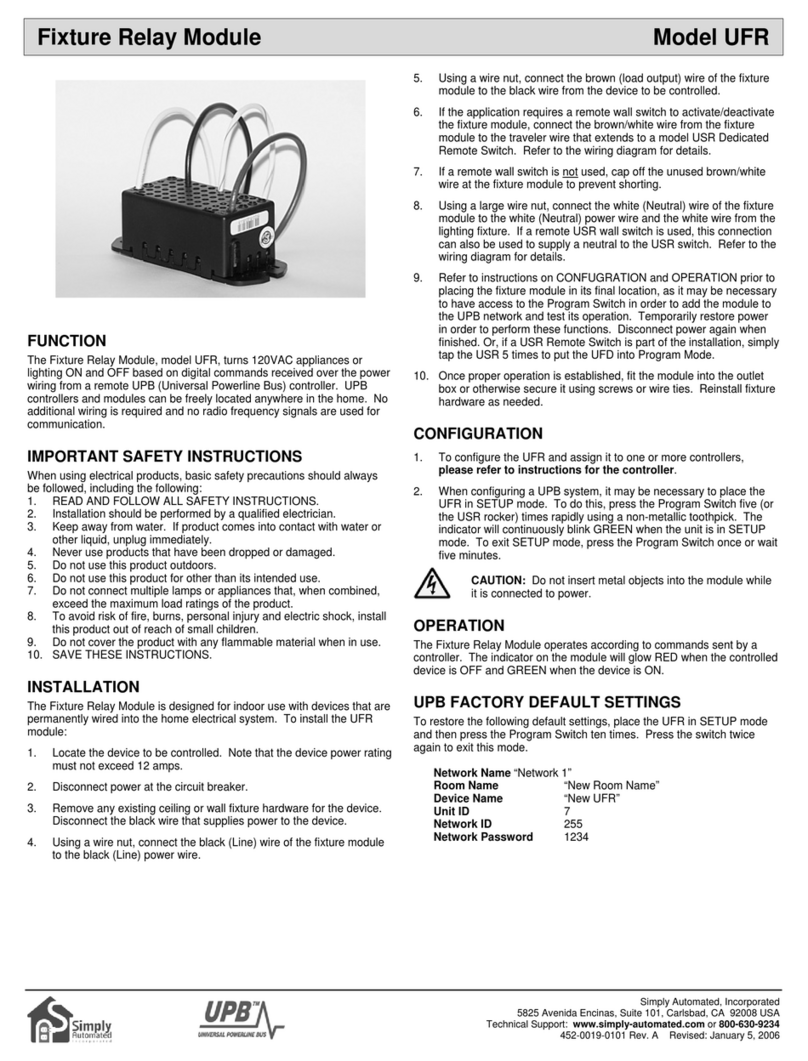

Figure 4.3 shows a system with several mGARD-100 relays monitoring branch circuits.

Figure 4.3: mGARD-100 relays used to monitor branch circuits, with mGARD-SYM remote indicator.

4.4 CONNECTIONS

All connections to the mGARD-100 are by means of screw clamp terminals rated 10 Amps, 300V. Terminals will

accept any wire gauges from #26 to #12 AWG solid or stranded conductors. The terminals are pull-apart style to

simplify wiring.

Connect AC or DC control power to terminals N- and L+.

In order to meet the Electromagnetic Compatibility (EMC) requirements a chassis bond is required between

terminal 7 and the nearest ground point. This distance should be kept to a minimum. If the mGARD-100 is

mounted on 35mm DIN rail, a DIN rail mounted ground terminal block can be installed beside the relay to act as

the chassis ground point.

mGARD-100 30mA-12A 20ms to 10s 2” window

CATALOGUE NUMBER LEVEL DELAY NOTES

mGARD-100 relay can be ordered with several low voltage DC power supplies as listed below in Table 5.1.

Table 5.1 mGARD-100 DC control voltage options

12V (9-18 VDC) /12DCV mGARD-100 /12DCV

24V (18-36 VDC) /24DCV mGARD-100 /24DCV

DC VOLTAGE RANGE CATALOGUE NUMBER SUFFIX EXAMPLE

6. SERVICE

For assistance in installation, set-up or testing please contact your nearest I-Gard representative, a list of

representatives is available at www.i-gard.com.

There are no recommended, user-serviceable parts in the mGARD-100. All other service should be referred

to qualified factory representatives, other than direct replacement of entire modules to I-Gard. Please visit the

I-Gard website for information regarding field service representatives in your area.

Note: Please ensure that proper authorization is obtained from I-Gard before returning any material.

5. CATALOGUE NUMBERS

All mGARD-10 relays can be ordered with several low voltage DC power supplies as listed below in Table 5.1.

control voltage, for use on 660V maximum, 50/60Hz power system.

Table 5.0 mGARD-100 relay catalogue number

7. TECHNICAL SPECIFICATIONS

Control Power:

3VA AC or 3W DC

40-240V AC/DC ±10% (36-264V AC/DC)

DC Control Power:

5V DC: 4.5-9 VDC, 1.5W

12V DC: 9-18 VDC, 1.5W

24V DC: 18-36 VDC, 1.5W

48V DC: 36-76 VDC, 1.5W

Temperature Range (Celsius):

Operating Temperature: -40OC to +65OC

Storage Temperature: -40OC to +85OC

Dielectric:

Relay contacts to chassis:

1480V rms. for 1 minute

Control terminals to chassi:

1480V rms. for 1 minute

Ground Fault:

Pickup Settings:

30mA, 40mA, 60mA, 90mA,

150mA, 250mA, 400mA, 600mA,

900mA, 1.5A, 2.5A, 4A, 6A, 9A,

10A, 12A

Pickup Tolerance: –15%, +0%

Delay Settings:

20ms, 50ms, 100ms, 200ms, 0.5s,

1s, 2s, 5s

Delay Tolerance: ±2.5%

Thermal Withstand:

Internal ZSCS:

10000 Amps for 1 seconds

Output Contacts:

Main Trip Relay:

Type: Form Z (N.O. and N.C. pair)

Rating: 10A @ 250V AC, resistive

10A @ 30V DC, resistive

Terminal Contact Material:

Clamping screw: nickel-plated brass

Plug contacts: tin-plated bronze

Physical:

Weight: 0.40 kg ( 0.88 lbs)

Dimension: See Figs. 8.0

Mounting:

Din Rail: 35mm

Two Screw: #8 x 3/4” (M4 x 20 mm)

Standards: CSA

Notes:

The mGARD-100 contains:

• An isolated power supply.

• A single Dual Pole Dual Throw (DPDT, 2 Form

C) relay for true failsafe operation.

30mA 25-30ms 20-25

40mA 25-30ms 20-25

60mA 25-30ms 20-25

90mA 25-30ms 20-25

150mA 25-30ms 20-25

250mA 25-30ms 20-25

400mA 25-30ms 20-25

600mA 30-35ms 25-30

900mA 25-30ms 20-25

1.5A 25-30ms 20-25

2.5A 25-30ms 20-25

4A 25-30ms 20-25

6A 30-35ms 20-25

9A 30-35ms 25-30

10A 25-35ms 25-30

12A 25-35ms 30-25

CURRENT

SETTING

DELAY (MS) WHEN CURRENT

EXCEEDS TRIP LEVEL BY FACTOR

Table 7.0 mGARD-100 timing with delay set to 20ms

X2 X4

I-GARD RESERVES THE RIGHT TO CHANGE SPECIFICATIONS OF ITS PRODUCTS WITHOUT NOTICE.

8. DIMENSIONAL DRAWINGS

Figure 8.0 mGARD-100 dimensions in millimetres (inches)

NOTES

Table of contents

Other I-Gard Relay manuals