7

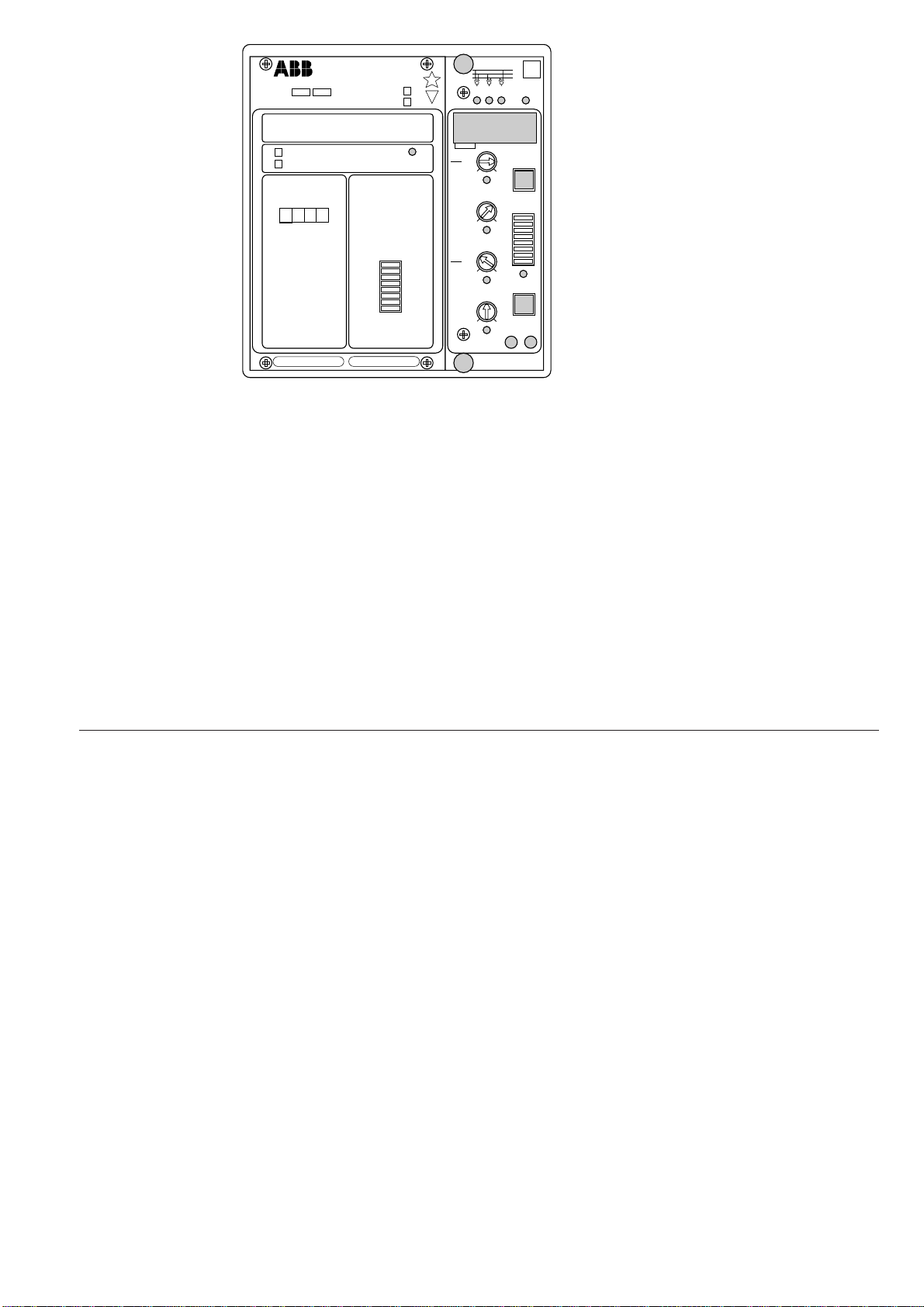

2. The yellow LED indicators (U12, U23 and

U31) on the upper black part of the front plate

indicate, when lit, that the corresponding

voltage value is currently being displayed.

3. The red IRF indicator of the self-supervision

system indicates, when lit, that a permanent

internal relay fault has been detected. The

fault code appearing on the display once a

fault has been detected should be recorded

and notified when service is ordered.

4. The green Uaux LED on the front panel is lit

whenthepower supplymoduleoperates prop-

erly.

5. The LED indicator below a particular setting

knob indicates, when lit, that the setting

value of the knob is currently being dis-

played.

6. The LED of the SG1 switchgroup indicates,

when lit, that the checksum of the switch-

group is currently being displayed.

The start and operation indicators, the function

of the SG2 software switchgroup and the func-

tions of the LED indicators during setting are

described more detailed in the user's manual

"Combined overvoltage and undervoltage relay

module SPCU 3C14".

Start and

operation

indicators 12

IRF

>

U

23

U

31

U

U

1315

[ ]

s

k>

t

0.5

0.05 1.0

0.8

0.4

5.0

1.0 12

0.8

1.2

1.6

STEP

RESET

SG1

01

1

2

3

4

5

6

7

8

<

U

n

U

>

U

<

t

[ ]

s

>

U

<

U

SPCU 3C14

n

U

<

U

1.2

STEP

RS 422 Ser.No.

SPAU 130 C

2

5

1308

f

n= 50Hz

60Hz

1

2

3

4

5

6

7

8/

>

tt

n

)(

>

n

)(

<

<

/

tt

%

[]

%

[]

U

aux

80...265V ~

–

18...80V –

SPCU 3C14

REGISTERS

0000

1

2

3

4

5

6

7

8

01

SGR

n

/

UU

U

U

n

U

=100V 110V

>

n

/

UU

max

n

/

UU

<

n

/

UU

min

1. The relay module is provided with two opera-

tion indicator located in the right bottom

corner of the front plate of the relay module.

One indicates operation of the overvoltage

stage and the other operation of the under-

voltage stage. Yellow light indicates that the

concerned stage has started and red light that

the stage has operated (tripped).

With the SG2 software switchgroup the start

and trip indicators can be given a latching

function, which means that the LEDs remain

lit, although the signal that caused operation

returns to normal. The indicators are reset

with the RESET push-button. An unreset

indicator does not affect the operation of the

relay.

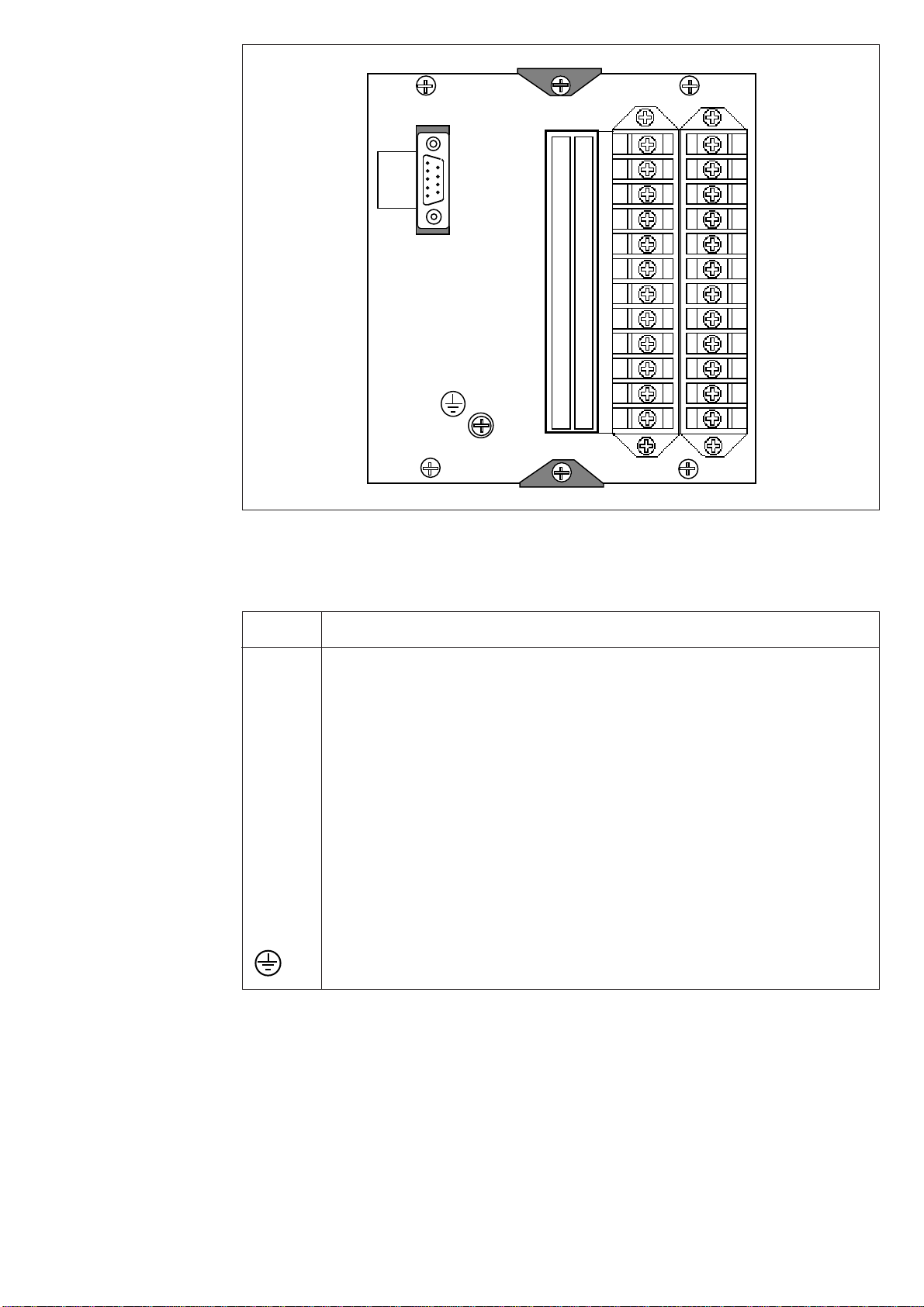

Combined power

supply and I/O

module

The combined power supply and I/O module

(U2) is located behind the system front panel of

the protection relay and can be withdrawn after

removal of the system front panel. The power

supply and I/O module incorporates a power

unit, four output relays, the control circuits of

the output relays and the electronic circuitry of

the external control input.

The power unit is transformer connected, that

is, the primary side and the secondary circuits

are galvanically isolated. The primary side is

protected by a slow 1 A fuse F1, placed on the

PC board of the module. When the power

source operates properly, the green Uaux LED

on the front panel is lit.

The power supply and I/O module is available

in two versions which have different input volt-

age ranges:

- type SPTU 240S1 Uaux = 80...265 V ac/dc

- type SPTU 48S1 Uaux = 18...80 V dc

The voltage range of the power supply and I/O

module inserted in the relay is marked on the

system front panel of the relay.