I-Gard SIGMA 3 User manual

C-EG44EM, February 2021

SIGMA 3

GROUND FAULT RELAY

2

I-Gard’s commitment to electrical safety provides both industrial and commercial

customers with the products needed to protect their electrical equipment and the

people that operate them.

As the only electrical-safety focused company whose product portfolio includes

neutral grounding resistors, high-resistance grounding systems and optical arc

mitigation, we take pride in our technologies that reduce the frequency and

impact of electrical hazards, such as arc flash and ground faults.

For those customers who have purchased from us over the last 30 years, you

know us for the quality and robustness of our products, our focus on customer

service and technical leadership. We build on this foundation by investing

in developing new products in electrical safety education - including EFC

scholarship program - by actively participating in the IEEE community programs

on technical and electrical safety standard, and working with local universities

at discovering new technologies. We remain unrelenting in our goal of improving

electrical safety in the workplace.

Our commitment to excellence is validated by long-standing relationships with

industry leaders in fields as diverse as petroleum and gas, hospitals, automotive,

data centers, food processing, aerospace, water and waste water plants, and

telecommunications. We provide our customers with the product and application

support required to ensure that their electrical distribution system is safe and reliable.

ABOUT IGARD

1

SUBJECT

1. Introduction .................................................................................................................................2

2. Description ..................................................................................................................................2

3. Operation ....................................................................................................................................2

4. Trip Relay and Auxiliary Fault Relays .......................................................................................6

5. LED Indicators and Diagnostics ................................................................................................6

6. Settings .......................................................................................................................................8

7. Use with Sigma3-TDM Touchscreen Display Module ...........................................................14

8. MODBUS Communication ........................................................................................................18

9. Installation .................................................................................................................................22

10. Commissioning ..........................................................................................................................25

11. Technical Specifications ............................................................................................................32

12. Catalogue Numbers ...................................................................................................................33

Appendix A: Excerpt from CAN / CSA M421-00: Use of Electricity in Mines .............................33

TABLES

Table 6.1: Trip Relay Operating Mode Setting Dip switch #1 (left hand array)

Table 6.2 Trip Memory Selection Dip switch #2 (left hand array)

Table 6.3 Ground Fault Trip Time Delay Settings Dip switches #3 - #4 - #5 - #6 - #7 (left hand

array)

Table 6.4 Ground Fault Trip Current Level Settings Dip switches #8 - #9 - #10 (left hand array)

Table 6.5 System Frequency Selection Dip Switch #11 (right hand array)

Table 6.6 NGR Let-through Current Settings Dip Switches #12 - #13 - #14 - #15 - #16 (Right

Hand Array )

Table 8.1: MODBUS ID Address Map

Table 8.2: MODBUS RTU Standard 8 Byte Holding Register Read Function (03)

Table 8.3: Returned Information Structure for Holding Register Request

Table 8.4: Sigma Relay Register Definitions

Table 8.5: Relay Status Registers

Table 8.6: MODBUS Register Format Conventions

Table 10.1 NGR Test Values

FIGURES

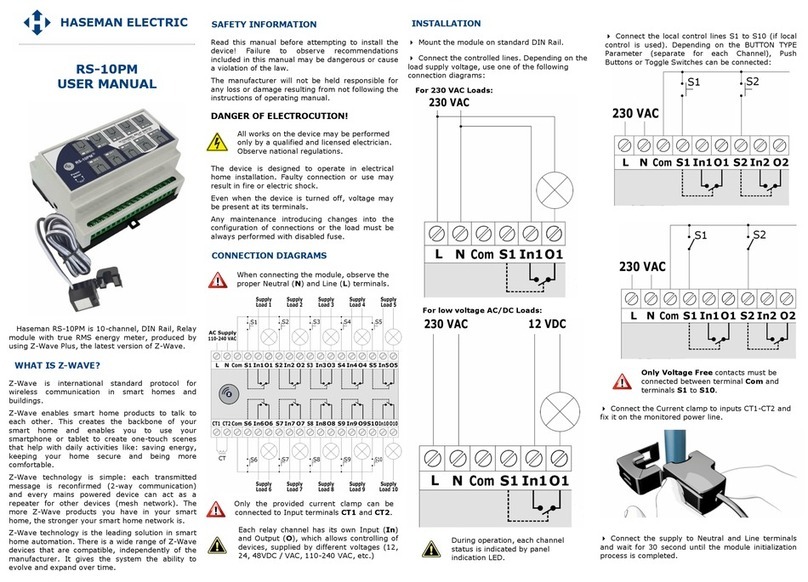

Figure 3.1: Sigma 3 Typical System Diagram (HRG System)

Figure 3.2: Sigma 3 Typical System Diagram (LRG System)

Figure 3.3: The Creation of a Pulse Signature by Cycling the Let-Through Current Under Various

Arrangements

Figure 6.1: Sigma 3 Dip Switch Array

Figure 7.1: Sigma 3 to Sigma3-TDM Connection Diagram

Figure 7.2: Home Screen

Figure 7.3: Status Screen

Figure 7.4: Event Log

Figure 7.5: Settings Page

Figure 7.6: Sigma and Alarm Settings Page

Figure 7.7: Pulse Contactor Settings Page

Figure 7.8: Communications Settings Page

Figure 8.1(a): Preferred 4-wire MODBUS Communication Connection

Figure 8.1(b): Alternate 2-wire MODBUS Communication Connection

Figure 9.1: Sigma 3 Terminal Connections

Figure 10.1: Potentiometer to be used to Adjust HF1 Current

Figure 10.2(a): Setup for Offline Calibration Showing the Ammeter Connected

Figure 10.2(b): Example of DC Ammeter used in Calibration Procedure

Figure 10.3: Partial Short NGR when Performing Offline Calibration

Figure 10.4: Sigma3-TDM to Sigma3 Connection

Figure 10.5: Sigma3 Settings Page

Figure 10.6: Sigma3 Calibration Page

Figure 11.1: Dimensional Drawings

TABLE OF CONTENTS

2

1. INTRODUCTION

The I-Gard Sigma 3 monitor relay is a combination ground fault relay and Neutral Grounding Resistor (NGR)

monitoring relay. The Sigma 3 monitor relay protects against ground faults and abnormal resistance values of the

NGR.

The Sigma 3 monitor relay is specically designed for a variety of system voltages and an NGR limiting the

maximum NGR current to the relay’s set let-through current.

The Sigma 3 monitor relay is designed to operate with a TxA or Rx-yA zero sequence current sensor, an NGRS#

sensing resistor with NGRX lter, and an NGR sized to limit ground fault current.

The let-through current measured by the zero sequence current sensor will be the vector sum of any leakage

currents or charging currents normally in the system and any ground fault currents that may be present.

2. DESCRIPTION

The Sigma 3 monitor relay measures the current through the NGR, the transformer neutral-to-ground voltage, and

the NGR resistance. The relay compares the measured values with the eld settings of the relay and provides relay

outputs and LED indications when an abnormal condition is detected.

Ground fault current is measured using the zero sequence current sensor. The ground fault trip level is DIP switch

selectable as a percentage of the NGR let-through current setting at 5%, 10%, 15%, 20%, 25%, 30%, 40%, and

50%. Trip time is DIP switch selectable from 60 milliseconds to 3.15 seconds.

Neutral-to-ground voltage is measured by means of the NGRS-. The NGRS- sensing resistor is used by the Sigma

3 monitor relay in combination with the zero sequence current sensor as part of a comparator to monitor the NGR

resistance. This NGR resistance monitoring complies with the requirements of CSA C22.1 section 10-302.

The Sigma 3 monitor relay provides a current source output for connection to a 1mA full scale ammeter. The output

signal is proportional to the measured current and is expressed as a percentage of the NGR let-through current

setting.

A watchdog failsafe normally open contact is also provided.

Pulsing signal terminals are provided to facilitate pulsing of the NGR as a ground fault locating technique where the

NGR is outtted with a solid state relay pulsing contactor.

The Sigma 3 can be used with the Sigma3-TDM touchscreen display module to provide an advanced HMI.

3. OPERATION

3.1 System Components

The Sigma 3 is used with voltage and current sensors to monitor the system. The NGRS-## sensing resistor is

used to sense the voltage over the NGR. The zero sequence current sensor, which is used to sense the current

through the NGR, is an i-Gard type T2A, T3A, TxA or any Rx-yA zero sequence current sensor. In addition, the

Sigma 3 operates in injection mode when the current through the NGR is low, whereby a high frequency signal

is injected into the system to measure the zero sequence impedance. A lter is used in conjunction with the high

frequency injection signal called the NGRX. Combination NGRS / NGRX are also available, called NGRXS-##.

3

For High Resistance Grounded Systems (HRG) a single high frequency injection channel (HF1) is employed. See

Figure 3.1 below for the typical system with the Sigma 3 connections. For Low Resistance Grounded Systems

(LRG) two high frequency injection channels (HF1 and HF2) are employed. See Figure 3.2 below for the typical

system with the Sigma 3 connections.

Figure 3.1: Sigma 3 Typical System Diagram (HRG System)

4

DANGER

Figure 3.2: Sigma 3 Typical System Diagram (LRG System)

3.2 Ground Fault Detection

The Sigma 3 monitor detects ground faults by measuring the current through the NGR using the zero sequence

current sensor (TxA or Rx-yA sensors). When the measured value exceeds the set-point the GND FLT LED

illuminates, the GND FLT form-C contact energizes, and the trip relays energize.

The Sigma 3’s NGR let-through current setting is set by DIP switch to match the rating of the NGR. The trip level

is DIP switch selectable as a percentage of the NGR let-through current setting and can be set as: 5%, 10%, 15%,

20%, 25%, 30%, 40%, and 50%.

The ground fault trip delay setting denes the length of time that a ground fault must persist before the fault is

qualied as such. This setting is DIP switch selectable from its minimum setting of 60 milliseconds to 3.15 seconds.

5

3.3 NGR Monitoring

The Sigma 3 monitor relay also monitors the health of the NGR to ensure that it does not become open or short

circuit. If the Sigma 3 determines that the NGR is not healthy the NGR FLT LED illuminates, the NGR FLT form-C

contact energizes, and the trip relays energize.

The Sigma 3 monitor relay monitors the NGR using one of two methods: measurement mode and injection mode.

If the leakage current through the NGR is over 5% of the rated let-through current, the Sigma 3 operates in

measurement mode. In measurement mode, the leakage current through the NGR is measured by the ZSCS and

the voltage across the NGR is measured by the NGRS. The Sigma 3 uses these values to calculate the apparent

resistance of the NGR. If this calculated value is determined to be over 150% of the nominal value or less than 66%

of the nominal value, the Sigma 3 annunciates an NGR fault.

If the leakage current through the NGR is below 5% of the rated let-through current, the Sigma 3 operates in

injection mode. In injection mode, a high frequency signal is injected into the system through a band-pass

lter (NGRX). The Sigma 3 uses the current and voltage of the high frequency signal to calculate the apparent

resistance of the NGR. If this calculated value is determined to be over 150% of the nominal value or less than 66%

of the nominal value, the Sigma 3 annunciates an NGR fault.

3.4 Pulsing

Pulsing is a technique that is employed in high resistance grounded systems to locate a ground fault. The NGR

is divided into a non-pulsing section and a pulsing section that includes a contactor. The pulsing section can be

inserted into the system by the operation the contactor. This cycles the let-through current of the NGR between

different values (usually from 50% to 100% of the rated let-through current) and this signature can be used to trace

the location of the ground fault. Various pulse arrangements are shown in Figure 3.3 below.

Pulse signals are available from the Sigma 3 that can be used to create the signature by driving an NO solid state

relay that is used as the pulsing contactor. These are available at terminals 19, 20, and 21. If using pulse down

signals use terminals 19 and 21. If using pulse up signals use terminals 20 and 21. Terminals 19-21 are normally

energized with +12VDC and terminals 20-21 are normally de-energized. When pulsing is enabled by closing

terminals 25-26 or by enabling at the Sigma3-TDM touchscreen HMI, the pulse signals cycle at a frequency of 1Hz.

The cycle frequency can be changed using the Sigma3-TDM touchscreen HMI.

Figure 3.3: The creation of a pulse signature by cycling the let-through current under various arrangements

6

4. TRIP RELAY AND AUXILIARY FAULT RELAYS

The Sigma 3 has four output relays:

- A TRIP relay

- An NGR FAULT auxiliary relay

- A GROUND FAULT auxiliary relay

- A WATCHDOG auxiliary relay

All relays are electrically held, i.e. when control power is off the relays are always in the de-energized state. The de-

energized states are shown on the front of the Sigma 3. Note that this is irrespective of the trip relay operating mode.

All relays can be in one of two states: idle or tripped. For the trip relay, its status (energized or de-energized) when in

each of these states depends on its operating mode, which is set by DIP switch 1.

4.1 Trip Relay (15-16, 17-18)

A trip relay consisting of an NO and NC pair is provided. Terminal 15-16 is normally closed and terminal 17-18 is nor-

mally open. This relay energizes on occurrence of a ground fault or NGR fault. The trip relay can be programmed for

shunt trip or failsafe operation.

When the Sigma 3 is operating in shunt trip mode, when there is no fault condition present the trip relay remains idle

(de-energized). If a fault condition is detected and qualied, the trip relays becomes tripped (energized).

When the Sigma 3 is operating in failsafe mode, when there is no fault condition present the trip relay is normally idle

or energized. The trip relay is tripped of de-energized if a fault condition is detected on the system. The trip relay is

also de-energized when control power is off.

4.2 NGR Fault (AUXILIARY RELAY)

A Form-C auxiliary contact for NGR faults is provided. This is located at terminals 39, 40, and 41. The NGR FAULT

auxiliary relay operates exclusively in shunt trip mode regardless of the setting of DIP switch.

4.3 Ground Fault (AUXILIARY RELAY)

A Form-C auxiliary contact for ground faults is provided. This is located at terminals 42, 43, and 44. The GROUND

FAULT auxiliary relay operates exclusively in shunt trip mode regardless of the setting of DIP switch.

4.4 Watchdog (51-52)

Terminals 51-52 is a system normal watchdog. When the Sigma 3 is de-energized it is open. When the Sigma 3 is

energized but not in alarm it is closed. If the Sigma 3 goes into alarm mode, the watchdog changes state and opens

back.

5. LED INDICATORS AND DIAGNOSTICS

The Sigma 3 has 4 indication LEDs located on its front panel: the Green PWR (Power) LED; the Red GND (Ground)

FAULT LED; the Red NGR FAULT LED; and the ZONE GR. (Zone Grading) LED.

5.1 Start-up and Reset Indications

The Sigma 3 has a start-up sequence where the Red GND FAULT, NGR FAULT and ZONE GR. LEDs ash twice

before being turned OFF. The Green PWR LED may also ash before it is turned ON.

7

During a manual reset the Red GND FAULT, NGR FAULT and ZONE GR. LEDs turn ON for two seconds as indication that the

reset sequence is taking place. During this time the Green PWR LED will intermittently ash. After this sequence the LEDs

give the start-up sequence described above.

After the Sigma 3 has gone through the start-up sequence and is operating normally the Green PWR LED will turn ON and

the Red GND FAULT, NGR FAULT and ZONE GR. LEDs will turn off.

5.2 Power On LED (Green)

The Green PWR LED will turn ON when control power is applied to the Sigma 3 and the relay is operating normally.

The Green PWR LED will intermittently ash if control power is applied to the Sigma 3 but the relay is not operating correctly

due to a malfunction in the microprocessor circuit. Control power must be cycled in order to reset the Sigma 3.

The Greed PWR LED will intermittently ash during a manual reset or a power-up reset.

5.3 GND Fault LED (Red)

The Red GND FAULT LED will turn OFF when the Sigma 3 is operating normally and no ground fault has been detected or

qualied.

The Red GND FAULT LED will turn ON when the Sigma 3 has detected and qualied a ground fault. The Red GND FAULT

LED will remain ON until the Sigma 3 is manually reset even if the ground fault condition has been rectied.

The Red GND FAULT LED will intermittently ash when the Sigma 3 is powered up after having been powered down while

indicating a ground fault. The Sigma 3 must be manually reset to clear this condition.

The Red GND FAULT LED will turn on during manual reset as described above.

5.4 NGR Fault LED (Red)

The Red NGR FAULT LED will turn OFF when the Sigma 3 is operating normally and no NGR Fault has been detected and

qualied.

The Red NGR FAULT LED will turn ON when the Sigma 3 has detected and qualied an NGR Fault. The RED NGR FAULT

LED will remain ON until the Sigma 3 is manually reset even if the NGR fault condition has been corrected.

The Red NGR FAULT LED will intermittently ash when the relay is powered up after having been powered down while indi-

cating an NGR Fault. The Sigma 3 must be manually reset to clear this condition.

The Red NGR FAULT LED will turn ON during a manual reset as described above.

5.5 Func. (Red)

The FUNCTION LED will turn ON when the ZONE I/L input circuit is active, i.e. Normally Open (NO) contacts connected to

these inputs are closed.

The FUNCTION LED will intermittently ash when the relay’s self-test circuit is enabled through the operation of the TEST

pushbutton on the front panel.

The FUNCTION LED will turn ON while the installer is adjusting the operational settings on the Sigma 3 by way of the DIP

switches. When the relay detects that the installer has stopped making adjustments to these settings the Red ZONE GR. LED

will turn OFF.

The FUNCTION LED will turn ON during a manual reset as described above.

8

6. SETTINGS

Settings are dened using selectable DIP switches. A diagram of the DIP switch array is shown in Figure 6.1 below.

Figure 6.1: Sigma 3 Dip Switch Array

6.1 Trip Relay Operating Modes

The trip relay operating settings can be set with DIP switch 1. The Sigma 3 can be set for a shunt trip operating mode

(not failsafe) or an undervoltage trip operating mode (failsafe) operation with the trip relay operating mode dip switch.

See Table 6.1 for conguration details.

6.1.1 Shunt Trip Mode

In the shunt trip mode (not failsafe), the trip relay remains de-energized (no trip) when control voltage is applied to the

Sigma monitor relay and the system is operating normally. The trip relay is energized (trip) when the measured values

of the ground fault current or NGR Resistance exceed the threshold settings for the time specied.

The trip relay will energize (trip) after a fault is qualied and will remain energized (tripped) until the Sigma monitor relay

is reset whether or not the fault that caused the trip remains present on the system. The trip relay will be de-energized

(no-trip) if the control voltage is removed.

When control voltage is applied the trip relay will at rst be de-energized (no-trip) and the Sigma monitor relay will start

operating normally. If the trip memory option is OFF the trip relay will remain de-energized (no-trip). However, if the trip

memory option is ON and a trip state is stored in the non-volatile memory, the trip relay will energize (trip) approximate-

ly 1 second after control voltage is applied and will remain energized (tripped), regardless of whether a fault is present

on the system.

The trip relay will de-energize (no-trip) if the Sigma monitor relay is reset through a local or remote reset. When reset,

the Sigma monitor relay will resume monitoring of the system and, if a fault remains on the system, will detect the fault

and will re-trip, energizing the trip relay.

6.1.2 Failsafe (Undervoltage Trip) Mode

When programmed for the FAILSAFE (UNDERVOLTAGE TRIP) MODE and the Sigma 3 is operating normally, the trip

relay energizes approximately 1 second after control voltage is applied. The trip relay de-energizes (trips) under any of

the following conditions:

- The measured values of the ground fault current or NGR resistance exceed the threshold settings for the

time specied

- The Sigma 3 is reset

- Control voltage is removed

9

The trip relay remains energized after a trip, providing control voltage is present, until the Sigma 3 is reset whether or

not the fault that caused the trip remains present on the system.

When control voltage is applied the trip relay will at rst be energized (no-trip) and the Sigma 3 will start operating

normally. If the trip memory option is OFF the trip relay will remain energized (no-trip). However, if the trip memory

option is ON and a trip state is stored in the non-volatile memory, the trip relay will de-energize (trip) approximately

1 second after control voltage is applied to the relay and will remain de-energized (tripped), regardless of whether a

fault is present on the system.

The trip relay will energize (no-trip) if the Sigma 3 is reset through a local or remote reset. When reset, the Sigma 3

will resume monitoring of the system and, if a fault remains on the system, will detect the fault and will re-trip, de-

energizing the trip relay.

6.2 Trip Memory Setting

The trip memory settings can be set with DIP switch 2. The Sigma 3 stores the states of the trip relay and auxiliary

fault relays in non-volatile memory and can, if programmed to do so by means of the TRIP MEMORY Setting, restore

the state of the trip relay when control power is applied.

The Sigma 3 can be set for trip memory ON (DIP switch #2 UP) or trip memory OFF (DIP switch #2 DOWN). See

Table 6.2 for conguration details.

When the trip memory option is OFF the trip relay and auxiliary fault relays are returned to their idle operating states

when control power is applied.

When the trip memory is ON the trip relay and auxiliary fault relays are restored to the state these relays had prior to

the loss of control power. If the Sigma 3 was indicating a fault condition when control power was lost, the states of the

trip relay and auxiliary fault relays will be maintained until the relay is manually reset.

The Sigma 3 retains the states of the trip relay and auxiliary fault relays stored in non-volatile memory indenitely.

6.3 Ground Fault Trip Time Delay

The ground fault time delay settings can be set with DIP switches 3-7. The Sigma 3 can be programmed for ground

fault trip delays ranging from 60 milliseconds to 3.15 seconds.

Refer to TABLE 6.3 GROUND FAULT TRIP TIME DELAY SETTINGS to determine the DIP switch settings for the ap-

plication.

6.4 Ground Fault Trip Current Level

The ground fault trip current level setting can be set with DIP switches 8-10. The Sigma 3 can be programmed for a

number of ground fault trip levels expressed as a percentage of the NGR let-through current setting. Eight ground

fault trip level settings are available and are: 5%; 10%; 15%; 20%; 25%; 30%; 40%; 50%.

I-Gard recommends that the ground fault trip level setting be set as low as possible to provide maximum operating

personnel and equipment protection without having the Sigma 3 report ground faults falsely.

Refer to TABLE 6.4 GROUND FAULT TRIP CURRENT LEVEL SETTINGS to determine the DIP switch settings for

the application.

Caution: CAN/CSA-M421-00 Use of Electricity in Mines Paragraph 3.5.5 states, in part, that “Where ground-fault

protection is used, the supply shall be … de-energized in less than 1s if ground-fault current exceeds 20% of the pro-

spective ground-fault current”. Therefore, I-Gard recommends that the ground fault trip level be set as low as possible

and not higher than 20% when complying with this CSA Mine Safety Standard.

10

6.5 System Frequency

The system frequency setting can be set with DIP switches 11. A system frequency of 50Hz or 60Hz can be chosen.

Refer to TABLE 6.5 SYSTEM FREQUENCY SETTINGS to determine the DIP switch settings for the application.

6.6 NGR Let-Through Current

The NGR let-through current setting can be set with DIP switches 12-16. The Sigma monitor relay has thirty two

settings for the NGR let-through current. Refer to TABLE 6.6 FOR DIP SWITCH SETTINGS for the NGR let-through

current.

The NGR let-through current settings in Table 9.6 show that the Sigma monitor relay can be congured for let-through

currents ranging from 5 Amperes through 400 Amperes using a standard I-Gard TxA ZSCS.

The NGR let-through current settings in Table 6.6 are intended to show that the Sigma monitor relay can be cong-

ured for let-through currents ranging from 1 Ampere through 4 Amperes using a standard I-Gard TxA ZSCS with the

conductor carrying the NGR current wrapped through the CT’s primary window 10 times to create a primary winding

of 10 turns.

The Sigma monitor relay can be congured for let-through currents over 400 Amperes using an I-Gard ZSCS sized for

the intended application.

Contact the factory if settings other than those are required in the intended application.

6.7 DIP Switch Congurations

Mode Dip Switch Setting

Failsafe (Undervoltage Trip)

Sigma Relay is Idle/Not-Tripped:

Trip Relay is energized

Aux Fault Relays are not energized

Sigma Relay is Tripped:

Trip Relay is energized

Aux Fault Relays are energized

UP

Non-Failsafe (Shunt Trip)

Sigma Relay is Idle/Not-Tripped

Trip Relay is not Energized

Aux Fault Relays are not energized

Sigma Relay is Tripped

Trip Relay is Energized

Aux Fault Relays are energized

DOWN

Table 6.1: Trip Relay Operating Mode Setting Dip Switch #1 (left hand array)

(U = Up, D = Down)

11

Trip Memory On/Off Dip Switch Setting

TRIP MEMORY ON

Control voltage off after trip:

When control voltage restored

Trip and Aux relays idle* then immediately

re-trip (within 2 seconds).

UP

TRIP MEMORY OFF

Control voltage off after trip:

When control voltage restored

Trip and Aux relays idle* but do not

immediately re-trip

Trip and Aux relays will re-trip if a fault is

detected after monitoring starts.

DOWN

Table 6.2: Trip Memory Selection Dip Switch #2 (Left hand array)

(U = Up, D = Down)

Ground Fault Trip Time

Delay (in milliseconds)

Dip Switch Settings

3 4 5 6 7

60 D D D D D

150 D D D D U

250 D D D U D

350 D D D U U

450 D D U D D

550 D D U D U

650 D D U U D

750 D D U U U

850 D U D D D

950 D U D D U

1050 D U D U D

1150 D U D U U

1250 D U U D D

1350 D U U D U

1450 D U U U D

1550 D U U U U

1650 U D D D D

12

1750 U D D D U

1850 U D D U D

1950 U D D U U

2050 U D U D D

2150 U D U D U

2250 U D U U D

2350 U D U U U

2450 U U D D D

2550 U U D D U

2650 U U D U D

2750 U U D U U

2850 U U U D D

2950 U U U D U

3050 U U U U D

3150 U U U U U

(U = Up, D = Down)

Table 6.3: Ground Fault Trip Time Delay Settings Dip Switches #3-#4-#5-#6-#7 (left hand array)

Ground Fault Trip Level (% of NGR

Let-Through Current)

Dip Switch Settings

8 9 10

5% D D D

10% D D U

15% D U D

20% D U U

25% U D D

30% U D U

40% U U D

50% U U U

(U = Up, D = Down)

Table 6.4: Ground Fault Trip Current Level Settings Dip Switches #8 - #9 - #10 (left hand array)

System Frequency 60/50 Hz Dip Switch Setting

System Frequency 50 Hz U

System Frequency 60 Hz D

Table 6.5: System Frequency Selection Dip Switch #11 (right hand array)

(U = Up, D = Down)

13

NGR Let-Through

Current (Amps)

Dip Switch Settings ZSCS Employed

12 13 14 15 16

1 D D D D U TxA or Rx-yA w/10 Turns

Through Primary

2 D D D U U TxA or Rx-yA w/10 Turns

Through Primary

3 D D U D U TxA or Rx-yA w/10 Turns

Through Primary

4 D D U U U TxA or Rx-yA w/10 Turns

Through Primary

5 D D D D D TxA or Rx-yA

10 D D D D U TxA or Rx-yA

15 D D D U D TxA or Rx-yA

20 D D D U U TxA or Rx-yA

25 D D U D D TxA or Rx-yA

30 D D U D U TxA or Rx-yA

35 D D U U D TxA or Rx-yA

40 D D U U U TxA or Rx-yA

45 D U D D D TxA or Rx-yA

50 D U D D U TxA or Rx-yA

55 D U D U D TxA or Rx-yA

60 D U D U U TxA or Rx-yA

65 D U U D D TxA or Rx-yA

70 D U U D U TxA or Rx-yA

75 D U U U D TxA or Rx-yA

80 D U U U U TxA or Rx-yA

90 U D D D U TxA or Rx-yA

95 U D D U D TxA or Rx-yA

100 U D D U U TxA or Rx-yA

125 U D U D D TxA or Rx-yA

150 U D U D U TxA or Rx-yA

175 U D U U D TxA or Rx-yA

14

200 U D U U U TxA or Rx-yA

225 U U D D D TxA or Rx-yA

250 U U D D U TxA or Rx-yA

275 U U D U D TxA or Rx-yA

300 U U D U U TxA or Rx-yA

325 U U U D D TxA or Rx-yA

350 U U U D U TxA or Rx-yA

375 U U U U D TxA or Rx-yA

400 U U U U U TxA or Rx-yA

500 D U D D U 10,000:1

600 D U D U U 10,000:1

800 D U U U U 10,000:1

1000 U D D U U 10,000:1

1250 U D U D D 10,000:1

1500 U D U D U 10,000:1

2000 U D U U U 10,000:1

2250 U U D D D 10,000:1

2500 U U D D U 10,000:1

(U = Up, D = Down)

Table 6.6: NGR Let-Through Current Settings Dip Switches #12-#13-#14-#15-#16 (Right Hand Array)

7. USE WITH TOUCHSCREEN DISPLAY MODULE

The Sigma 3 can be used with a touchscreen HMI called the Sigma3-TDM. The Sigma 3 is connected to the Sigma3-

TDM using its MODBUS communication. The connection of the Sigma 3 to the Sigma3-TDM is shown in Figure 7.1.

The Sigma3-TDM touchscreen HMI provides for: display of the status and readings of the Sigma 3; conguration and

operation of pulse contactor settings; viewing of logging and trending data; remote reset of the Sigma 3; as well as

providing TCP/IP communication.

When the Sigma 3 is connected to the Sigma3-TDM the home screen shown in Figure 7.2 below appears on the

Sigma3-TDM. Navigate to the System Status page using the associated button. The screen as shown in Figure 7.3

appears. Here the fault current and NGR voltage can be observed as well as the System Ground Fault and NGR Fault

statuses. TEST and RESET can be activated here, as well as pulsing.

Navigate to the Logging and Trending page using the associated button on the home screen. The Logging and Trend-

ing page is shown in Figure 7.4 below.

15

Navigate to the Settings page using the associated button on the home screen. The Settings page is shown in Figure

7.5 below. From here, the Sigma Settings page can be accessed. Select the system voltage (i.e. L-L voltage). Pulse

frequency can be selected. Settings for the alarm annunciation can be selected here as well.

Figure 7.1: Sigma 3 to Sigma3-TDM Connection Diagram

Figure 7.2: Home Screen

16

Figure 7.3: Status Screen

Figure 7.4: Event Log Page

Figure 7.5: Settings Page

17

Figure 7.6: Sigma and Alarm Settings Page

Figure 7.7: Pulse Contactor Settings Page

Figure 7.8: Communications Settings Page

18

The Sigma 3 has 4-wire RS-485 communications port to allow communications to a remote terminal or network, a

4-wire RS-485 communications port is provided at the bottom left of the Sigma 3. The 6-slot terminal block supplied

has screw terminals. Terminal # 1 must not be used. Only terminals 2, 3, 4, 5 and 6 are to be used as shown in Figure

8.1 below, with the preferred 4-wire connection in Figure 8.1(a) and the 2-wire connection in Figure 8.1(b). Note that

when the Sigma3-TDM is being used, communication connections to the system should be made through the

Sigma3-TDM. This is through the Sigma3-TDM TCP/IP communication port.

The protocol supported is MODBUS RTU. The MODBUS I/D number for the Sigma 3 is not programmable and is set

according to the serial number (see Table 8.1 below). The baud rate is not programmable and is set to 9600 BPS. The

frame set-up is 8 bit, no parity and 1 stop bit.

The communications cable should ideally be standard 4-wire with two twisted-pairs, and a grounding shield to prevent

electromagnetic interference. The shield of the cable between nodes should not be continuously grounded but should

be grounded at one end. The cable may be grounded at the Sigma 3 using the ground connection provided on termi-

nal # 6.

8. MODBUS COMMUNICATION

Figure 8.1 (a): Preferred 4-wire MODBUS Communication Connection

Table of contents

Other I-Gard Relay manuals