5

8.3 Battery Life................................................................................................................................49

8.4 Lithium Battery Safety ..............................................................................................................49

8.6 Battery Charging Status ............................................................................................................50

8.7 Battery Charging State..............................................................................................................50

8.8 Battery Status in System Registers ...........................................................................................50

9.1 Overview...................................................................................................................................51

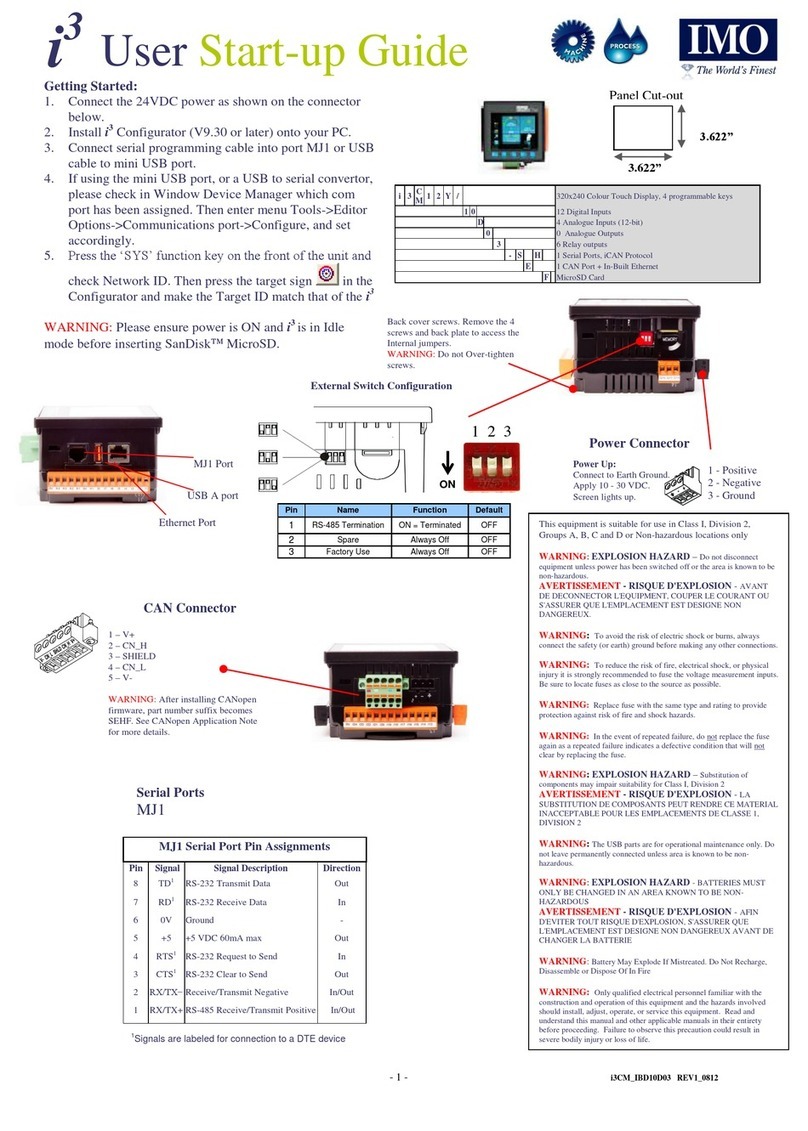

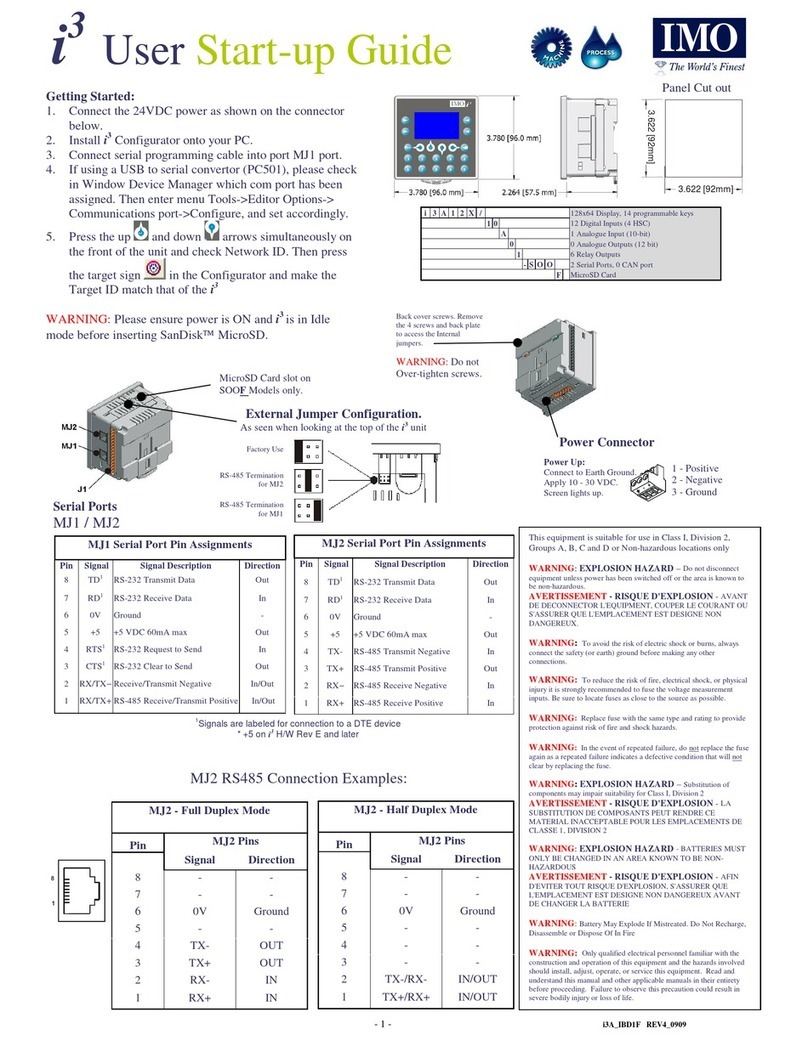

9.2 MJ1 Serial Port Pinout ..............................................................................................................51

9.3 i3 configurator Programming via Serial Port ............................................................................ 53

9.4 Ladder-Controlled Serial Communication ................................................................................ 53

CHAPTER 10: CAN COMMUNICATIONS ...............................................................................................54

10.1 Overview ...............................................................................................................................54

10.2 Port Description .................................................................................................................... 54

10.3 CAN Port Wiring ....................................................................................................................55

10.4 i3 configurator Programming via CAN .................................................................................. 57

10.5 Ladder-Controlled CAN Communication...............................................................................57

10.6 Using CAN for I/O Expansion (Network I/O) .........................................................................57

CHAPTER 11: ETHERNET COMMUNICATION .......................................................................................58

11.1 Ethernet Overview ................................................................................................................58

11.2 MAC Address .........................................................................................................................58

11.3 Ethernet Module Protocols and Features............................................................................. 59

11.4 Ethernet System Requirements ............................................................................................59

11.5 Ethernet Module Specifications............................................................................................59

11.6 Ethernet Module Configuration ............................................................................................ 60

11.7 Ethernet Configuration – IP Parameters...............................................................................63

11.8 Ethernet Module Protocol Configuration .............................................................................63

CHAPTER 12: DOWNLOADABLE COMMUNICATION PROTOCOLS .......................................................64

12.1 Overview ...............................................................................................................................64

12.2 Protocol Config...................................................................................................................... 66

11.3 Network Configuration.......................................................................................................... 67

12.4 Device List and Device Configuration.................................................................................... 69

12.5 Scan List.................................................................................................................................71

12.6 Data Mapping Configuration (Scan List Entry) ......................................................................72

CHAPTER 13: REMOVABLE MEDIA....................................................................................................... 74

13.1 Overview ...............................................................................................................................74

13.2 microSD Cards .......................................................................................................................74

13.3 microSD File System ..............................................................................................................74

13.4 Using Removable Media to Log Data .................................................................................... 75

13.5 Using Removable Media to Load and Save Applications ......................................................75

13.6 Removable Media (RM) Function Blocks in I3 configurator ................................................. 75

13.7 Filenames used with the Removable Media (RM) Function Blocks...................................... 76

13.8 System Registers used with RM ............................................................................................77

CHAPTER 14: FAIL-SAFE SYSTEM..........................................................................................................78

14.1 Overview ...............................................................................................................................78

14.2 Settings..................................................................................................................................78

14.3 Backup / Restore Data...........................................................................................................79

14.4 Autoload................................................................................................................................ 81

14.5 Autorun ................................................................................................................................. 82

CHAPTER 15: MAINTENANCE...............................................................................................................83