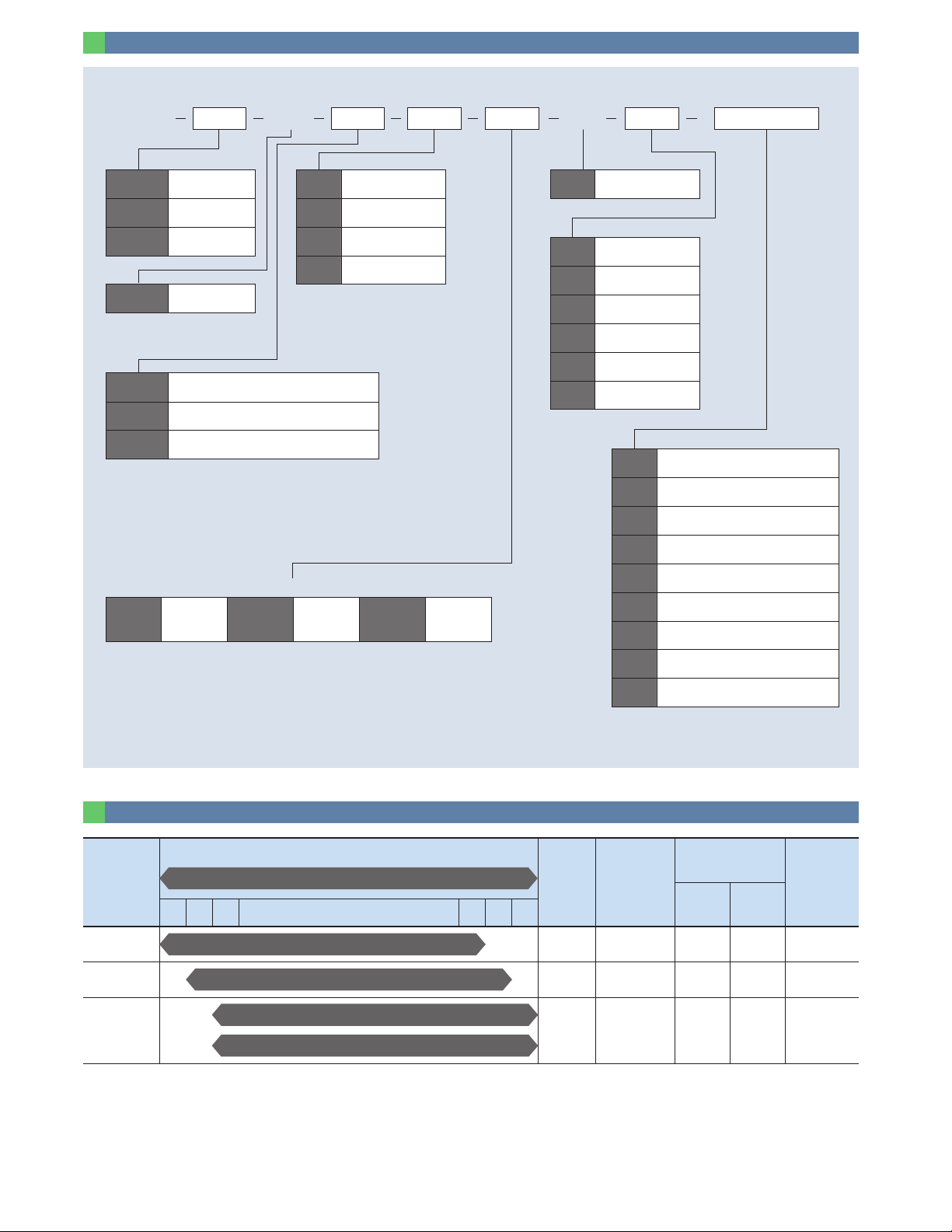

RCP6 ROBO Cylinder®

Item Description

Lead Ball screw lead (mm) 2.5

Horizontal

Payload

Maximum payload (kg)

(high-output enabled) 3

Maximum payload (kg)

(high-output disabled) 3

Speed /

acceleration/

deceleration

Max. speed (mm/s) 200

Rated acceleration/deceleration (G)

0.5

Max. acceleration/deceleration (G)

0.5

Vertical

Payload

Maximum payload (kg)

(high-output enabled) 3

Maximum payload (kg)

(high-output disabled) 3

Speed /

acceleration/

deceleration

Max. speed (mm/s) 200

Rated acceleration/deceleration (G)

0.5

Max. acceleration/deceleration (G)

0.5

Push

Max. push force (N) 300

Min. push force (N) 60

Max. push speed (mm/s) 10

Pull

Max. pull force (N) 300

Min. pull force (N) 60

Max. pull speed (mm/s) 10

Brake Brake specification Non-excitation actuating

solenoid brake

Brake holding force (kg) 3

Stroke

Min. stroke (mm) 110

Max. stroke (mm) 310

Stroke pitch (mm) 50

■Main Specifications

Item Description

Drive system Ball screw, φ8mm, rolled C10

Positioning repeatability ±0.02mm

Lost motion 0.1mm or less

Load cell rated capacity 600N

Loading repeatability (Note 6) ±1.0% F.S. (Note 7)

Ambient operating

temperature, humidity 0 ~ 40°C, 85%RH or less (no condensation)

Ingress protection IP20

Vibration & shock resistance 4.9m/s2

Overseas standards CE marking, RoHS directive

Motor type Stepper motor

Encoder type Battery-less absolute

Number of encoder pulses 8192 pulse/rev

(Note 6) Ratio (in percentage) of the load variations caused by the repeated operations to

the load cell rated capacity.

(Note 7) F.S.: Full Scale, the maximum measurable value.

■Tables of Payload by Speed/Acceleration

■High-output setting enabled (the unit for payload is kg)

Orientation Horizontal Vertical

Speed

(mm/s)

Acceleration (G)

0.5 0.5

0 3 3

40 3 3

85 3 3

130 3 3

150 3 3

200 3 3

■High-output setting disabled (the unit for payload is kg)

Orientation Horizontal Vertical

Speed

(mm/s)

Acceleration (G)

0.5 0.5

0 3 3

40 3 3

85 3 3

130 3 3

150 3 3

■Stroke and Max Speed

High-output

setting

Stroke (mm)

110 160 210 260 310

Enabled 200

Disabled 150

(Unit: mm/s)

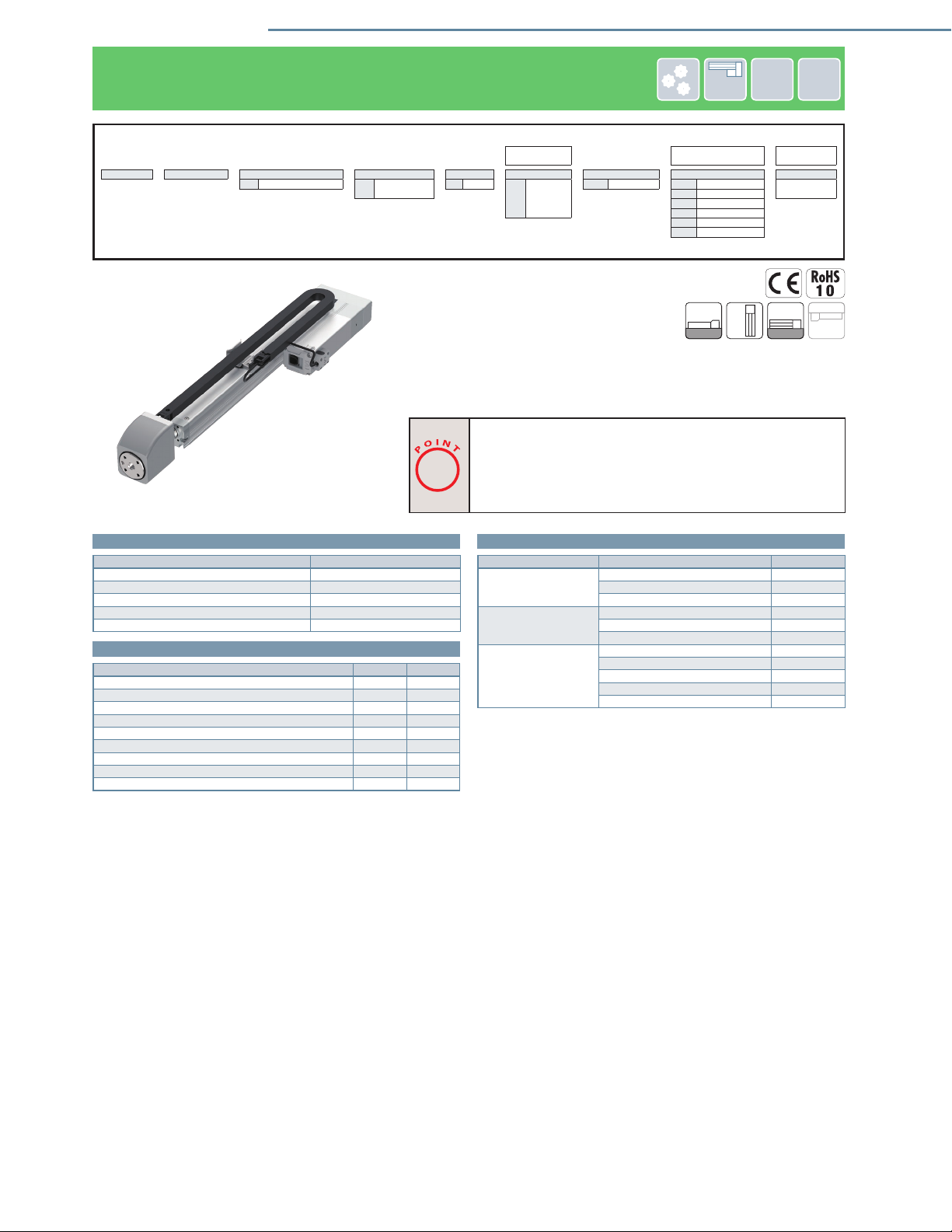

0

50

100

150

200

250

300

350

0 20 40 60 80 100

■C

orrelation diagram between push force and push command value

0

50

100

150

200

250

300

0 20 40 60 80 100

■C

orrelation diagram between pull force and pull command value

RCP6-RRA4R 6